Warner Electric Electro-Module EM-50, EM-100, EM-180, EM-210, EM-215 User Manual

Page 6

6

Warner Electric • 800-825-9050

P-213 • 819-0303

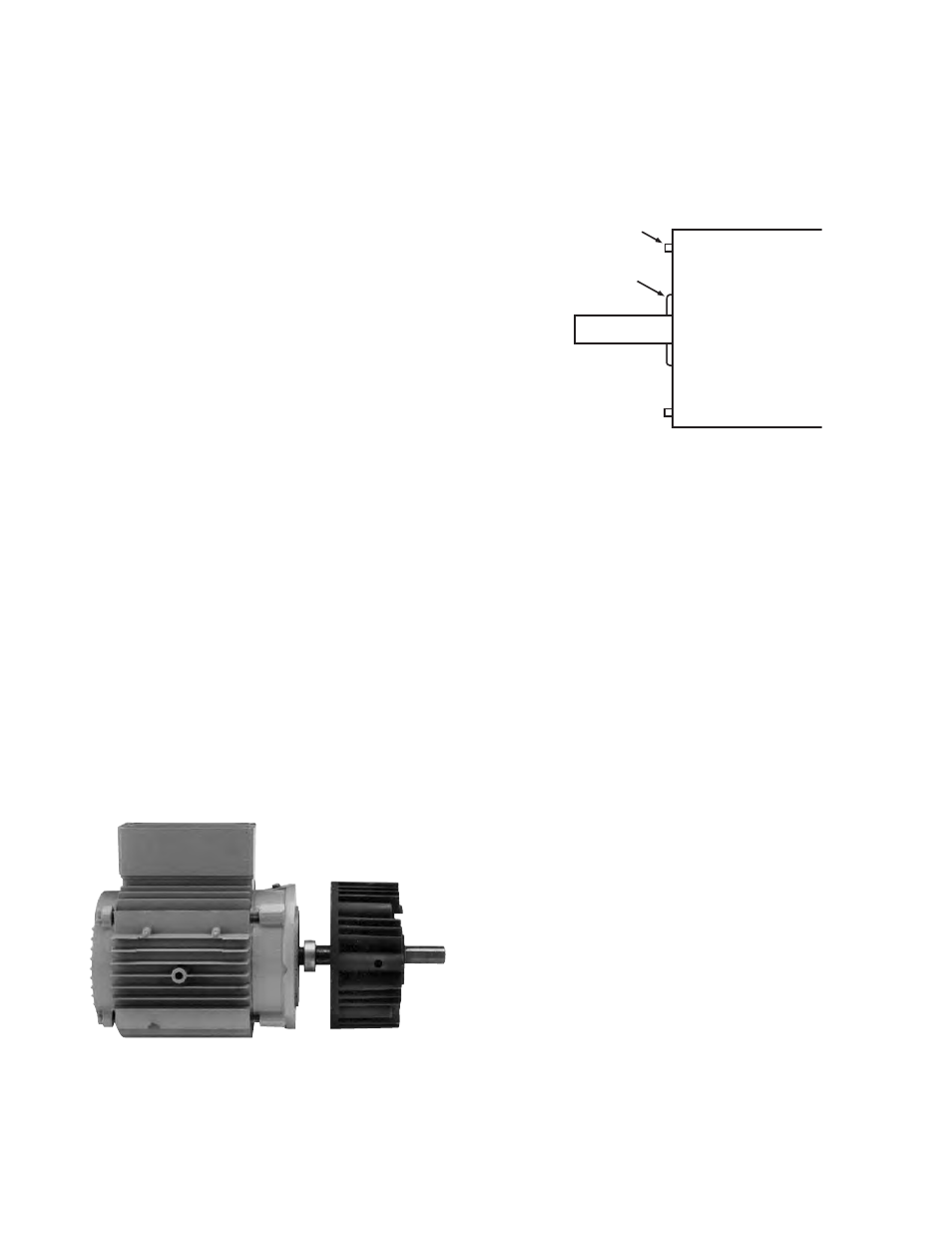

3. When using the EM-180-20 a possible inter-

ference may exist between the splined arma-

ture hub and some motors. (See Figure 10) A

spacer ring is provided with the EM-180

mounting accessory to provide the necessary

running clearance.

Figure 10

Place the spacer ring between the brake

module housing and the C-face of the motor

when bolting the two units together.

4. Align the motor shaft and key with the mating

shaft hole and key slot in the brake module.

5. Secure brake module to the motor C-face with

the four (4) long 3/8-inch hex head capscrews.

Section E: Installing the Motor Mount (M)

A Motor Mount (M) can be installed to the brake

or output clutch module to provide a foot mount-

ing for the complete assembly of module and

motor.

1. Remove the two (2) long hex head bolts from

the side of the module toward the ventilation

holes.

2. Mount the module on the Motor Mount so that

the base of the Motor Mount is underneath

the modules and motor. (See Figure 11) A pilot

diameter on the module mates with a pilot

diameter on the Motor Mount.

This is a three step process.

1. Simply slide the screwdriver through the

window and press the armature toward its mat-

ing friction surface.

2. Rotate the output of the unit. The rotor and the

window should stay in place when you do this.

Only the armatures will move. Rotating the

rotor will move the window.

3. Repeat steps 1 & 2 to ensure that the airgap

between armature and its mating friction sur-

face is about 1/32” and that the armature is

kept square. (If the armature is cocked, it may

engage on one rim, giving the appearance of

engagement but failing to provide full torque.)

Section D: Mounting the Brake to a Motor

The brake module (20) can be mounted directly

to a motor.

1. Insert a key in the motor shaft keyway. Prick

punch the end of the (EM-50 and EM-100)

motor shaft keyway to prevent the key from

sliding out.

2. A set collar is provided in the EM-180 and

EM-210 mounting accessory to prevent the

key from sliding out. Slide the set collar up

against the motor bearing and tighten the

setscrew securely. (Figure 9)

Figure 9

C-face mounting

If this boss extends

beyond the C-face

surface use the

spacer.

Do not use spacer

if boss is below the

C-face surface.