Operation – Lincoln Electric IM10077 POWER FEED 25M User Manual

Page 60

B-44

OPERATION

B-44

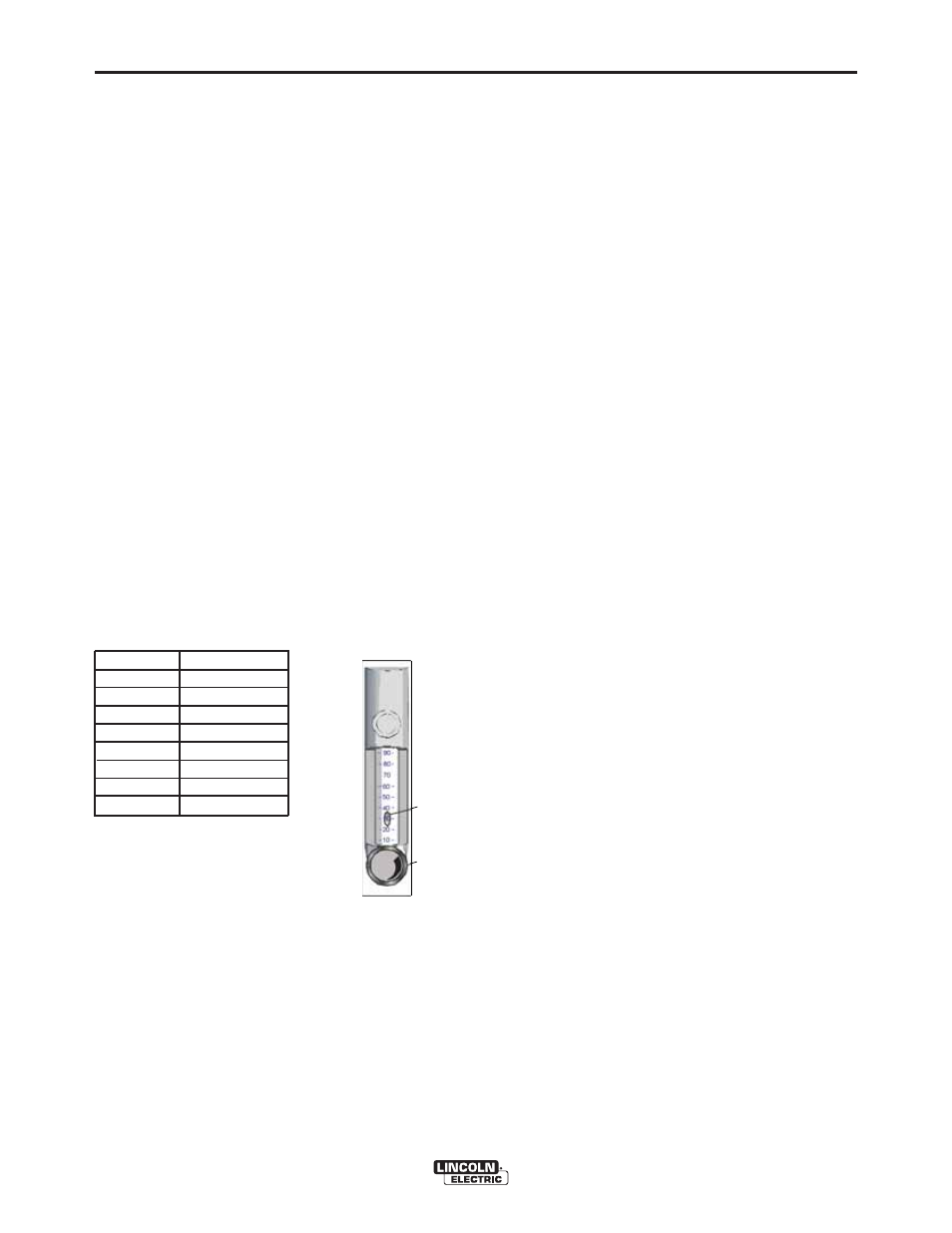

FLOW METER

The flowmeter shows the flow rate of shielding gas

and has a valve to adjust the flow. The flow meter is

scaled for CO

2

, Ar, and CO

2

/Ar blends. It is not cali-

brated and is for reference purposes only. The middle

of the ball indicates the flow rate of shielding gas.

Adjust the flow rate while depressing the GAS

PURGE switch by turning the valve at the bottom of

the meter. Most weld procedures require 25-40 scfh

(11.8 - 18.9 lpm) for sufficient shielding gas coverage.

Gun angle, nozzle diameter, joint configuration and

wind conditions may effect the amount of shielding

gas required.

When using a wire feeder with a flow meter, adjust the

regulator at the shield gas bottle or supply to a flow

rate that is higher than the flow rate indicated on the

feeder flow meter. Note that most regulators are cali-

brated based upon having low restrictions on the out-

let. The valve on the feeder flow meter creates a high

restriction and may cause errors in the readings at the

supply regulator. Set the gas flow rate using the

feeder flow meter reading and not the supply regulator

reading.

To achieve maximum flow rate, use a regulator with

30 psi or higher pressure compensation.

SCFH

Liter/Min.

10

4.7

20

9.4

30

14.2

40

18.9

50

23.6

60

28.3

70

33.1

80

37.8

POWER FEED™ 25M

Ball

Valve