Warner Electric PCBC-500 Clutch_Brake Coupling User Manual

Page 15

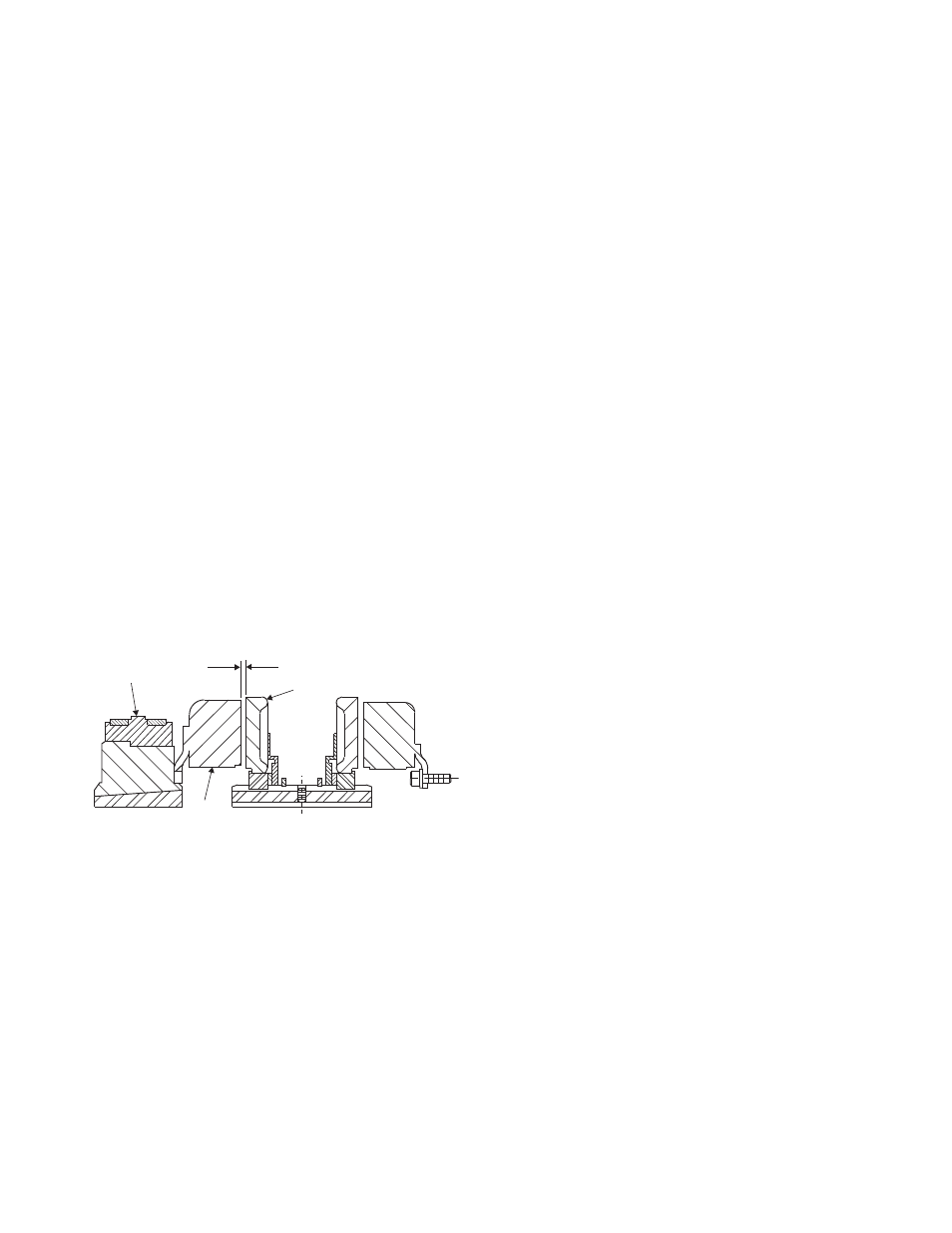

F. Mounting the Magnet and Magnet Hub

The magnet and magnet hub are mounted on the shaft

with a taperlock bushing. All parts must be clean and

free from burrs and chips before assembling.

1. Place the bushing into the hub and insert the

key. The key is a side-to-side fit and should not

contact the top of the keyway.

2. Insert the locking setscrews loosely into the

bushing and slide the assembly onto the shaft.

3. Adjust the magnet's position to allow a gap of

about 1/16 inch between the magnet face and

the armature face.

4. Secure the magnet's position on the shaft by

alternately tightening each setscrew with a

torque wrench to 175 in. lbs. torque. During the

tightening process the bushing should be

tapped lightly to make certain it seats-in

properly.

5. Set the autogap by pressing the armature

into contact with the magnet face and then

releasing it. The armature should spring back

about 1/32 inch. (Figure 11)

This gap will be automatically maintained for the

life of the unit.

1/32-inch

Armature

Magnet Hub

Magnet

Figure 11

G. Mounting the Brushholder

1. The brushholder is mounted on a bracket which

must be furnished by the customer. The

bracket must be firmly secured to prevent

vibration which could cause im proper contact

between the brushes and collector ring.

2. The distance from the centerline of the shaft to

the top of the brushholder should be 4".

Maintaining this dis tance will assure proper

spring tension on the brushes and maximum

wear follow-up. A detailed dimensional

drawing is included with each brushholder.

Warner Electric • 800-825-9050

819-0484

15