Warner Electric Electro-Module EM-50, EM-100, EM-180, EM-210, EM-215 User Manual

Page 4

4

Warner Electric • 800-825-9050

P-213 • 819-0303

Installation Instructions

Section A: Mounting the Motor Clutch Module

(10 Module)

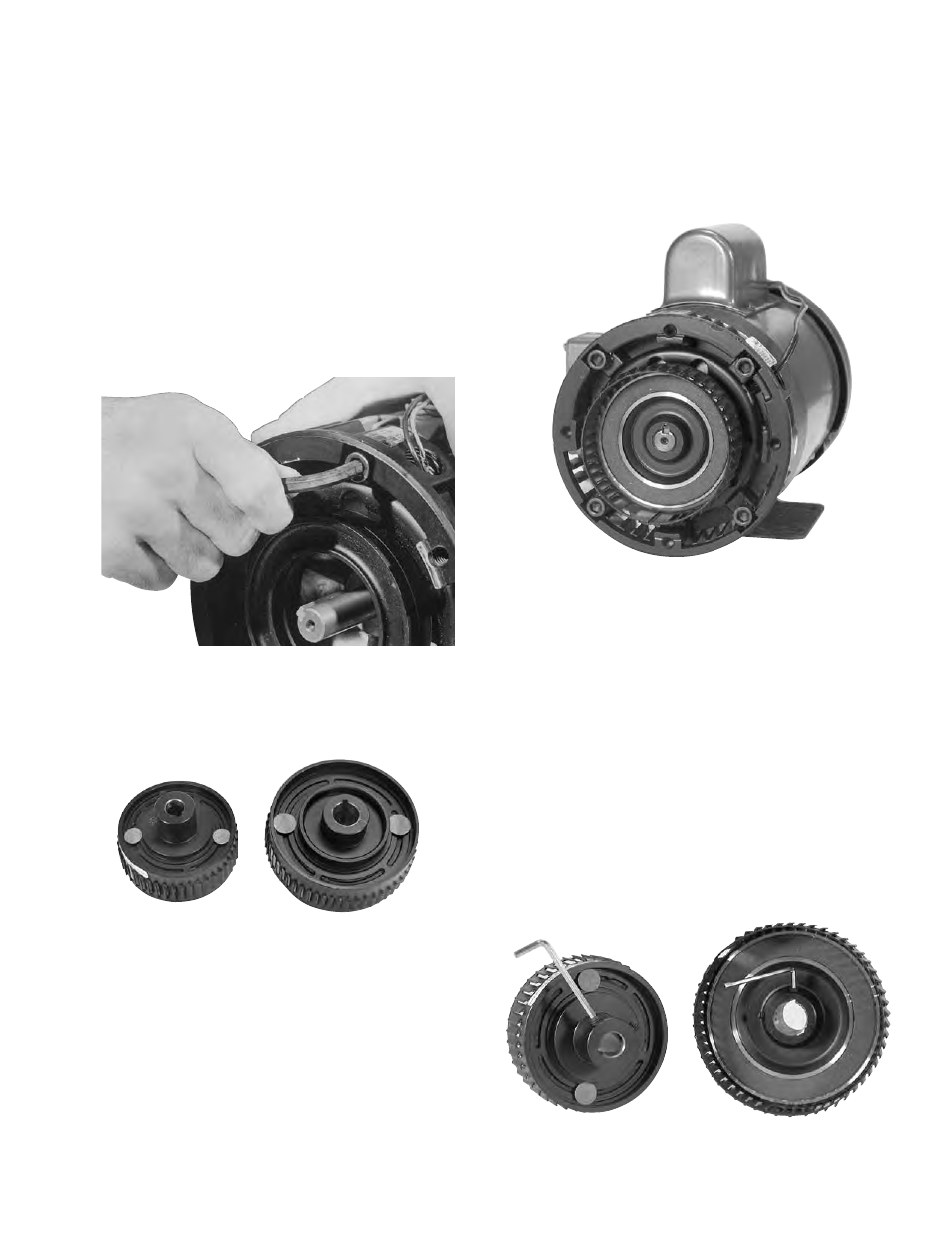

1. Examine the clutch adapter. Note that there

are gaps between the housing fins on roughly

half of the circumference of the unit. Mount

the clutch adapter with the open gaps down.

This will keep contaminants from falling into

the unit. There are four screws and washers.

These will be bolted through the adapter onto

the four holes in the face of the motor (See

Figure 1).

Figure 1

2. Look at the back side of the rotor and note

there are cardboard spacer buttons as

depicted in figure 2.

Figure 2

3. Slide the rotor onto the motor shaft. (See

Figure 3) Make sure the rotor hub slides

easily onto the shaft. If the fit is too tight,

polish the shaft with emery paper so the hub

will slide on easily. Do not use a hammer or

force the rotor hub onto the shaft. Slide the

rotor back off the shaft.

Figure 3

4. Insert key onto the shaft. Prick punch the

motor shaft keyway at the end of the key to

prevent the key from sliding out. Slide the

rotor onto the motor shaft until it bottoms

against the field.

5. Using an Allen Wrench securely tighten the

two setscrews in the rotor hub. (See Figure 4)

When the motor is turned on, the spacer but-

tons will quickly wear away and provide the

proper gap between the field and rotor. The

setscrews are accessible from the front of the

rotor on sizes 100, 180, 210, and from behind

the rotor on size 50 units.

Figure 4