Ransburg, Applicator assembly cleaning procedure – Ransburg Vector R Series Cascade 79523 R90 Waterborne User Manual

Page 37

Vector R Series Cascade Applicators - Maintenance

Ransburg

33

If production downtime is to be short,

the fluid lines may not require flushing,

depending on the coating material being

used. If the solids in the material settle

slowly, the lines will not need to be flushed

as soon after shutdown as with fast set-

tling solids. The paint being used and the

length of downtime will determine the need

for flushing. Metallic paint and primer will

require flushing sooner than other types of

coating materials.

NOTE

2. Trigger the applicator (high voltage ON).

3. Slowly approach the applicator electrode to

any grounded object and make contact.

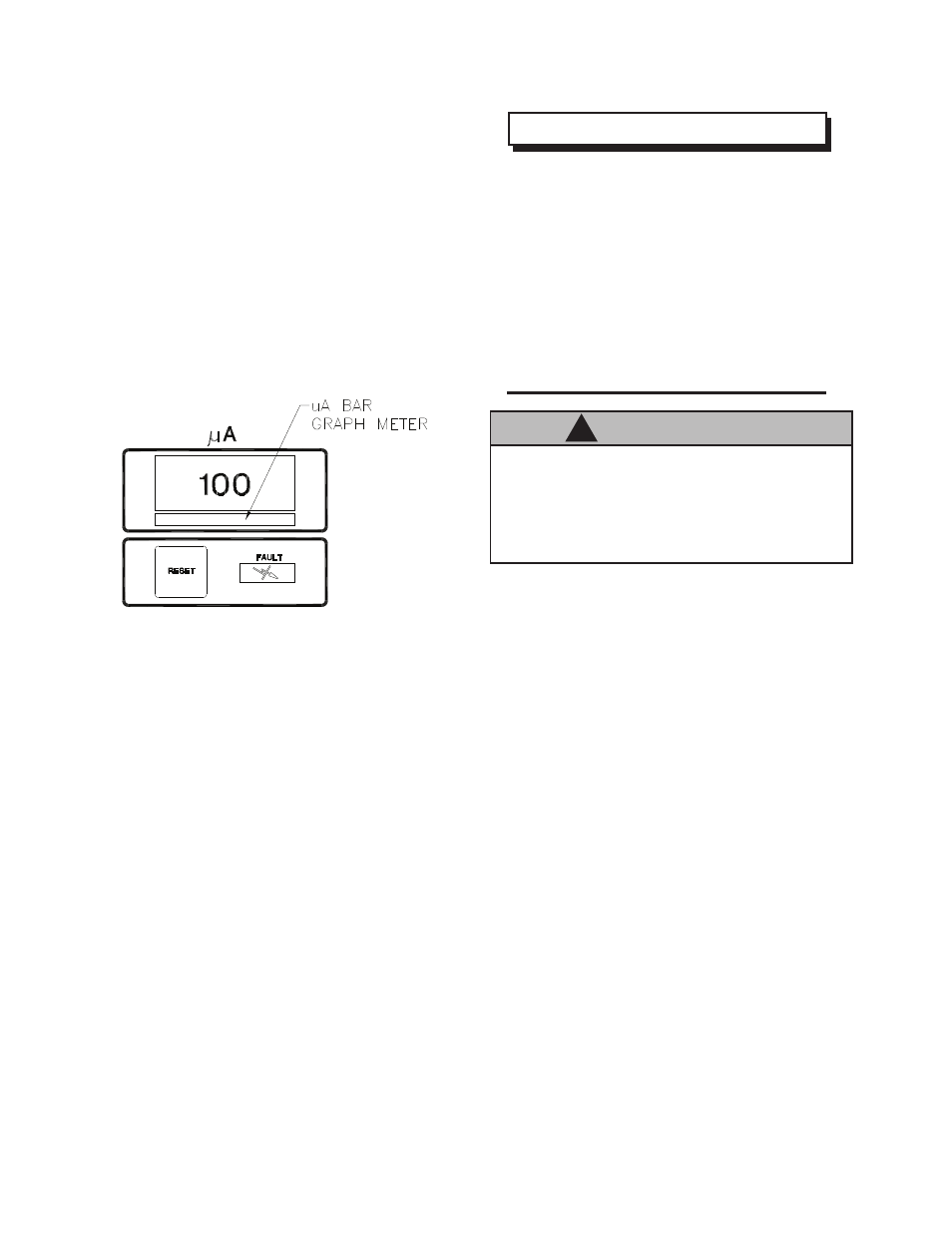

4. Monitor the current output reading on the

control unit microamp meter as the applicator

approaches ground:

Upon ground contact, the microamp meter should

display 100 µA (for R90) or 90 µA (for R70) and

the green, yellow, and red LED's of the bar graph

meter will all be illuminated.

If the coating material is fast settling

and the fluid lines are not flushed soon

enough, the internal passages may be-

come clogged. This can lead to excessive

downtime for repair.

C A U T I O N

!

Figure 16: Control Unit Meter Current Output

Test Reading

If the reading is outside of the acceptable range

(95-100 µA for R90; 85-90 µA for R70), DO NOT

use the applicator until the problem has been

corrected (see "Troubleshooting Guide" in the

"Maintenance" section.)

5. Release the trigger (high voltage OFF) and

turn the control unit power OFF.

Shutdown (or at end of each shift)

1. Turn the power supply power OFF.

2. Turn the paint supply OFF.

3. Turn the atomizing and fan air OFF.

4. Wipe the applicator, cable, and hoses with a

rag and a suitable cleaning solvent.

5. Flush the lines and allow the solvent to remain

in the lines unpressured (see "Flushing Proce-du-

res" in the "Maintenance" section).

Weekly

• Check the entire system for damage, leaks,

and paint accumulation.

• Clean the atomizer assembly.

APPLICATOR ASSEMBLY

CLEANING PROCEDURE

Routine Cleaning Equipment

Needed

• An appropriate solvent

• A solvent safety container (grounded)

• A small soft-bristled brush

• The Ransburg special multi-purpose

wrench (19749-00)

AH-06-01.13