Warner Electric Electro-Module EM-50, EM-100, EM-180, EM-210, EM-215 User Manual

Page 5

5

Warner Electric • 800-825-9050

P-213 • 819-0303

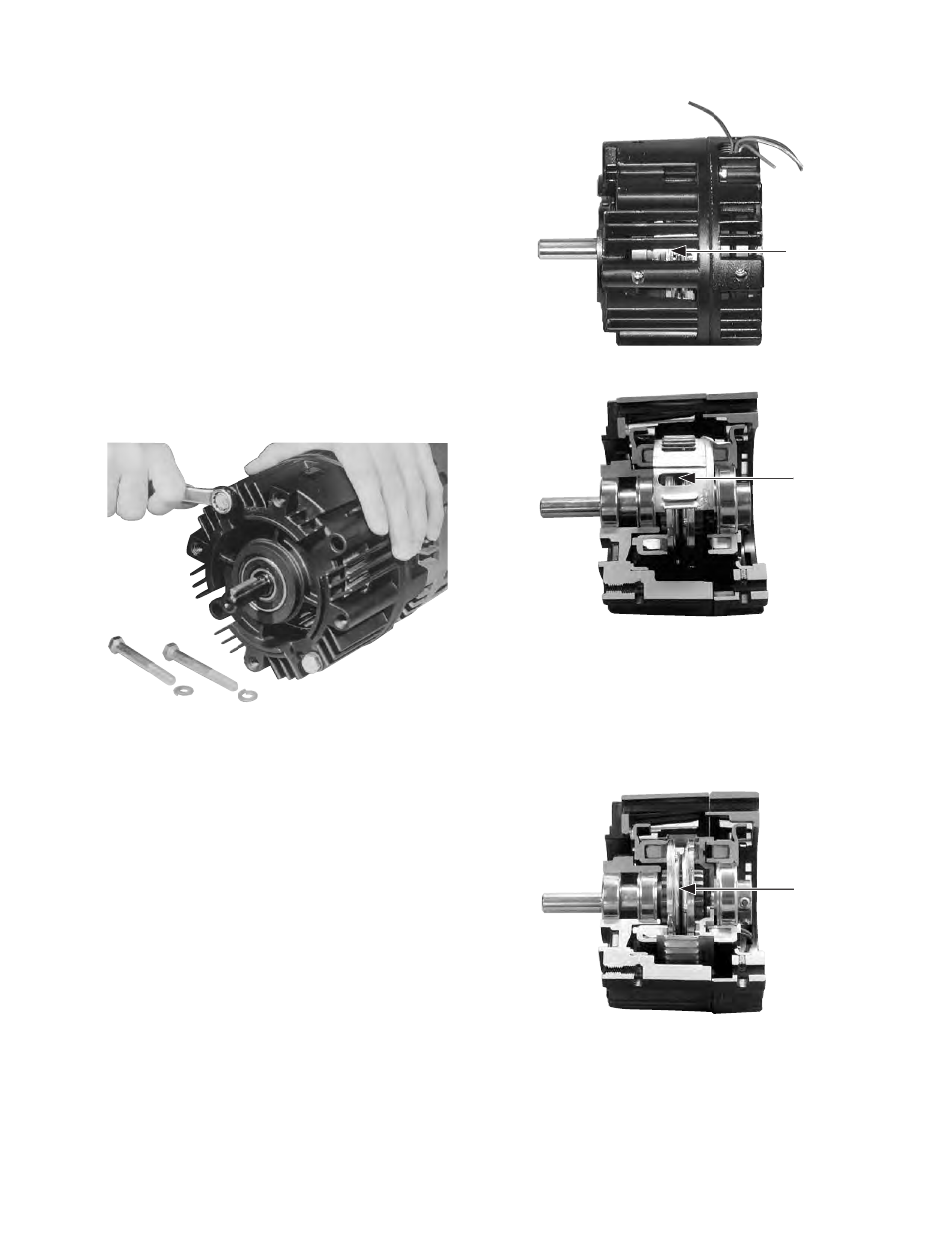

Section B: Bolting Two Modules Together

The brake module (20) and/or output clutch

module (40) may be assembled to the mounted

motor clutch module (10) or the input clutch (30).

1. Position the modules so that, in the usual

horizontal position, the ventilation holes are

down to prevent foreign matter from falling

into the units.

2. Bolt the modules together with the long hex

head bolts that are provided, see figure 5.

Mating pilot diameters assure proper align-

ment between module assemblies.

3. Proceed to Section C

Figure 5

Section C: Adjusting Airgap

For new installations it is necessary to adjust the

airgap between the friction faces of the clutch

and/or brake.

To set the airgap for an Electro-Module (EM) you

will need to access the armatures. On an EM

there are gaps between the fins on the housing

on 1/2 of the unit circumference. When looking

through this gap, you will see the fan on the

clutch rotor. In that fan there is a 1/2 x 1 inch

window. It is possible to look inside the unit and

see the armatures by looking through this win-

dow. When looking through this window you will

be looking between the two armatures of a

clutch/brake unit as shown in figures 6 and 7.

Figure 6

Figure 7

If the armature for either the clutch or the brake

is too far away from its mating friction surface, it

is possible to move this back into adjustment

using a flat blade screwdriver between the two

armatures. See figure 8.

Figure 8