Operation – general guidelines, Do not do this – Foredom Series L User Manual

Page 11

10

10

6. Diamond Burs:

Diamond Burs are used to remove stock from extremely hard materials such as tungsten and

tantalum carbide cutting tools, dies and molds, broaches, and for lapping and polishing synthetic

jewels and precious metals, fiberglass and reinforced plastics, PVC and ceramics.

7. CW Polishing Wheels: These longer-lasting rubber wheels impregnated with unique

ceramic abrasive grain are for finishing and polishing all hard and soft metals, precious

metals, and plastic. CW Wheels are available in 120 –1500 grit.

See the Accessory Catalog 350 or www.foredom.com for other accessories offered by

Foredom, i.e. Ruby Carvers, Tungsten Carbide Burs, Sanding Cartridge Rolls, etc.

Operation – General Guidelines

Minimum

Operating

Radius

4

″ radius

4″

ra

d

iu

s

Read all the safety instructions in this manual before operating your Foredom

®

Power Tool. Proper

eye and face protection must be worn to protect you from injuries caused by flying debris, chips, or

sparks which might result from the work being done.

Your Foredom motor may be operated in a vertical or horizontal position, but it should not

be enclosed or confined so as to restrict air circulation. If the motor is

hung up above a workbench, be sure it is fastened

securely to the wall or motor hanger. The motor may

develop a high operating temperature (up to 100

o

F +

ambient) after prolonged use, and it will be too hot to

hold. This will not harm the motor which is designed

to operate at this temperature for prolonged periods.

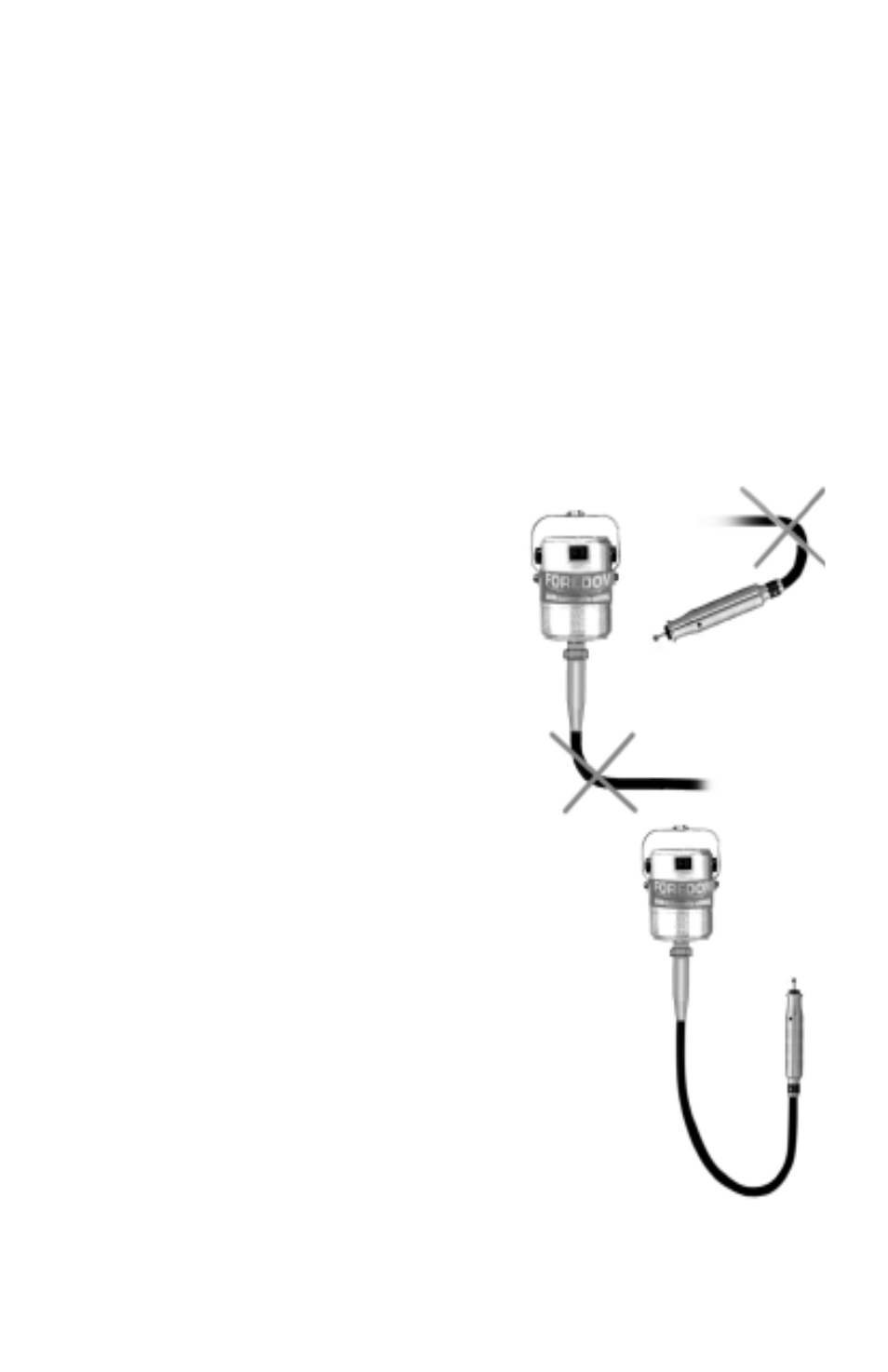

Do not bend at tight angle.

Shafts and sheaths last longer when they are used

without sharp bends. If used at angles or loops, wear

will occur at the points of greatest friction. When

operating your power tools be careful not to bend the

flexible shaft too much at either the handpiece or motor

shaft connections. Excessive heat and wear will occur if

the bend is too great.

Follow these guidelines for trouble-free use:

a 4

″or larger radius, as

shown below, should be maintained for shafts on all motors. In its

normal curved position All Foredom TX, CC, S, SR, and L Series

flexible shaft power tools can tolerate up to 12 lbs. of torque (the

Series TXH 1/3 horsepower can withstand 28 lbs. of torque before

breaking). There is no way to avoid ultimate wear and under normal

conditions a flexible shaft machine may require several replacement

shafts and sheaths during its lifetime. (Follow shaft and sheath

assembly instruction in the Assembly section of this manual.)

Do not force the tool

Let the speed of the tool do the work. Avoid using too much pressure.

Generally, slower speeds are used for rougher, heavier work or when

greater control over the accessory is required for precise, delicate work.

Higher speeds are used for buffing, cutting and polishing. Read Accessory

Recommendations on pages 8 and 9 of this manual.

Voltage Decreases

Never operate a power tool during a perceptible power decrease. Turn off tool and unplug

until full power is restored.

Do Not

Do This!