Securitron M68 (L, S and LS with D and T Options) User Manual

Page 11

PN#

500-21400

Page

11

Rev. B, 8/07

8. APPENDICES

A.

WIRE GAUGE SIZING

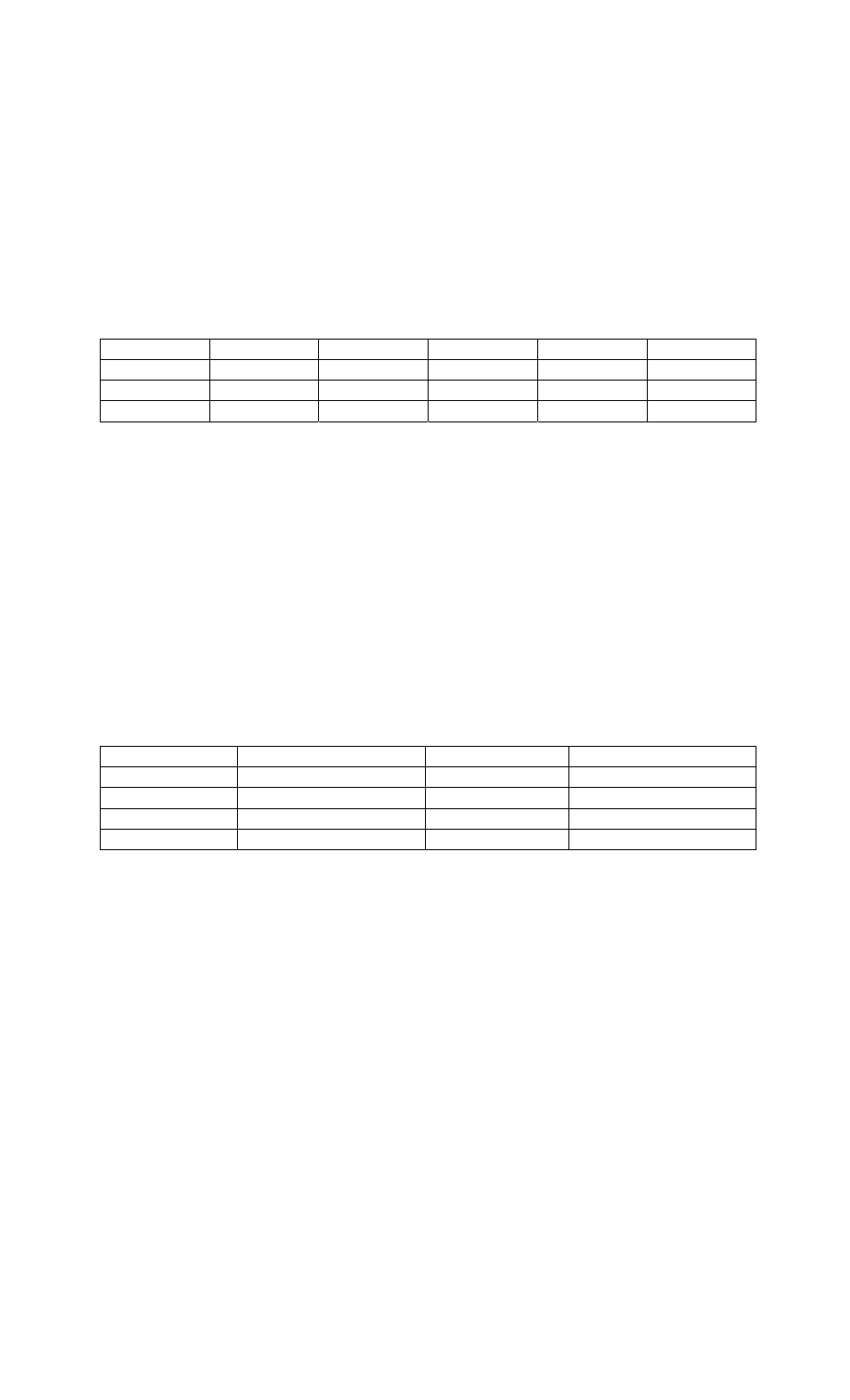

If the power supply is distant from the lock, voltage will be lost (dropped) in the connecting

wires so that the Magnalock will not receive full voltage. The following chart shows the

minimum wire gauge that will hold voltage drop to an acceptable 5% for different lock to

power supply distances. Proper use of the chart assumes a dedicated pair of wires to power

each Magnalock (no common negative). Note that a Magnalock operating on 24 volts is a

much better choice for long wire runs as it has 4 times the resistance of a 12 volt installation.

Also note that the correct calculation of wire sizing is a very important issue as the installer is

responsible to insure that adequate voltage is supplied to any load. In multiple device

installations, the calculation can become quite complex so refer to the following section

“Calculating Wire Gauge Sizing” for a more complete discussion.

Distance

Gauge 12V Gauge 24V

Distance Gauge

12V

Gauge

24V

100 FT

24 GA

24 GA

800 FT

18 GA

22 GA

200 FT

22 GA

24 GA

1500 FT

14 GA

18 GA

400 FT

20 GA

22 GA

2000 FT

14 GA

18 GA

CALCULATING WIRE GAUGE SIZING

The general practice of wire sizing in a DC circuit is to avoid causing voltage drops in

connecting wires that reduce the voltage available to operate the device. As Magnalocks are

very low power devices, they can be operated long distances from their power source. For any

job that includes long wire runs, the installer must be able to calculate the correct gauge of

wire to avoid excessive voltage drops.

This is done by taking the current draw of the lock and multiplying by the resistance of the

wire I x R = Voltage drop (i.e. 0.100A x 10.1 Ohms = 1.01 Volts dropped across the wire). For

all intents and purposes it can be said that a 5% drop in voltage is acceptable so if this were a

24 Volt system (24 Volts x .05 = 1.2 Volts) a 1.01 Volt drop would be within tolerance.

To calculate the wire resistance, you need to know the distance from the power supply to the

Magnalock and the gauge (thickness) of the wire. The following chart shows wire resistance

per 1000 ft (305 meters):

Wire Gauge

Resistance/1,000 ft

Wire Gauge

Resistance/1,000 ft

8 Gauge

.6 Ohms

16 Gauge

4.1 Ohms

10 Gauge

1.0 Ohms

18 Gauge

6.4 Ohms

12 Gauge

1.6 Ohms

20 Gauge

10.1 Ohms

14 Gauge

2.5 Ohms

22 Gauge

16.0 Ohms

B.

CONSIDERATIONS FOR MAXIMUM PHYSICAL SECURITY

M38 and M68 Magnalocks carry rated holding forces of 600 lbs. [272 Kg] and 1,200 lbs. [544

Kg] respectively. There are several installation and application variables to be considered

which affect the security level that may be obtained while using a Magnalock.

In the case of wooden doors (other than solid hardwoods), aluminum frame glass doors, and

hollow metal doors, the M38 should be employed in a “traffic control” mode. This is because a

determined assault on these types of door/lock configurations has the potential of “popping”

this model open. The M68 is generally stronger that the door itself. Users have logged

periodic cases of an assault where the door has been destroyed leaving the Magnalock intact

and still retaining the piece of the door where the strike was mounted.

A pry bar may be used to try to pry the door open. However, what generally occurs is that the

door will experience material failure. The pry bar tears (in the case of wood) or bends (metal)

the door material without defeating the lock. The general fact that a Magnalock mounts on the

other side of the door from the attacker is an important contributor to its strong resistance to

assault.

The concept of preferring a door that gives also affects the issue of physical security on

different door types. Oddly enough, the characteristics that make an inswinging door strong