Warner Electric Advanced Technology Tension Clutches User Manual

Page 15

15

Warner Electric • 800-234-3369

819-0339

ATT Clutch Troubleshooting Guide

If performance problems are present after carefully following the instructions in this manual, use the

following checklist.

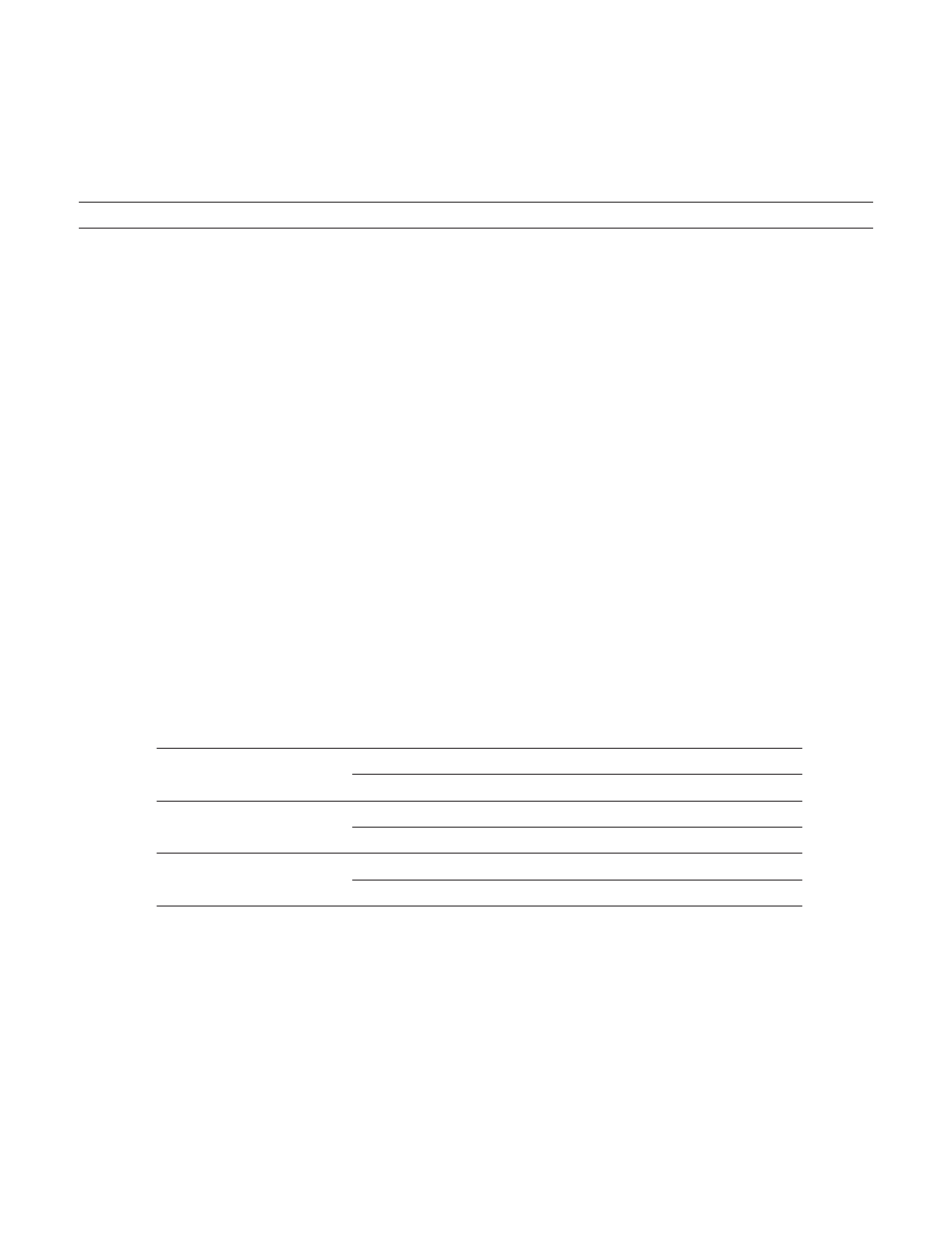

Symptom

Check

Problem

Possible Cause

Clutch Rotor will not move or engage when

• Coil Resistance

power is applied to the coil

Coil may be open. See Chart 1.

