Sintered wire: turn when commencing work, Progressed work, example: 10 m, sintered, Galvanic wire: turn when commencing work – Diamond Products SK-B User Manual

Page 39: Progressed work, example: 10 m, galvanic

Wire sawing system

6.%

7KH GLDPRQG ZLUH

SK-B_0008_e.mif

page 39

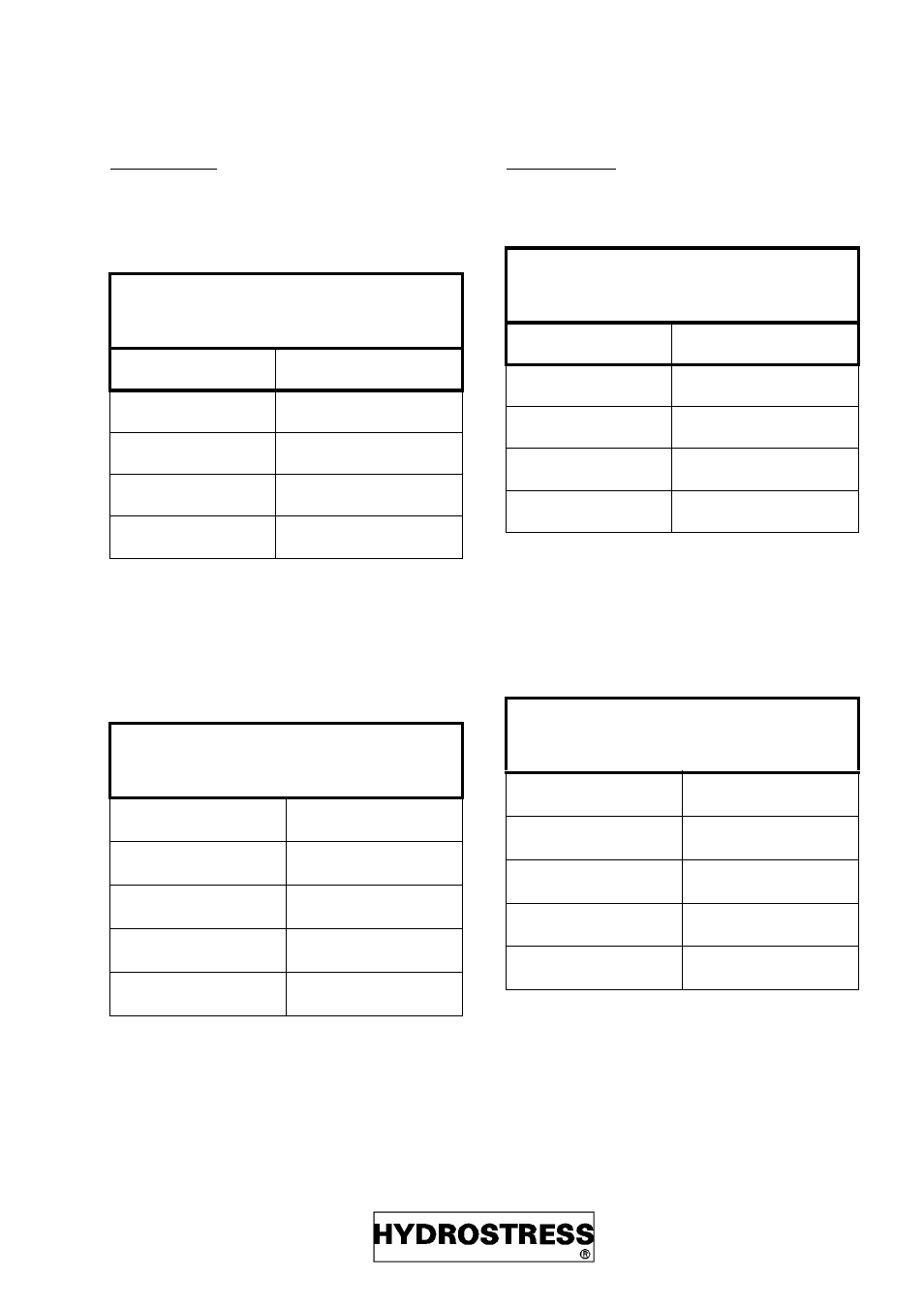

Sintered wire

A sintered wire must be turned at least once

per metre in an anti-clockwise direction when

first used.

In order to ensure regular wear of the wire

beads, frequently change the turn of the wire

by approximately + or -30%, however, never

less than once per metre of wire. The turn

should be changed after each cut.

Galvanic wire

A galvanic wire must be turned anti-clockwise

0.5 - 1.5 times per metre when first used.

In order to ensure regular wear on the wire

beads, frequently change the turn of the wire,

however never less than once and never more

than 1.5 times per metre of wire.

The turn should be changed after each cut.

When flattening starts change the number of

turns as much as possible, e.g. 2 to 4 or even

more.

Sintered wire: Turn when

commencing work

.GPIVJ QH VJG YKTG

6QVCN VWTPU

PHWUHV

WXUQ WLPHV

PHWUHV

WXUQ WLPHV

PHWUHV

WXUQ WLPHV

PHWUHV

WXUQ WLPHV

Progressed work,

Example: 10 m, sintered

DIWHU VW FXW

turn + 3 times

DIWHU QG FXW

turn + 3 times

DIWHU UG FXW

release 3 times

DIWHU WK FXW

turn + 3 times

DIWHU WK FXW

release 3 times, etc.

Galvanic wire: Turn when

commencing work

.GPIVJ QH VJG YKTG

6QVCN VWTPU

PHWUHV

WXUQV

PHWUHV

WXUQV

PHWUHV

WXUQV

PHWUHV

WXUQV

Progressed work,

Example: 10 m, galvanic

DIWHU VW FXW

turn + 3 times

DIWHU QG FXW

turn + 3 times

DIWHU UG FXW

release 3 times

DIWHU WK FXW

turn + 3 times

DIWHU WK FXW

release 3 times, etc.