Warner Electric PCBC-500 Clutch_Brake Coupling User Manual

Page 12

PCBC-500 Heavy Duty Spline Drive

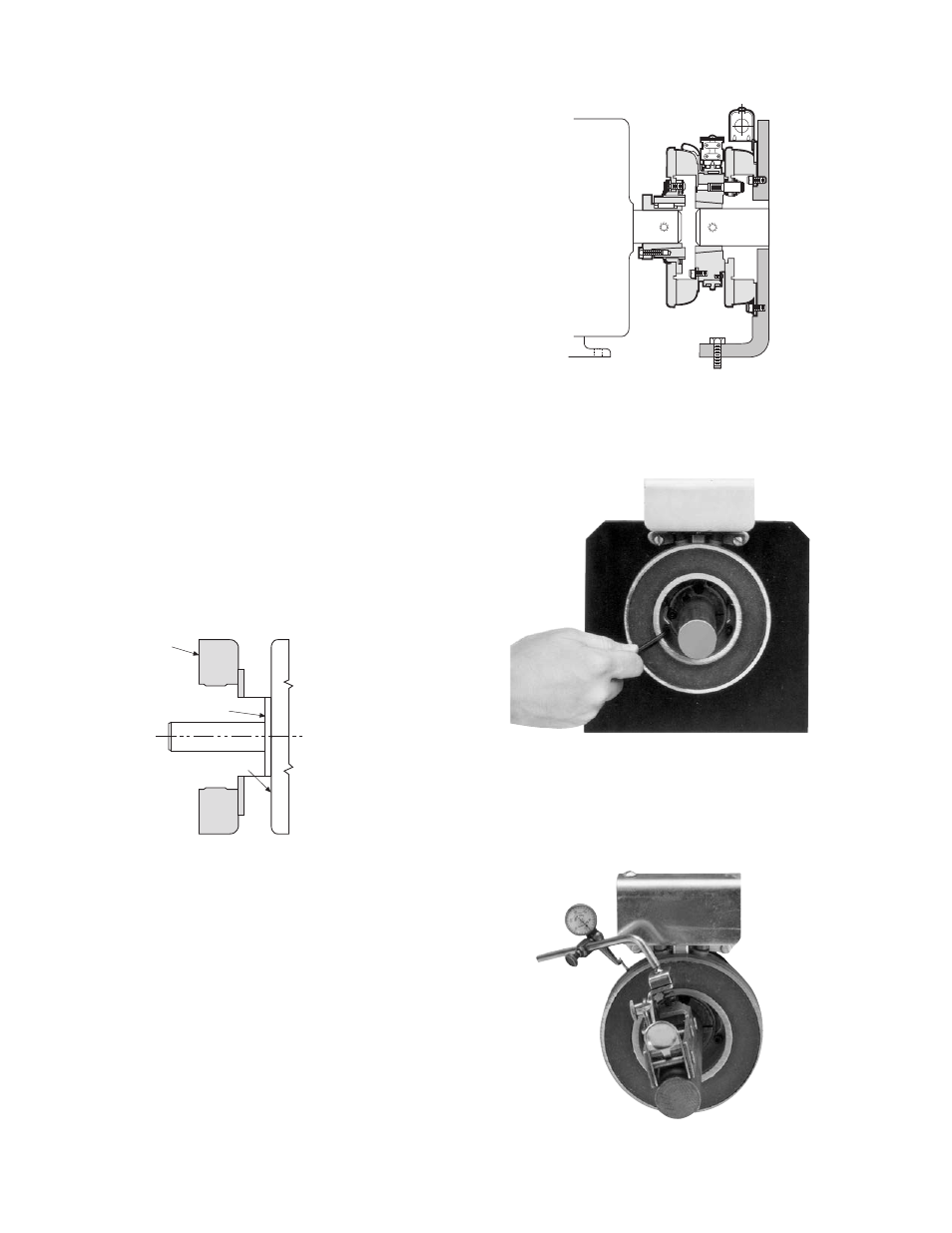

Armature Clutch/Brake Coupling (Figure 2)

The illustration drawing, parts list, and exploded view for

this unit can be found on pages 32 and 33.

A. Installing the Conduit Box

Install the conduit box on the magnet. Instructions for

this procedure can be found on page 20.

B. Mounting the Magnet

The brake half of the clutch/brake unit is usually installed

first; however, in some cases it may be

necessary to start with the clutch portion of the unit

to assure a proper assembly when complete.

The brake magnet is mounted to a stationary machine

member by a flange. Extreme care must be taken in

se lect ing the location for the mounting of the magnet.

Proper positioning is very important for the unit to

function correctly.

1. A pilot diameter on the mounting surface is

essential to hold the magnet within the required

tolerances. (Figure 1) Also see “Customer Shall

Maintain” on page 32.

2. A machined pilot diameter is provided on the

magnet mounting flange (refer to illustration

drawings on page 32) to aid in the proper

positioning of the magnet.

Field

Pilot Diameter

Mounting Surface

Figure 1

3. Once the mounting surface has been

prepared, the magnet is bolted in place with

capscrews and lock-washers. (Figure 3)

4. Use a dial indicator to check the unit for

concentricity and squareness to the shaft.

The unit should be concentric within .010 T.I.R.

and square within .006 T.I.R.

(Figure 4)

Figure 3

Figure 4

Figure 2 - PCBC Clutch/Brake Coupling

Warner Electric • 800-825-9050

819-0484

12