Operation – Lincoln Electric IM10077 POWER FEED 25M User Manual

Page 28

B-12

OPERATION

B-12

POWER FEED™ 25M

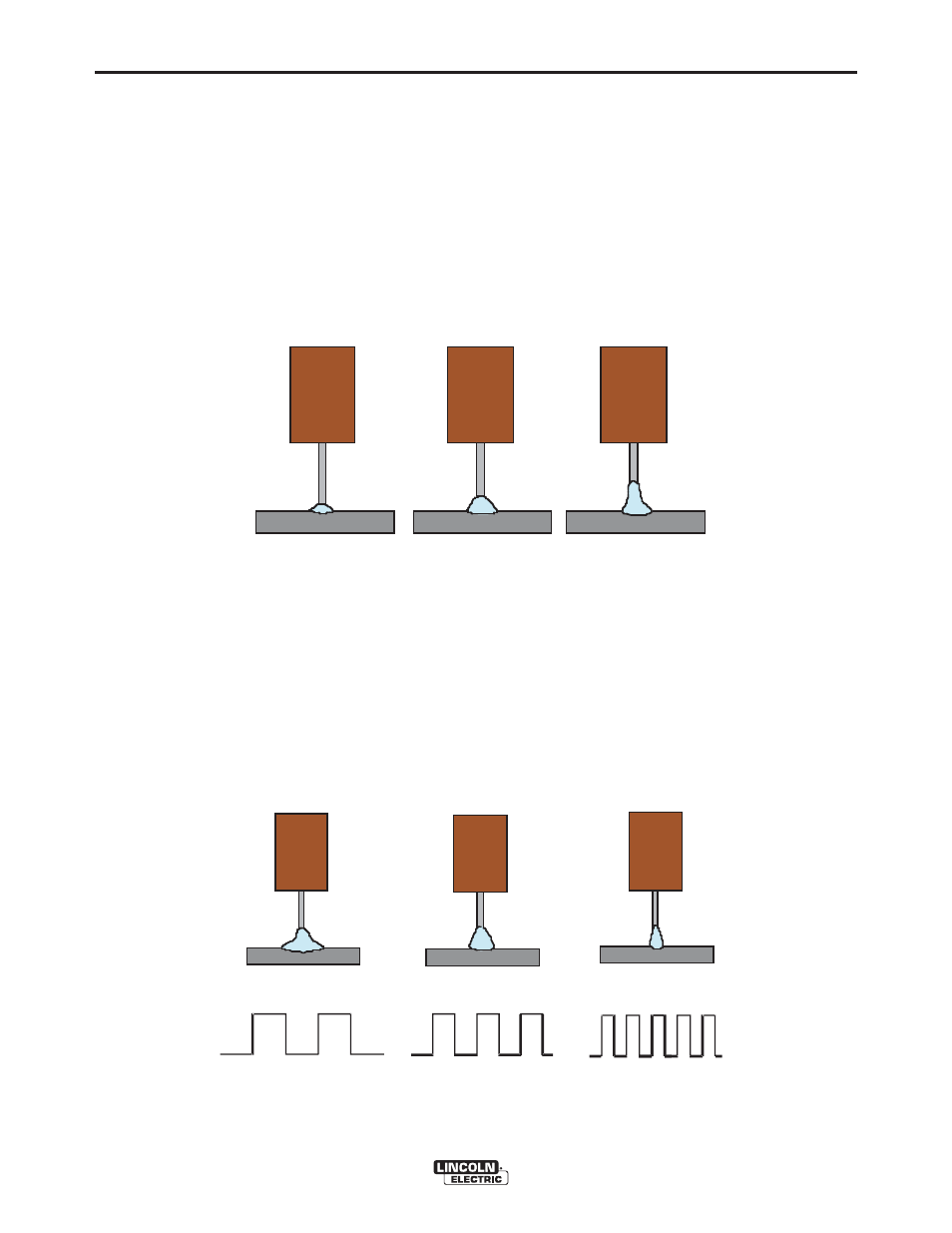

STEEL AND STAINLESS SYNERGIC GMAW-P (PULSED MIG) WELDING

Synergic GMAW-P (Pulsed MIG) welding is ideal for low spatter, out of position and reduced heat input applica-

tions. During pulse welding, the welding current continuously switches from a low level to a high level and then

back again. Each pulse sends a small droplet of molten metal from the wire to the weld puddle.

Pulse welding controls the arc length with 'Trim' instead of voltage. When trim (arc length) is adjusted, the Power

Wave automatically recalculates the voltage, current and time of each part of the pulse waveform for the best

result. Trim adjusts the arc length and ranges from 0.50 to 1.50. Increasing the trim value increases the arc

length, while decreasing the trim value decreases the arc length.

FIGURE B.6

ULTIMARC*

For steel and stainless pulse modes, UltimArc regulates the focus or shape of the arc. UltimArc values greater

than 0.0 increase the pulse frequency while decreasing the background current, resulting in a tight, stiff arc best

for high speed sheet metal welding. UltimArc values less than 0.0 decrease the pulse frequency while increasing

the background current, for a soft arc good for out-of-position welding.

FIGURE B.7

Trim .50

Arc Length Short

Trim 1.00

Arc Length Medium

Trim 1.50

Arc L ength Long

A rc Con tr ol OFF

Med ium Fr equency and Wi dth

Arc Control +10.0

Hi gh Frequency , Fo cu sed

A rc Con tr ol -10.0

Low Frequency, Wi de

*Wave Control in Power Wave® 355 and 455 machines.