Controlled Products Systems Group 9210-081 User Manual

Page 38

9210-065-F-4-12

36

7.1 Maintenance

SECTION 7 - MAINTENANCE AND TROUBLESHOOTING

Inspection and service of this gate operator by a qualified technician should be performed anytime a malfunction is observed or

suspected. High cycle usage may require more frequent service checks.

When servicing the gate operator, always check any secondary (external) reversing devices (loops, photocells, etc.) for proper

operation. If external reversing devices cannot be made operable, do not place this operator in service until the malfunction can

be identified and corrected.

Always check the inherent reversing system when performing any maintenance. If the inherent reversing system cannot be

made operable, remove this operator from service until the cause of the malfunction is identified and corrected. Keeping

this operator in service when the inherent reversing system is malfunctioning creates a hazard for persons which can result

in serious injury or death should they become entrapped in the gate.

When servicing this gate operator, always turn power OFF!!

If gearbox requires oil, use only Mobil SHC-629 Synthetic Gear Oil. Do not completely fill gearbox with oil. Gearbox

should be half full only. Do not exceed this level.

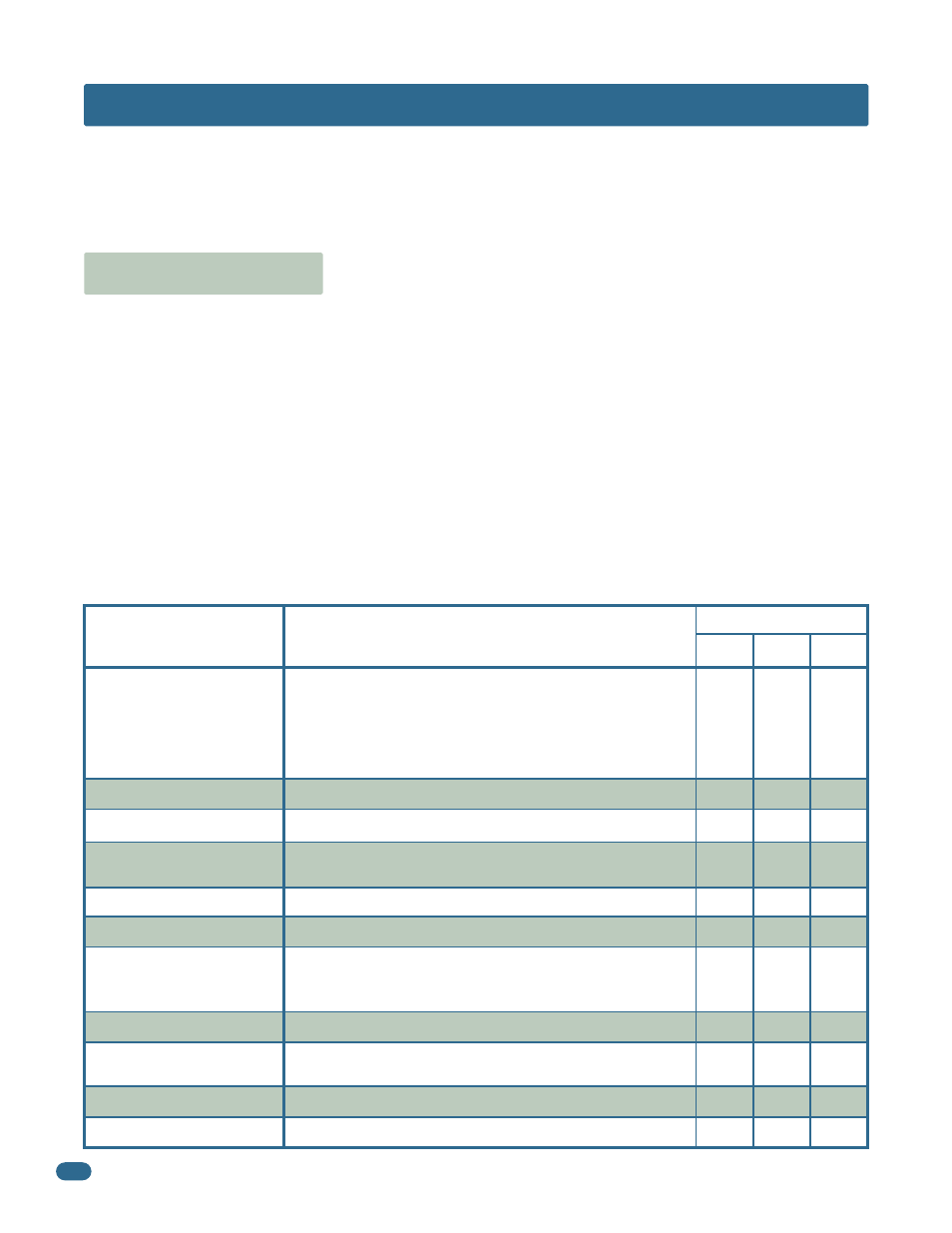

Operator

Component

Maintenance

Monthly Interval

6

3 12

Alarm

Chain

✓

✓

✓

✓

✓

✓

✓

✓

✓

Fire Dept.

Gate

Loop(s)

Release

Primary Reverse System

Secondary Reverse Device

Complete System

Activate the primary (inherent) reverse system by blocking the

gate with a solid object. When the gate reverses, block the gate

in the opposite direction prior to the limit being reached. The

entrapment alarm should activate. Press the reset button to

silence the alarm.

Check for sagging. Tighten if necessary.

Check vehicular exit and reverse loops for proper operation.

Check manual release for proper operation.

Complete check of gate and gate operating system.

Check emergency vehicle access device for proper operation.

Grease

Wheels and guide rollers if necessary.

Inspect for damage. Check gate wheels. rollers and guides for

wear and grease if necessary.

Check that the gate reverses on contact with an object in both

the opening and closing cycles.

Adjust the reversing sensor if necessary.

Check secondary (external) reverse device(s) stop or reverse the

gate when activated.

Sprockets

Check set screws for tightness.

✓

✓