Teledyne BDS-3000 - Oxygen analyzer User Manual

Page 28

Operational Theory

BDS 3000

Teledyne Analytical Instruments

14

water) inside the sensor is gradually concentrated during the sensor

operation. It typically takes about four months for the electrolyte level to

drop from the Max line to Min line. When adding water to increase the

electrolyte level from the Min line to the Max line, it is typical that the

oxygen reading will drift down about 10 ppb in an hour. If the oxygen

content in the sample gas is very close to zero, the analyzer may display

a negative reading during this period. The sensor will recover by itself

during the following week. This drift-down then recover-back

phenomenon is caused by the quick dilution of the electrolyte and re-

establishment of a new equilibrium inside the sensor. To minimize this

effect, add a small amount of water each time and do this before the

electrolyte level reaches the Min line.

2.3

Sample System

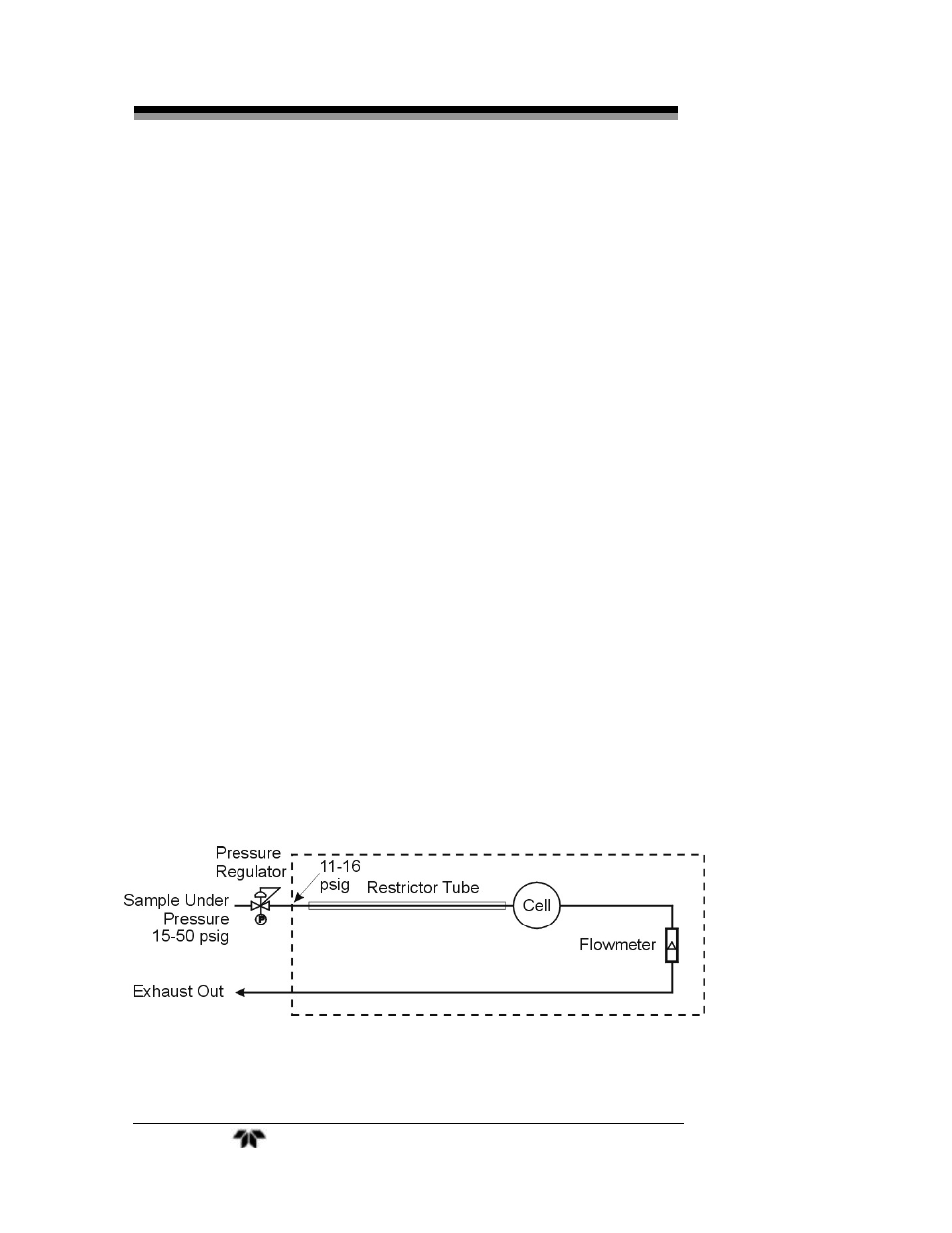

The sample system delivers gases to the BDS sensor from the

analyzer rear panel inlet. Depending on the mode of operation either

sample or calibration gas is delivered.

The Model BDS 3000 sample system is designed and fabricated to

ensure that the oxygen concentration of the gas is not altered as it travels

through the sample system.

The sampl e syst em for the standar d inst rument incor porates 1/4" VCR

fit tings for sample inl et and swagelock fittings for outl et tube connections at

the rear panel. The sample or cal ibrati on gas that flows through the system

is monitored by a flowmeter downstream from the sensor .

Figure 2-6 represents the flow diagram of the sampling system. In

the standard instrument, calibration gases can be connected directly to

the Sample In port by teeing to the port with appropriate valves.

Figure 2-6: Flow Diagram