3 manual gate operation, Unlock manual crank access panel, Caution – Controlled Products Systems Group 9210-081 User Manual

Page 37

9210-065-F-4-12

35

WA

RN

ING

MO

VIN

G G

ATE

CA

N C

AU

SE

Op

era

te g

ate

on

ly wh

en g

ate

are

a is

in s

igh

t

and

fre

e o

f p

eop

le a

nd o

bstr

ucti

ons

.

Do

no

t allo

w c

hild

ren

to p

lay

in

ga

te a

rea

or o

per

ate

ga

te.

Do

no

t sta

nd i

n g

ate

pa

th o

r wa

lk t

hro

ugh

path

wh

ile

ga

te i

s m

ovin

g.

Rea

d o

wn

er’s

m

anu

al a

nd s

afe

ty in

stru

ctio

ns.

SE

RIO

US

INJ

UR

Y O

R D

EAT

H

CLA

SS

CER

TIF

IED

TO

CA

N/

CS

A C

22

.2 NO.

247

CONFOR

MS

TO

ANS

I/U

L-

325

VEHI

CU

LA

R G

AT

E OP

ERA

TOR

HP

53

382

MODE

L

SERI

AL

VOL

TS

PH

AS

E

AM

PS

60

Hz

MA

X GA

TE

LOA

D

Doo

rKin

g,

Inc

.,

Ing

lewo

od,

CA

EXIT

LOOP

LMT

REVERSE

LOOP

REV SENSE

CLOSE

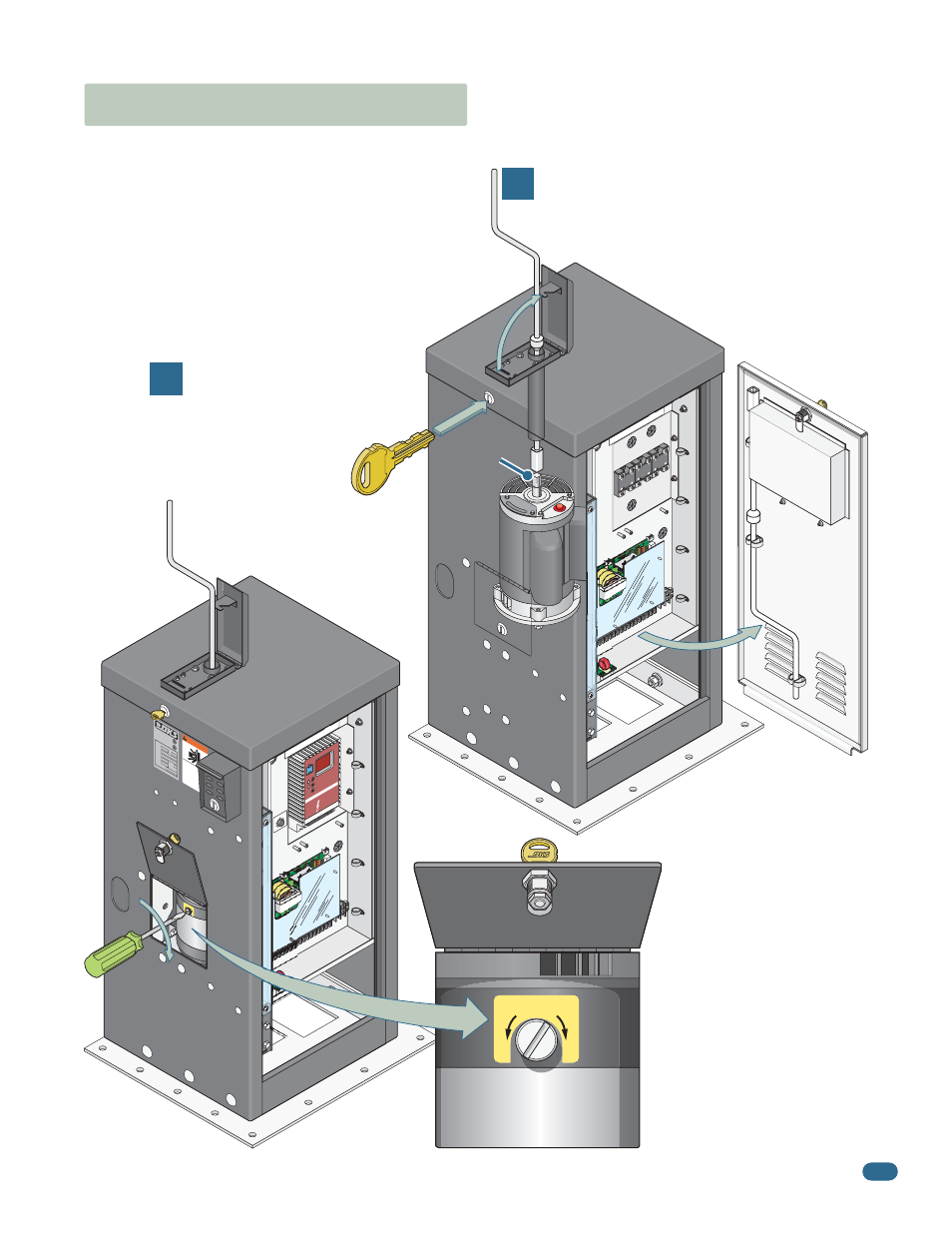

6.3 Manual Gate Operation

Caution:

Never attempt to manually operate any gate until you have verified that power to the operator has been shut-off.

Unlock Manual Crank

Access Panel

Cuts off AC power to the operator.

Manual Crank

9235, 9245

Mechanical Disc

Brake

The disc brake MUST be manually

released (disengaged) with a slotted

screwdriver (Not provided) before

manually operating the gate.

Disc brake will automatically

reengage after power has been

restored.

R E S E T

EXIT

LOOP

LMT

REVERSE

LOOP

REV SENSE

CLOSE

1

2

4

3

1

2

4

3

1

2

4

3

Manual Crank

Access Panel

Insert the supplied manual hand crank into the

access hole until it engages with the motor shaft.

Turn the crank to open the gate. 9235, 9245

mechanical disc brake model operators

MUST also have the disc brake

manually released before

manually cranking the

hand crank (See

below).

Motor

Shaft

Manual

crank in

stored

position.

Turn manual release

1/4 turn clockwise

to release the

disc brake.

MANUAL

RELEASE

R

E

S

E

T

R

E

L

E

A

S

E

MA

NUAL

REL

EAS

E

R

E

S

E

T

R

E

L

E

A

S

E

1

2

1

2

5

6

11

13A

13B

13E

25

16

17

L1

L2

L3

B-

B+

M

od

e

EPM

0 0 0

SCM

ser

ies

basi

c I/O

control

1 ft/s

.5

ft/s

0 ft/s

2 ft/s

1.5

ft/s

Disc

Brake

Access

Panel