Operation – Lincoln Electric IM10077 POWER FEED 25M User Manual

Page 46

B-30

OPERATION

B-30

POWER FEED™ 25M

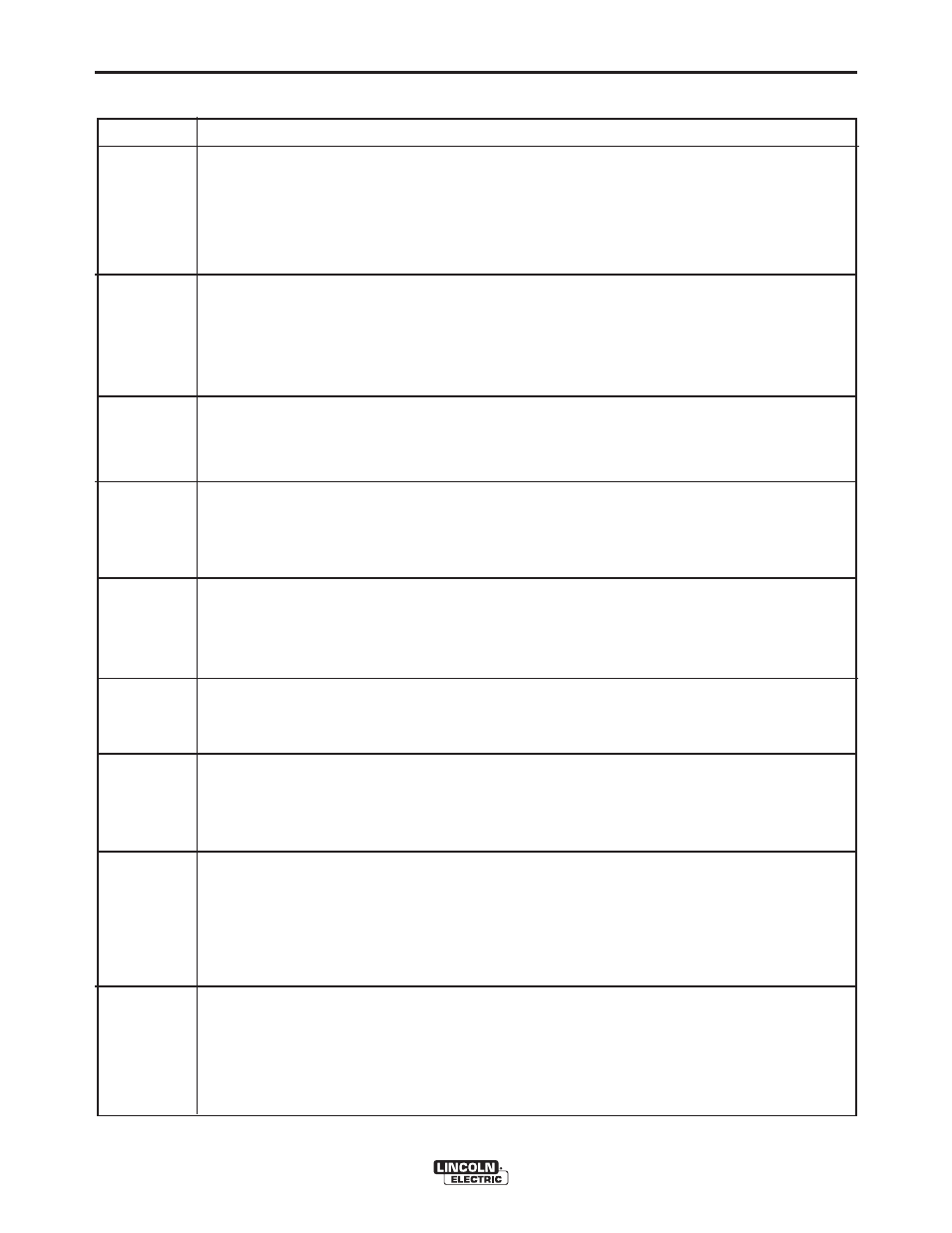

Parameter

Definition

P.103

View Software Version Information

Used for viewing the software versions for each board in the system. Press the Right Button to

enter the option. Rotate Control Knob to select the desired board to read. Press the Right

Button again to read the firmware version. Press the Left Button to back out to select another

board. Rotate the Control Knob to select another board, or press the Left Button to exit this

option.

P.104

View Hardware Version Information

Used for viewing the hardware version for each board in the system. Press the Right Button to

enter the option. Rotate Control Knob to select the desired board to read. Press the Right

Button again to read the hardware version. Press the Left Button to back out to select another

board. Press the Left Button again to exit this option.

P.105

View Welding Software Information

Used for viewing the Weld Set in the Power Source. Press the Right Button to read the Weld

Set version. Press the Left Button to back out and exit this option.

P.106

View Ethernet IP Address

Used for viewing the IP address of Ethernet compatible equipment. Press the Right Button to

read the IP Address. Press the Left Button to back out and exit this option. The IP address can-

not be changed using this option.

P.107

View Power Source Protocol

Used for viewing the type of power source the feeder is connected to. Press the Right Button to

identify the power source as either LincNet or ArcLink. Press the Left Button to back out and

exit this option.

P.350

User Interface Group Selection

Used to differentiate multiple PF25M feeders connected to the same power source. Each inde-

pendent feeder must have a unique selection in order to resolve error 18 problems.

P.500

View Lockout Parameters

Originally used to prevent inadvertent changes of secure setup parameters, P.500 was previ-

ously used as a gateway to these parameters. Presently, this option does not exist in any setup

menu.

P.501

Encoder Lockout

Locks one or both of the upper knobs (encoders), preventing the operator from changing wire

feed speed, amps, volts or trim. The function of each upper knob depends on the selected weld

mode. When a constant current weld mode is selected (e.g. Stick, TIG, Gouge), the upper right

knob will always function as an on/off switch. This parameter can only be accessed using

Power Wave Manager software.

P.502

Memory Change Lockout

Determines if the memories can be overwritten with new contents.

• No = Memories can be saved and limits can be configured (default).

• Yes = Memories cannot be changed - saving is prohibited and limits cannot be re-configured.

This parameter can only be accessed using Power Wave Manager.

USER DEFINED PARAMETERS