Warner Electric Advanced Technology Tension Clutches User Manual

Page 5

5

Warner Electric • 800-234-3369

819-0339

3.

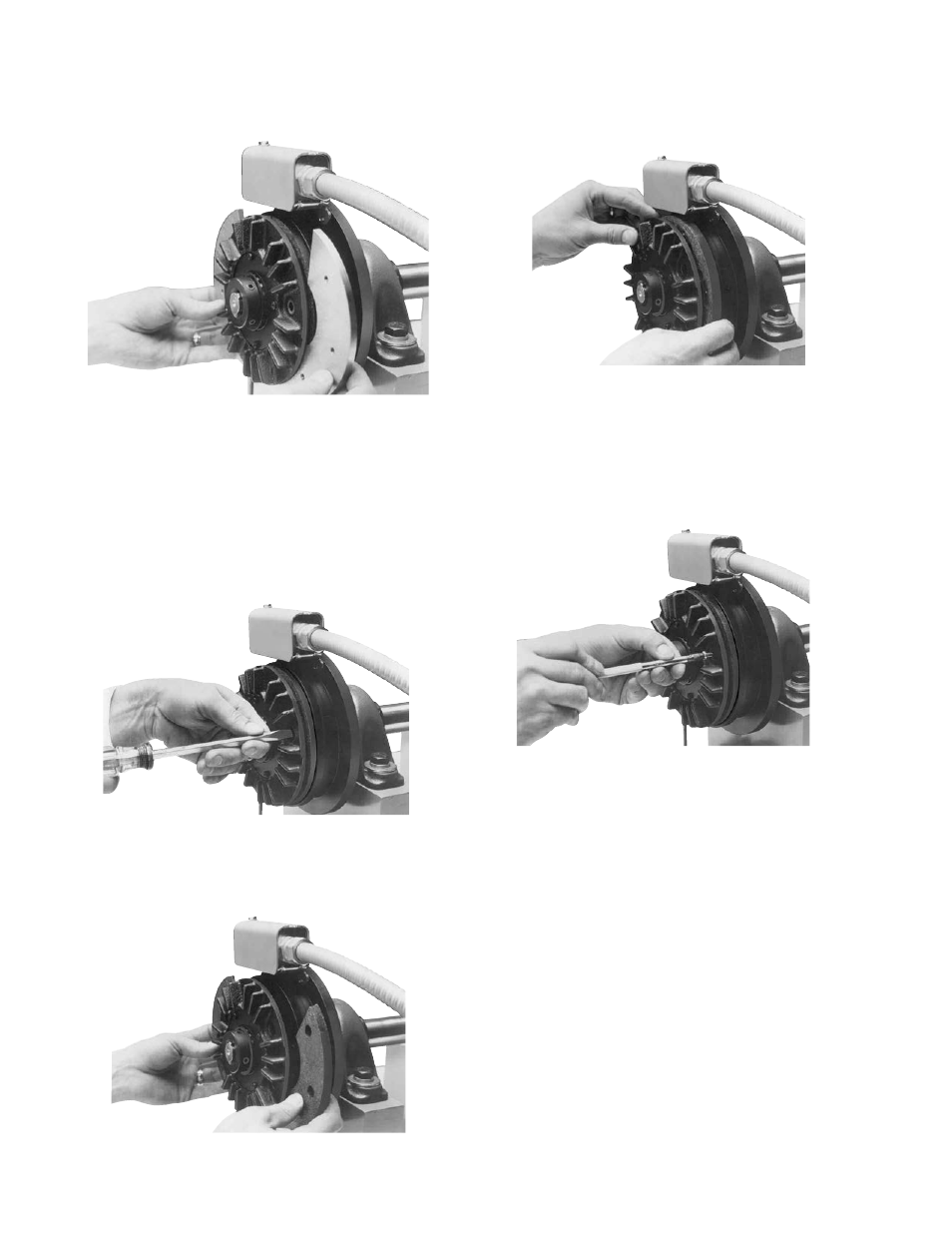

Lift out the two worn armature segments.

