Ransburg, Needle / electrode – Ransburg Vector R Series Cascade 79523 R90 Waterborne User Manual

Page 42

Vector R Series Cascade Applicators - Maintenance

Ransburg

38

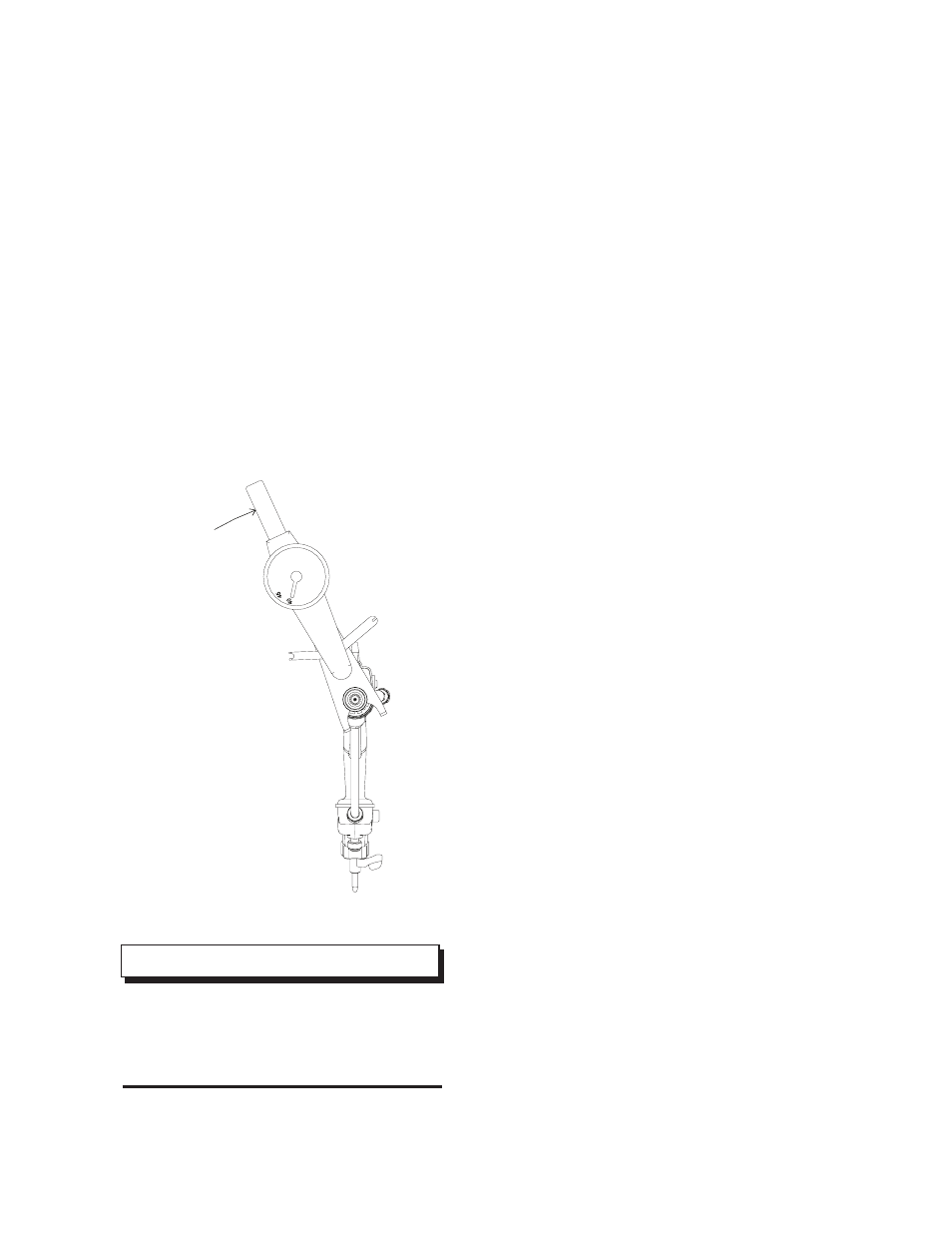

Reinstall

1. Check the needle/electrode tightness on the

needle shaft. If it is loose, tighten it (refer to "Nee-

dle/Electrode" in the "Maintenance" section).

2. With the applicator trigger actuated, place the

fluid nozzle over the needle/electrode and screw

it into the barrel by hand.

3. Tighten it using the special multi-purpose

wrench with 3/8" square. Torque to 40-45 lbs - in

(4.5-5.1 Nm). An alternate method (if no torque

wrench is available) is to hand tighten, then tight-

en an additional 1/16 to 1/8 turn in the clockwise

direction.

4. Install the air cap and retaining ring onto the

applicator (refer to "Air Cap - Reinstall" in the

"Maintenance" section).

Figure 20: Reinstalling Fluid Nozzle

DO NOT over-tighten the fluid nozzle

into the barrel. Doing so could damage

or break the fluid nozzle or damage the

thread of the barrel.

NOTE

NEEDLE / ELECTRODE

Removal

1. Remove the air cap and fluid nozzle from the

applicator assembly.

2. Secure the needle shaft at the rear of the barrel

and unscrew the needle/electrode from the needle

shaft.

Cleaning and Inspection

1. Use a suitable solvent to clean the needle/

electrode.

2. Examine the needle/electrode for damage or

wear. Pay special attention to the area where

the wire electrode extends from the main body.

This is a sealing surface that seats inside the fluid

nozzle. If there are signs of wear in this area,

both the needle/electrode and fluid nozzle must

be replaced.

3. An electrical check of the needle/electrode must

be done prior to reinstalling it into the applicator

assembly (refer to "Needle/Electrode Resistance

Testing" in the "Maintenance" section).

Reinstall

1. Secure the needle shaft at the rear of the barrel

and screw the needle/electrode into place by hand.

2. Reinstall the fluid nozzle and air cap onto the

barrel.

C W

3 5 -4 0

L B S -I N

3 . 9 -4 . 5 N M

AH-06-01.13