Warner Electric PCBC-500 Clutch_Brake Coupling User Manual

Page 6

Note:

This position must not be disturbed during

completion of as sem bly. (Figure 11)

D. Mounting the Armature Assembly

1. Slide the armature assembly onto the shaft.

Keep adjustment in Step 5 (Figure 11) from

moving.

2. If the magnet and magnet hub assembly

has been secured to the shaft first, then adjust

the armature's position to allow approximately

1/32" between the two faces. (Figure 12)

Once this 1/32" gap has been set, it will be

automatically maintained throughout the life of

the unit.

3. Secure the assembly in this position on the

shaft.

E. Mounting the Brushholder

1. The brushholder is mounted on a bracket which

must be furnished by the customer.

The bracket must be firmly secured to

prevent vibration which could cause

im proper contact between the brushes and col-

lector ring.

2. The distance from the centerline of the shaft to

the top of the brushholder should be 4".

Maintaining this dis tance will assure proper

spring tension on the brushes and maximum

wear follow-up. A detailed dimensional

drawing is included with each brushholder.

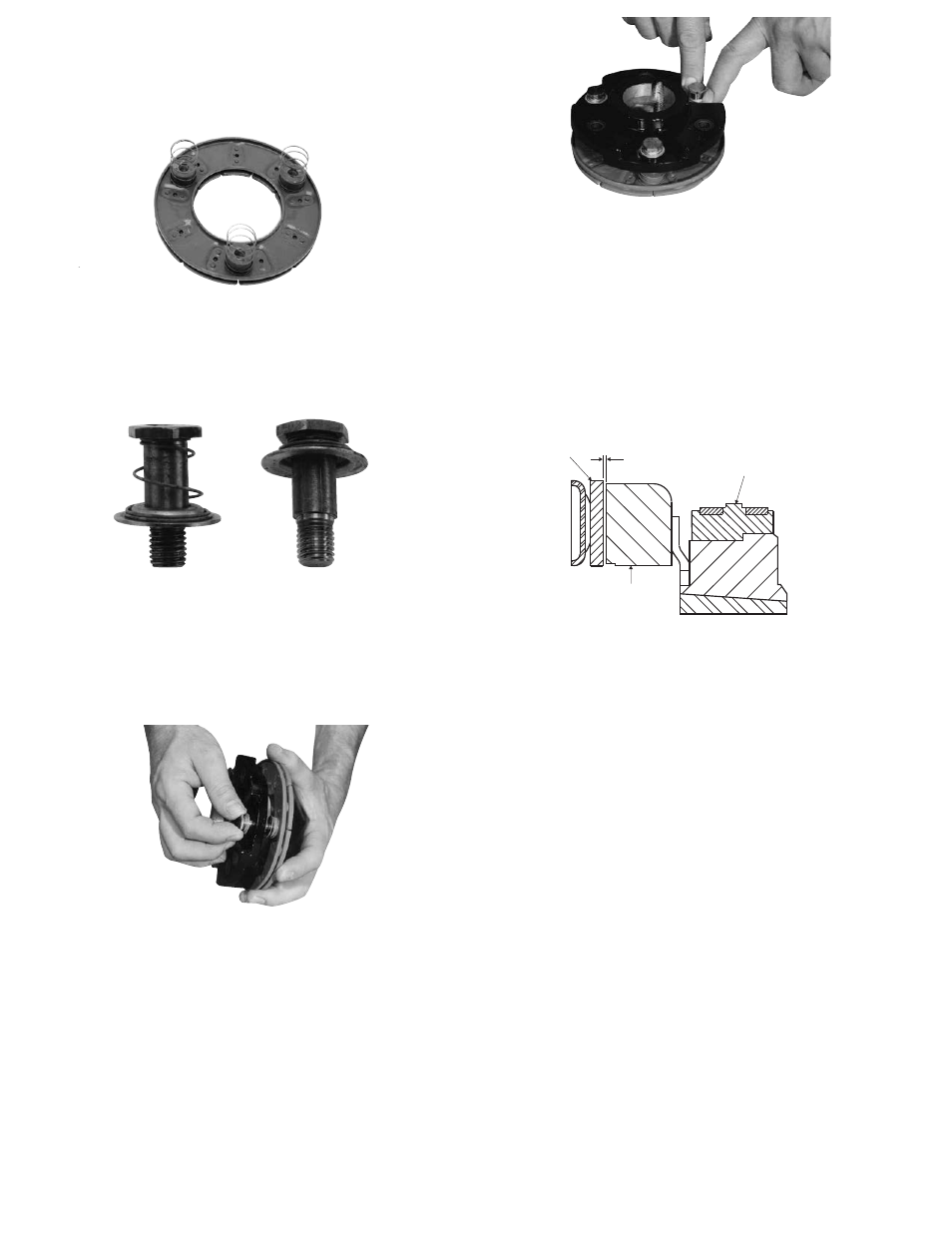

Step 1

Place straight springs over armature

bosses on back side of armature (Figure 8).

Step 2

Compress conical spring against retainer ring

by sliding detent spring towards head of pin.

(All 3 pins.) (Figure 9)

Step 3

Insert assembled drive pins through

(customer-supplied part (Figure 5) through the

straight springs, and into the threaded arma-

ture bosses. Apply grade "AA" Loctite Sealant

on drive pin threads. (Figure 10)

Step 4

Tighten drive pins until shoulders of pins are

against face of armature bosses. Since

threads are class No. 3 fit, pins may seem to

bind.

Step 5

Compress the retainer rings against the arma-

ture hub (or customer-supplied part), and

check to see that the part is held

tightly to the armature bosses.

6

Warner Electric • 800-825-9050

819-0484

Figure 11

1/32-inch

Armature

Magnet

Magnet Hub

Figure 12

Figure 8

Figure 9

Figure 10