(See Figure 10)

Note: Although an AT brake is shown in these

instructions, identical procedures apply to a

clutch.

4.

Remove the screws that attach the friction mate-

rial segments to the clutch rotor through the

appropriate access holes. (See Figure 11)

5.

Lift out the worn friction material segments. (See

Figure 12)

Figure 10

Figure 11

6.

Insert two new friction material segments. The

recessed holes should be facing away from the

magnet body. (See Figure 13)

7.

Attach the new friction material segments to the

clutch rotor or brake magnet with screws through

the appropriate access holes. Apply one drop of

Loctite

®

(grade AA or equivalent) to each screw.

(See Figure 14)

Note: Use only the screws included with the

repair kit since any other screws may damage

the unit. Tighten screws to 18 to 22 inch pounds

torque.

Figure 12

Figure 13

Figure 14

- UNIBRAKE NEMA 4 (6 pages)

- UNIBRAKE (8 pages)

- ARC 2000 (16 pages)

- ARC Clutch_ZRC Top Load (18 pages)

- ZRC Clutch_ARC Top Load (18 pages)

- Dairy Cap Chuck (24 pages)

- Dairy Capping Headsets (10 pages)

- Autogap 475 & 650 (4 pages)

- Brushholder Installation (2 pages)

- Autogap 825-1225 (2 pages)

- Electro-Packs EP-170, 250, 400, 500, 825, 1000, 1525 (20 pages)

- Electro-Brake 375, 475, 650, 825, 1000, 1225 (20 pages)

- Electro-Clutch EC-375, EC-475, EC-650, EC-825, EC-1000, EC-1225 (20 pages)

- 5300-101-001 Collector Ring (2 pages)

- 5301-101-010 Collector Ring (2 pages)

- Brushholder Assembly and Mounting Dimensions (2 pages)

- SF_PB 400 (2 pages)

- SF_PB 250 (2 pages)

- Autogap 825-1525 (4 pages)

- Electro-Module EM-50, EM-100, EM-180, EM-210, EM-215 (22 pages)

- FB-375, 475, 650 (14 pages)

- 5200-101-012 Conduit Box Kit (4 pages)

- 5200-101-011 Conduit Box Kit (4 pages)

- 5200-101-010 Conduit Box Kit (4 pages)

- Recommended Electrical Installation Procedure for Warner Electric Clutches and Brakes (2 pages)

- EP-400 Vertical Mounting (2 pages)

- EP-250 Vertical Mounting (2 pages)

- Autogap 500 (4 pages)

- ER 825 and 1225 Normal Duty (16 pages)

- ER 825 and 1225 Heavy Duty (14 pages)

- ERS Electrically Released Brakes (6 pages)

- AT Brakes & Clutches Complete Brake Repair – On the Shaft, Sizes 25, 55, 115 (4 pages)

- AT Brakes (6 pages)

- AT Brake–Major Service Repair Instructions for Sizes 25, 55, 115 (9 pages)

- AT Clutch – Major Service Sizes 25, 55, 115 (12 pages)

- 5162-101-002 Conduit Box Kit (6 pages)

- Electrically Released Permanent Magnet Clutch Compatible Modules (4 pages)

- Electrically Released Motor Brake Module for EM-MBFB and EUM-MBFB (6 pages)

- Electrically Released Brake Module For EM-FBB and EUM-FBB (4 pages)

- Electrically Released Brake ER-375, ER-475, ER-650 (12 pages)

- Autogap 825-1525 Special Heavy Duty (4 pages)

- 5370-101-042 Conduit Box Kit (4 pages)

- Preassembled Clutch_Electrically Released Brake Module (7 pages)

- EUM-50_EUM-100_EUM-180_EUM-210_EUM-215 (16 pages)

- 5370-101-045 Conduit Box Kit (5 pages)