Warner Electric PCBC-500 Clutch_Brake Coupling User Manual

Page 7

7

Warner Electric • 800-825-9050

819-0484

PCC-500 Clutch-Coupling

Heavy Duty Spline Drive Armature

The illustration drawings, parts list, and exploded view

for this unit can be found on pages 28 and 29.

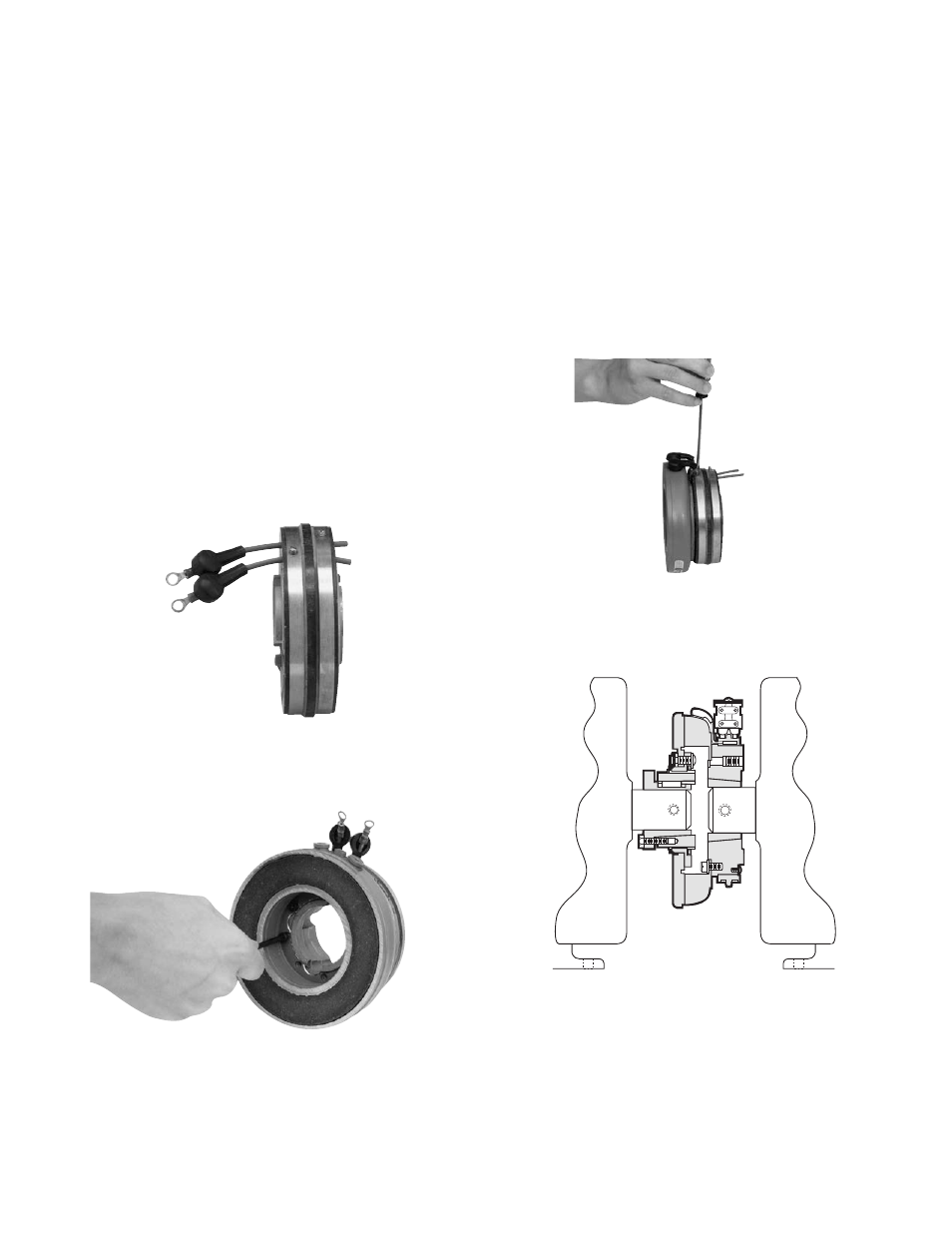

Either the magnet half of the clutch unit or the

armature half of the unit may be mounted on the shaft

first, depending on the characteristics of each

application. (Figure 4)

A. Assembling the Magnet and Magnet

Hub

1. Determine which side of the magnet hub will be

mounted to the magnet. The hub is reversible.

The side to be used will depend on which side

the taperlock bushing is to enter.

2. Insert the lead wires through the rubber

terminal caps and into the collector ring. The

wires should be inserted from the same side

of the ring that the magnet will be mounted on.

(Figure 1)

3. Mount the magnet to the magnet hub using

capscrews and lockwashers. (Figure 2)

Figure 1

4. Secure the lead wires to the magnet

terminals with screws and lockwashers.

5. Pull the rubber terminal caps over the

terminals.

6. Pull the excess lead wire length from the back-

side of the collector ring (away from the mag-

net) until the wire is snug.

7. Tighten down the screw in the collector ring.

The sharp cone point on the screw should

pierce the lead wire insulation to make a good

electrical contact. The head of the screw should

be below the surface of the collector ring.

(Figure 3)

8. Cut off the excess wire.

Figure 2

Figure 3

Figure 4 - PCC Clutch Coupling