Caution – Proface PS4800 - 19 Panel PC" User Manual

Page 53

PS-4600 Series User Manual

53

Installing the Industrial Personal Computer Unit

The installation gasket and installation fasteners are required when installing the

Industrial Personal Computer.

NOTE: The screw installation fasteners are required for Type 4X Indoor protection.

Follow the steps shown below when installing the Industrial Personal Computer:

Standard Models

CAUTION

OVERTORQUE AND LOOSE HARDWARE

Do not exert more than 0.5 Nm (4.5 lb-in) of torque when tightening the

installation fastener, enclosure, accessory, or terminal block screws. Tightening

the screws with excessive force can damage the plastic installation fastener.

When installing or removing screws, ensure that they do not fall inside the

Industrial Personal Computer chassis.

Failure to follow these instructions can result in injury or equipment damage.

Step

Action

1

Check that the gasket is correctly attached to the Industrial Personal Computer.

NOTE: When checking the gasket, avoid contact with the sharp edges of the

Industrial Personal Computer frame, and insert it completely into its groove.

2

Check whether the included mounting screws are screwed into the installation fas-

teners. If not, then the mounting screws must be screwed into the installation fas-

teners with a hex-head screwdriver. The mounting screws must only be screwed

in far enough that they no longer protrude above the installation fastener.

3

Install the Industrial Personal Computer in the panel opening (see page 50).

4

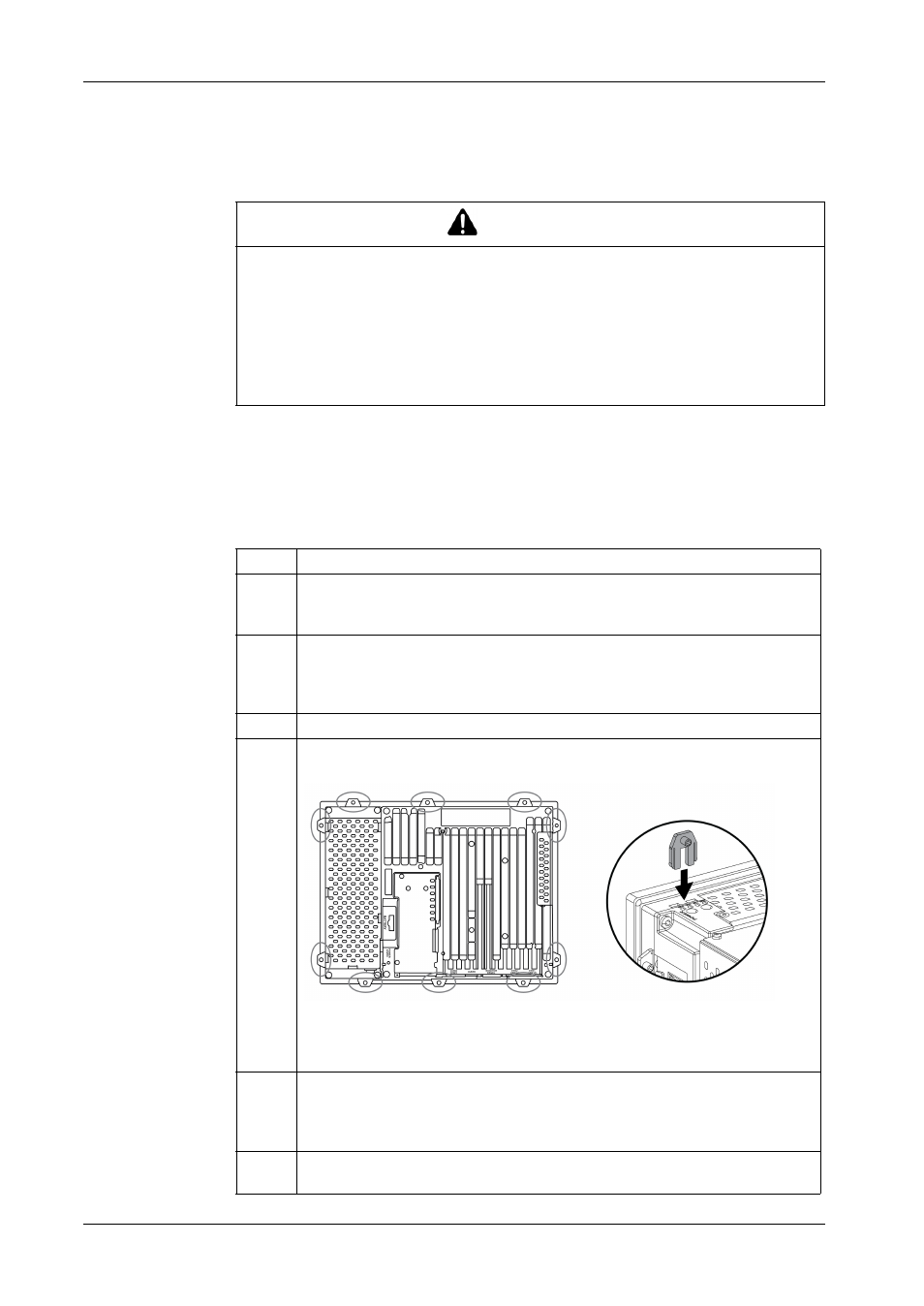

Insert each installation fastener securely into the slots at the top, bottom, left and

right side of the Industrial Personal Computer:

The number of slots is 10.

NOTE: You can purchase the installation fasteners as spare parts: reference

PFXZPPAF10P2.

5

Use a 2.5 hexagon head screwdriver to tighten each of the fastener screws and

secure the Industrial Personal Computer in place.

NOTE: To ensure a high degree of moisture resistance, use a torque of 0.5 Nm

(4.5 lb-in).

6

Ensure that the angle is tilted no more than mounting orientation requirements al-

low (see page 49).