Securitron MCL-24 User Manual

Page 5

PN# 500-19100

Page 5

Rev. C, 04/11

4. Install Magnalock Body using four (4) #6 x 1” Long Pan Head Wood Screws (Item

#10). Tighten the screws firmly using a Phillips Head Screwdriver.

5. Run Power Cable to terminal connection as required.

6. OPERATIONAL INSTRUCTIONS

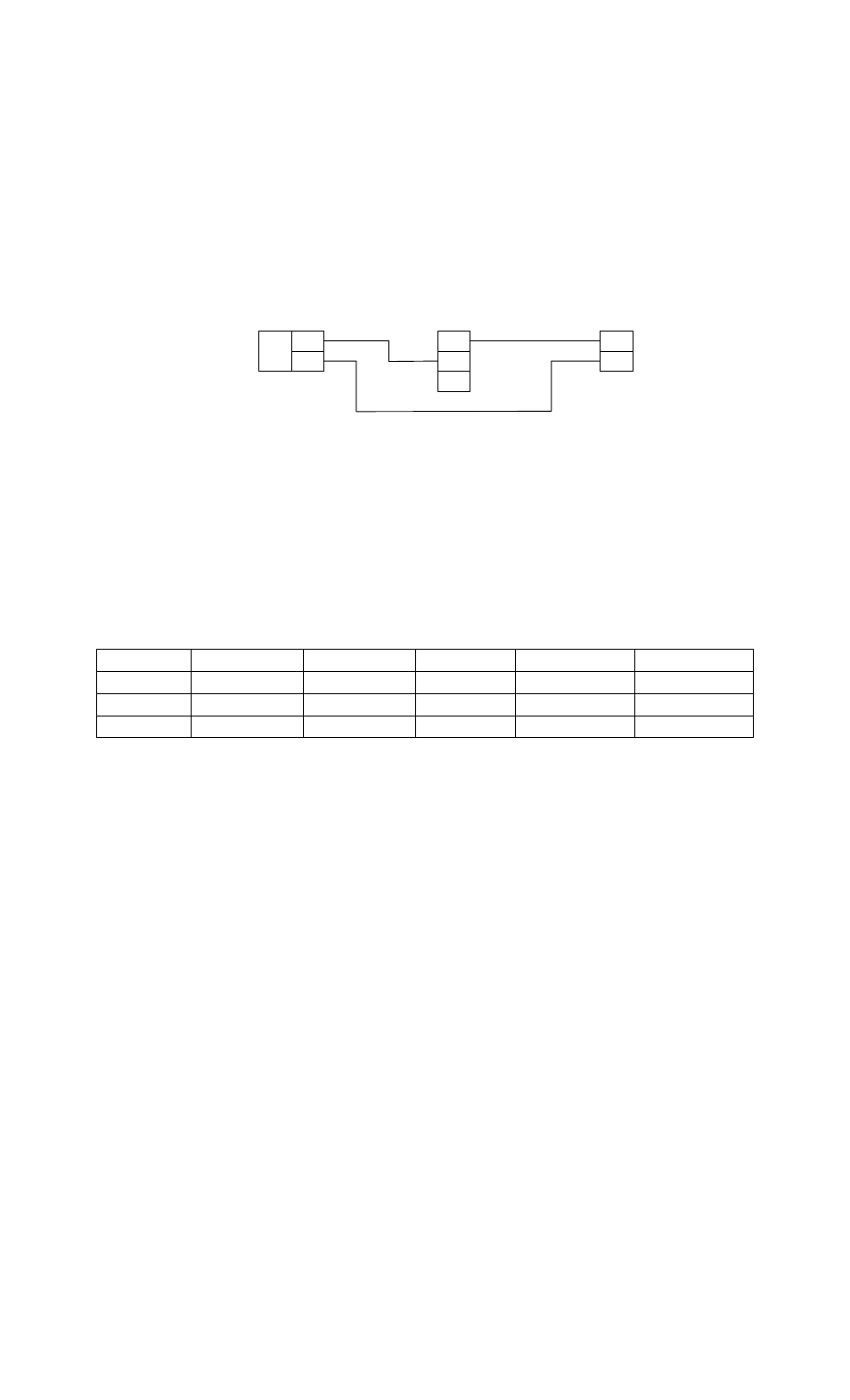

The Securitron Model MCL-24 is a Fail Safe locking device (power to lock). To power the MCL-24

you simply apply positive voltage DC to the red wire of the Magnalock through a normally closed

control switch. The black wire of the Magnalock should return directly to the negative DC.

Example

-

+

120

VAC

IN

VDC

OUT

POWER SUPPLY

NC

C

NO

SPDT

CONTROL

SWITCH

-

+

MCL-24

RED

BLK

6.1. WIRE GAUGE SIZING

If the power supply is distant from the lock, voltage will be lost (dropped) in the connecting

wires so that the Magnalock will not receive full voltage. The following chart shows the

minimum wire gauge that will hold voltage drop to an acceptable 5% for different lock to

power supply distances. Proper use of the chart assumes a dedicated pair of wires to power

each Magnalock (no common negative). Note that a Magnalock operating on 24 volts is a

much better choice for long wire runs as it has 4 times the resistance of a 12 volt installation.

Also note that the correct calculation of wire sizing is a very important issue as the installer is

responsible to insure that adequate voltage is supplied to any load. In multiple device

installations, the calculation can become quite complex so refer to Section 9 Appendix A for a

more complete discussion.

Distance Gauge

12V Gauge

24V Distance

Gauge 12V

Gauge 24V

80 FT

20 GA

24 GA

800 FT

10 GA

16 GA

200 FT

17 GA

22 GA

1500 FT

8 GA

14 GA

400 FT

14 GA

20 GA

3000 FT

N/A

12 GA

7. MAINTENANCE

Maintenance for MCL-24 is very simple. Once every six months we recommend taking a clean

cloth and rubbing alcohol or a non-abrasive cleaner and wiping down the face of the Magnalock

and the Armature. This prevents a build up of foreign materials from the air making the

Magnalock stick.

8. TROUBLESHOOTING

PROBLEM: No magnetic attraction between magnet and strike plate.

First be sure the Magnalock is being correctly powered with DC voltage. This includes

connecting the power wires with correct polarity. Positive must go to red and negative to

black. If the magnet body is wired in reverse polarity, it will not be damaged, but it will not

operate. If the unit continues to appear dead, it must be electrically checked with an

Ammeter. It must be powered with the correct input voltage and checked to see if it draws

the specified current. If the unit meters correctly, it is putting out the correct magnetic field

and the problem must lie in the mounting of the strike.

PROBLEM: The lock does not release.

When power is removed from it, the Magnalock must release. Therefore the complaint of

"lock will not release" is either mechanical bonding via vandalism or a failure to completely

release power. By mechanical bonding, we simply mean that glue has been applied between

the armature and magnet as a prank. Failure to completely release power is generally a

wiring integrity problem. What happens is that an upstream switch removes power from the

wires going to the Magnalock, but through an installation error, the wires have their

insulation abraded between the switch and lock so that partial or full power can leak in from

another Magnalock or other DC device with similarly abraded wiring. This is most likely to