Ransburg, Troubleshooting guide, Vector r series cascade applicators - maintenance – Ransburg Vector R Series Cascade 79523 R90 Waterborne User Manual

Page 53

Vector R Series Cascade Applicators - Maintenance

Ransburg

49

Replace fluid nozzle.

Replace.

Tighten.

Adjust (see “Trigger Adjustment Nut

Dimension Figure” in the “Maintenance”

section).

Trace and correct (1 megohm maxi-

mum ground to target resistance).

See Ransburg “Applicator Spray

Techniques” manual.

Trace and correct.

Reduce pressure.

Decrease distance between applicator

and target.

Check and secure at the applicator and

at the control unit.

Trace and correct.

Replace.

Replace.

Replace.

Clean as required per suggested

“Maintenance Schedule”.

(Continued On Next Page)

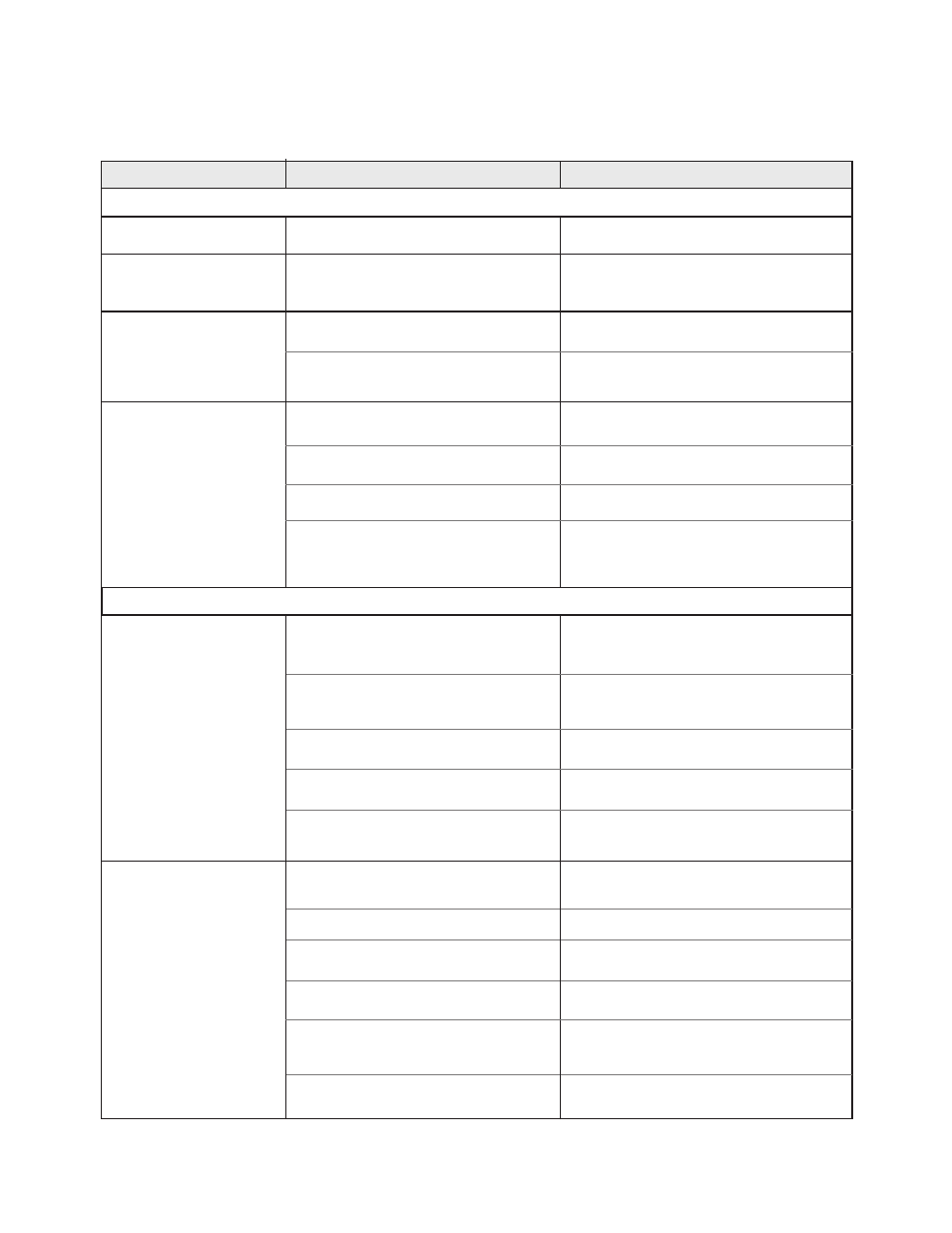

TROUBLESHOOTING GUIDE

(Cont.)

General Problem

Possible Cause

Solution

ELECTRICAL

Air

Defective valve seat or valve spring

See “Barrel Assembly” in the

“Maintenance” section.

Clean and lubricate or replace.

Cartridge seal assembly and/or

needle/electrode shaft defective

Fluid

(At rear of barrel)

Fluid

(Slight leak at nozzle

when trigger is

released)

Nozzle not secure

Air valve closing before fluid valve

Tighten.

Adjust needle shaft/electrode travel.

Fluid

(Constant at nozzle)

Worn or damaged fluid nozzle

Worn or damaged needle/electrode

Loose fluid nozzle

Needle/electrode does not seat when

trigger is released

Wrap Back

Improper target ground

Improper spray technique

Improper booth exhaust

Excessive atomizing air

Excessive target distance

Improper or No

High Voltage

Is the power turned on?

Is the atomizing air turned on?

Is the applicator triggered?

Blown fuse

Faulty high voltage cable

connections

Is the paint too conductive?

LEAKAGE

AH-06-01.13