• Power Supply

Assure proper DC voltage is being delivered to the clutch.

• Airgap

If greater than .050” around entire periphery, reset gap.

Vibration

• Runout

Assure that shaft on which the clutch is mounted doesn’t have

excessive runout.

• Shaft Engagement

Assure adequate shaft length and diameter engagement in the hub.

Excessive Start or Stop Times

• Power Supply

Assure proper DC voltage is being delivered to the clutch.

• Adequate Burnishing

Unit must be run and cycled a few times to achieve full rated torque.

• Friction Surfaces

Replacement may be required.

• Friction Surfaces

Installation of replacement friction material or armature segments

may be incorrect and not allow full contact.

Clutch/Brake Size

Coil Voltage

Approx. Coil Resistance (Ohms)

25

24

20.6

90

290

55

24

19.6

90

230

115

24

16.5

90

182

Chart 1

- UNIBRAKE NEMA 4 (6 pages)

- UNIBRAKE (8 pages)

- ARC 2000 (16 pages)

- ARC Clutch_ZRC Top Load (18 pages)

- ZRC Clutch_ARC Top Load (18 pages)

- Dairy Cap Chuck (24 pages)

- Dairy Capping Headsets (10 pages)

- Autogap 475 & 650 (4 pages)

- Brushholder Installation (2 pages)

- Autogap 825-1225 (2 pages)

- Electro-Packs EP-170, 250, 400, 500, 825, 1000, 1525 (20 pages)

- Electro-Brake 375, 475, 650, 825, 1000, 1225 (20 pages)

- Electro-Clutch EC-375, EC-475, EC-650, EC-825, EC-1000, EC-1225 (20 pages)

- 5300-101-001 Collector Ring (2 pages)

- 5301-101-010 Collector Ring (2 pages)

- Brushholder Assembly and Mounting Dimensions (2 pages)

- SF_PB 400 (2 pages)

- SF_PB 250 (2 pages)

- Autogap 825-1525 (4 pages)

- Electro-Module EM-50, EM-100, EM-180, EM-210, EM-215 (22 pages)

- FB-375, 475, 650 (14 pages)

- 5200-101-012 Conduit Box Kit (4 pages)

- 5200-101-011 Conduit Box Kit (4 pages)

- 5200-101-010 Conduit Box Kit (4 pages)

- Recommended Electrical Installation Procedure for Warner Electric Clutches and Brakes (2 pages)

- EP-400 Vertical Mounting (2 pages)

- EP-250 Vertical Mounting (2 pages)

- Autogap 500 (4 pages)

- ER 825 and 1225 Normal Duty (16 pages)

- ER 825 and 1225 Heavy Duty (14 pages)

- ERS Electrically Released Brakes (6 pages)

- AT Brakes & Clutches Complete Brake Repair – On the Shaft, Sizes 25, 55, 115 (4 pages)

- AT Brakes (6 pages)

- AT Brake–Major Service Repair Instructions for Sizes 25, 55, 115 (9 pages)

- AT Clutch – Major Service Sizes 25, 55, 115 (12 pages)

- 5162-101-002 Conduit Box Kit (6 pages)

- Electrically Released Permanent Magnet Clutch Compatible Modules (4 pages)

- Electrically Released Motor Brake Module for EM-MBFB and EUM-MBFB (6 pages)

- Electrically Released Brake Module For EM-FBB and EUM-FBB (4 pages)

- Electrically Released Brake ER-375, ER-475, ER-650 (12 pages)

- Autogap 825-1525 Special Heavy Duty (4 pages)

- 5370-101-042 Conduit Box Kit (4 pages)

- Preassembled Clutch_Electrically Released Brake Module (7 pages)

- EUM-50_EUM-100_EUM-180_EUM-210_EUM-215 (16 pages)

- 5370-101-045 Conduit Box Kit (5 pages)