Operation, Smaw (stick) welding – Lincoln Electric IM10077 POWER FEED 25M User Manual

Page 23

B-7

B-7

POWER FEED™ 25M

OPERATION

SMAW (STICK) WELDING

SMAW is most often used for outdoor construction,

pipe welding and general repairs. The wire feeder

controls Amperage, Output Control and Arc Force dur-

ing SMAW welding.

During SMAW welding the wire drive remains idle.

NOTE: When a remote control pot such as a K936-1 or -2

Hand Amptrol is connected, and P.17 is setup for

Stick/Gouge Remote, the pot value will be shown

on the left display, but can only be adjusted to the

max workpoint. The max workpoint is set by adjust-

ing the left knob. When the left knob is adjusted,

the left display will show the max workpoint setting,

and will switch back to show the pot setting when

the knob is done being adjusted.

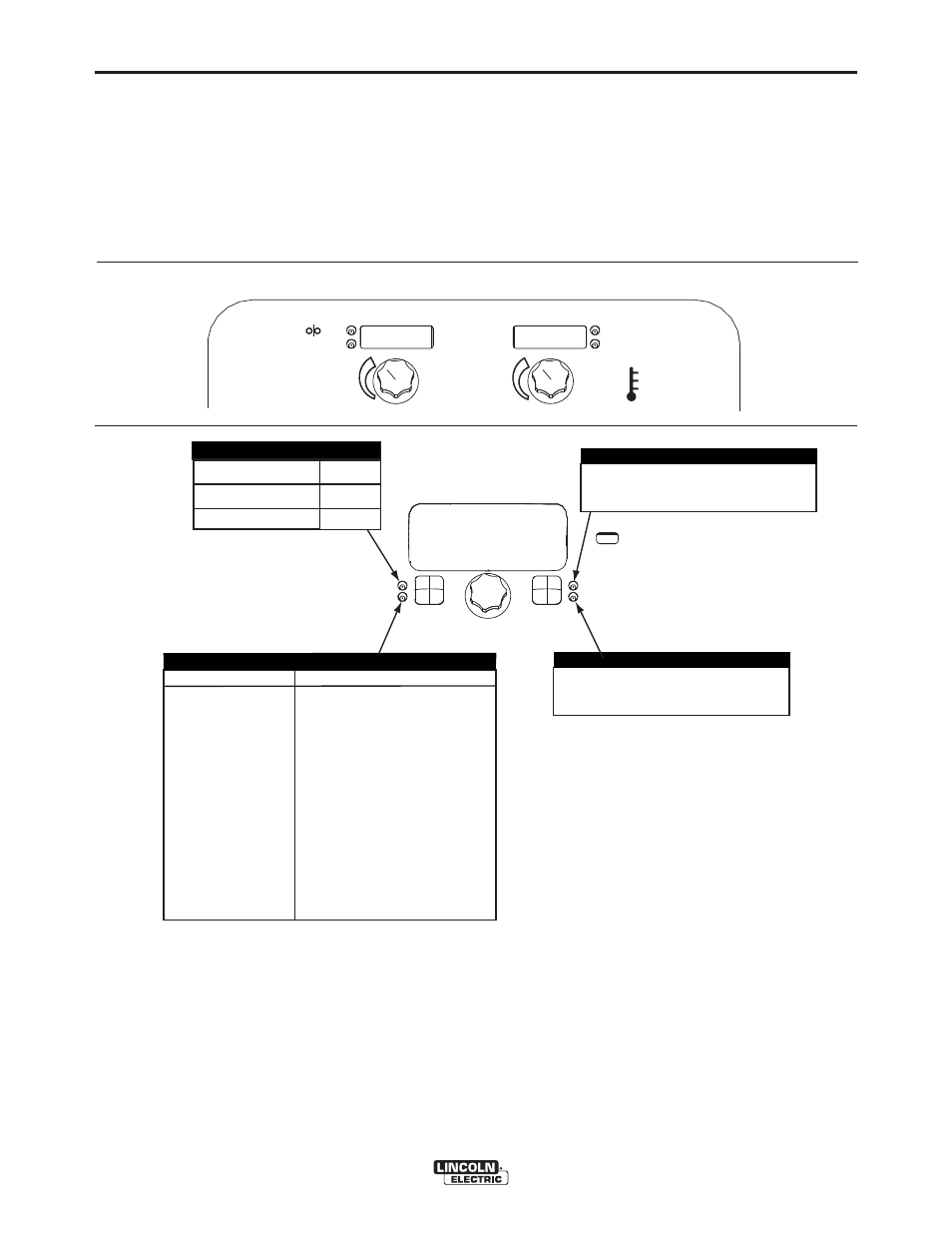

START OPTIONS

END OPTIONS

SETUP

EFFECT / RANGE

ARC FORCE

(Soft)-10.0 to

(Crisp)+10.0

DESCRIPTION

Arc Force adjusts the short cir-

cuit current for a soft arc, or for

a forceful, driving arc. It helps

to prevent sticking and shorting

of organic coated electrodes, par-

ticularity globular transfer types

such as stainless and low

hydrogen. Arc Force is espe-

cially effective for root pass on

pipe with stainless electrode

and helps to minimize spatter

for certain electrodes and pro-

cedure as with low hydrogen,

etc.

No arc ending options are active for

SMAW (Stick) welding modes.

END OPTIONS

UltimArc™ Control

WELD MODE

UltimArc™ Control

PROCESS

Stick Soft(7018)

Stick Crisp(6010)

MODE

1

2

CC STICK MODES

Stick Crisp

2

LESS

AMPS

MORE

AMPS

OUTPUT

OFF

OUTPUT

ON

+

+

194

0

AMPS

WFS

VOLTS

TRIM

n

No arc starting options are active for

SMAW (Stick) welding modes.

START OPTIONS

BASIC OPERATION

CONTROL OPTIONS