Warner Electric Advanced Technology Tension Clutches User Manual

Page 4

Complete Clutch Repair - On the Shaft

The new ATT design incorporates the latest in

advanced technology providing a rugged, durable,

patented design for long life, and maximum heat dis-

sipation. Patented, easy to replace, friction surfaces

extend the design life for continued like-new per-

formance. The ATT offers complete repair on the

shaft following ten easy steps. The repair can be

completed utilizing the parts in the friction face

replacement kit.

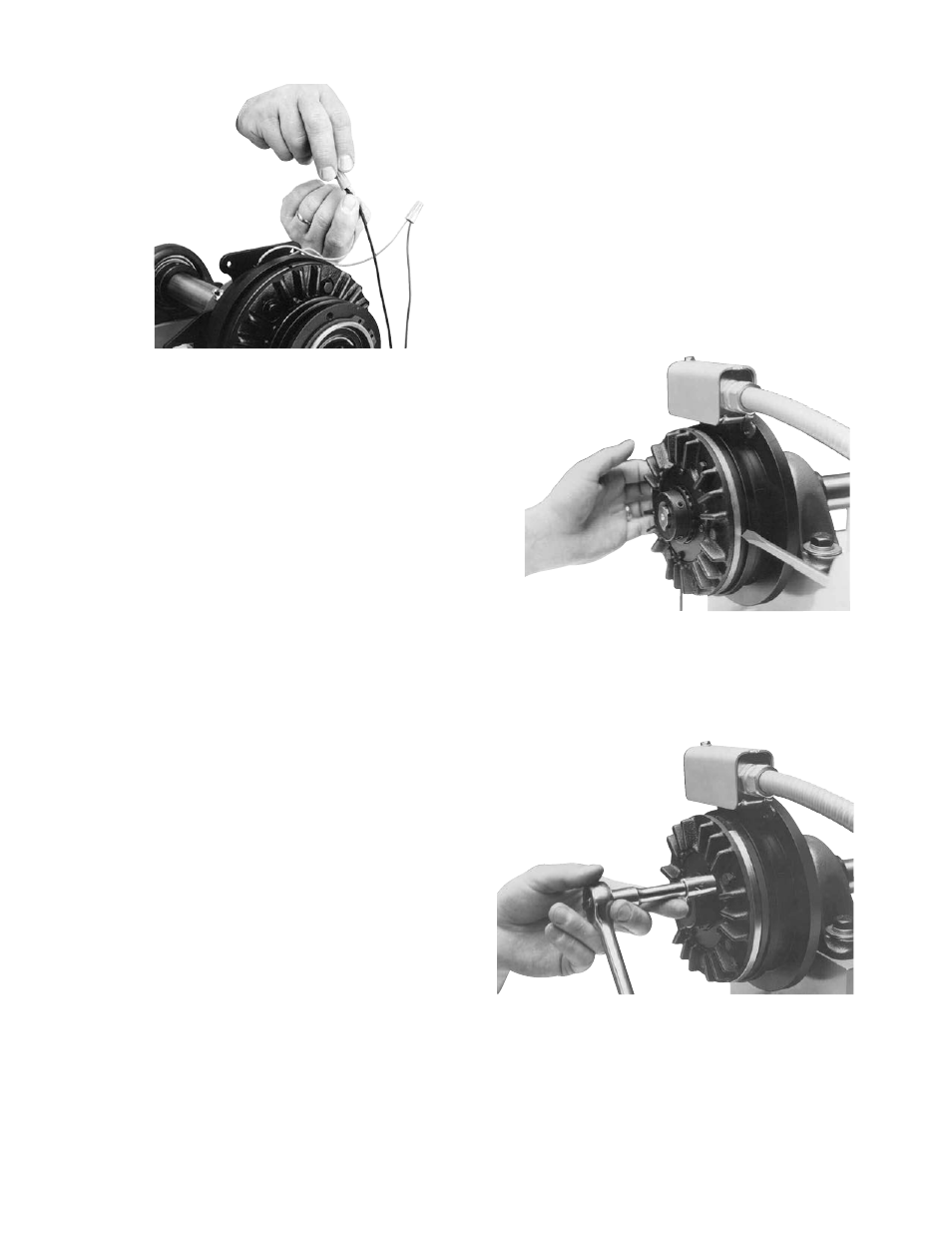

1.

Move the clutch rotor towards the field for disas-

sembly and reassembly. (See Figure 8)

2.

Remove hex head capscrews, washers and lock-

washers to loosen the armature segments from

the cast iron carrier.

(See Figure 9)

Figure 8

Figure 9

4

Warner Electric • 800-234-3369

819-0339

7.

Install the field restraining arm. (See Figure 6)

Note: The field must retain a degree of move-

ment freedom to compensate for bearing and

shaft alignment tolerances.

8. When using a Warner Electric tension con-

trol, follow the connection diagram supplied

with the control. (See Figure 7)

Note: If a Warner Electric TCS-210, -220, -310,

or – 320 control is used, add a 68 ohm, 25 watt

resister or a dummy coil (part no. 275-3843)

across the current sense circuit. Although the

TCS series controls are recommended, a MCS

control can be used with normal hook-up.

9.

Your ATT clutch is now ready for its static test.

Apply DC voltage to the clutch coil through the

clutch control. The armature should pull against

the friction material face.

10. Install the drive belt or chain.

11. Run the clutch under its operating load.

12. Your ATT clutch may not achieve its full torque

until after a short “break-in” period. To break in

the clutch, cycle it on and off under full load at

operating speed a minimum of ten times in quick

Figure 7