7 installation of warning signs, 1 high voltage wire runs, This gate operator must be properly grounded – Controlled Products Systems Group 9210-081 User Manual

Page 19: Typical grounding sources, Wire size / distance in feet

9210-065-F-4-12

17

1.7 Installation of Warning Signs

This DoorKing Slide Gate Operator is shipped with two warning signs. The purpose

of the warning sign is to alert uninformed persons, and to remind persons familiar

with the gate system, that a possible hazard exists so that appropriate action can

be taken to avoid the hazard or to reduce exposure to the hazard. See page 9 for

typical placement of signs.

•

Permanently install the supplied warning signs in locations so

that the signs are visible by persons on both sides of the gate.

•

Use appropriate hardware such as wood or sheet metal screws

(not supplied) to install the warning signs.

2.1 High Voltage Wire Runs

The 9200 draws significant power and each operator should have a “Dedicated” circuit breaker at the power source. If power wiring is

greater than the maximum distance shown, it is recommended that a service feeder be installed. When large gauge wire is used, a separate

junction box must be installed for the operator connection. The wire table is based on stranded copper wire. Wire run calculations are based

on the NEC recommended maximum 3% voltage drop on the power line, plus an additional 10% reduction in distance to allow for other losses

in the system.

Wire Size / Distance in Feet

Amps

12 AWG

10 AWG

8 AWG

6 AWG

9210 Single 1 HP: 115 VAC

9210 Single 1 HP: 208 VAC

9210 Single 1 HP: 230 VAC

9220 Single 2 HP: 208 VAC

9220 Single 2 HP: 230 VAC

9245 Single 3 HP: 208 VAC

9245 Single 3 HP: 230 VAC

9210 Single 1 HP: 208 VAC

9210 Single 1 HP: 230 VAC

9220 Single 2 HP: 208 VAC

9220 Single 2 HP: 230 VAC

9230, 9240 Single 3 HP: 208 VAC

9230, 9240 Single 3 HP: 230 VAC

9235 Single 3 HP: 208 VAC

9235 Single 3 HP: 230 VAC

Single Phase

Three Phase

SECTION 2 - AC POWER TO OPERATOR(S)

Before attempting to connect any wiring to the operator, be sure that the circuit breaker in the electrical panel is in the OFF position. Perma-

nent wiring must be installed to the operator as required by local electrical codes. It is recommended that a licensed electrical contractor

perform this work.

Since building codes vary from city to city, we highly recommend that you check with your local building department prior to installing

any permanent wiring to be sure that all wiring to the operator (both high and low voltage) complies with local code requirements.

THIS GATE OPERATOR MUST BE PROPERLY GROUNDED!!

110

390

440

165

180

150

170

680

730

340

400

225

255

177

195

175

620

700

270

290

240

270

1090

1170

545

640

365

415

280

315

295

1040

1170

450

490

400

450

1815

1950

905

1070

610

690

465

525

440

1560

1760

675

735

600

680

2720

2920

1360

1605

915

1035

700

790

9.7

5.0

4.9

11.5

11.7

12.8

12.6

3.3

3.4

6.6

6.2

9.8

9.6

12.8

12.6

Never run low voltage rated wire insulation in the

same conduit as high voltage rated wire insulation.

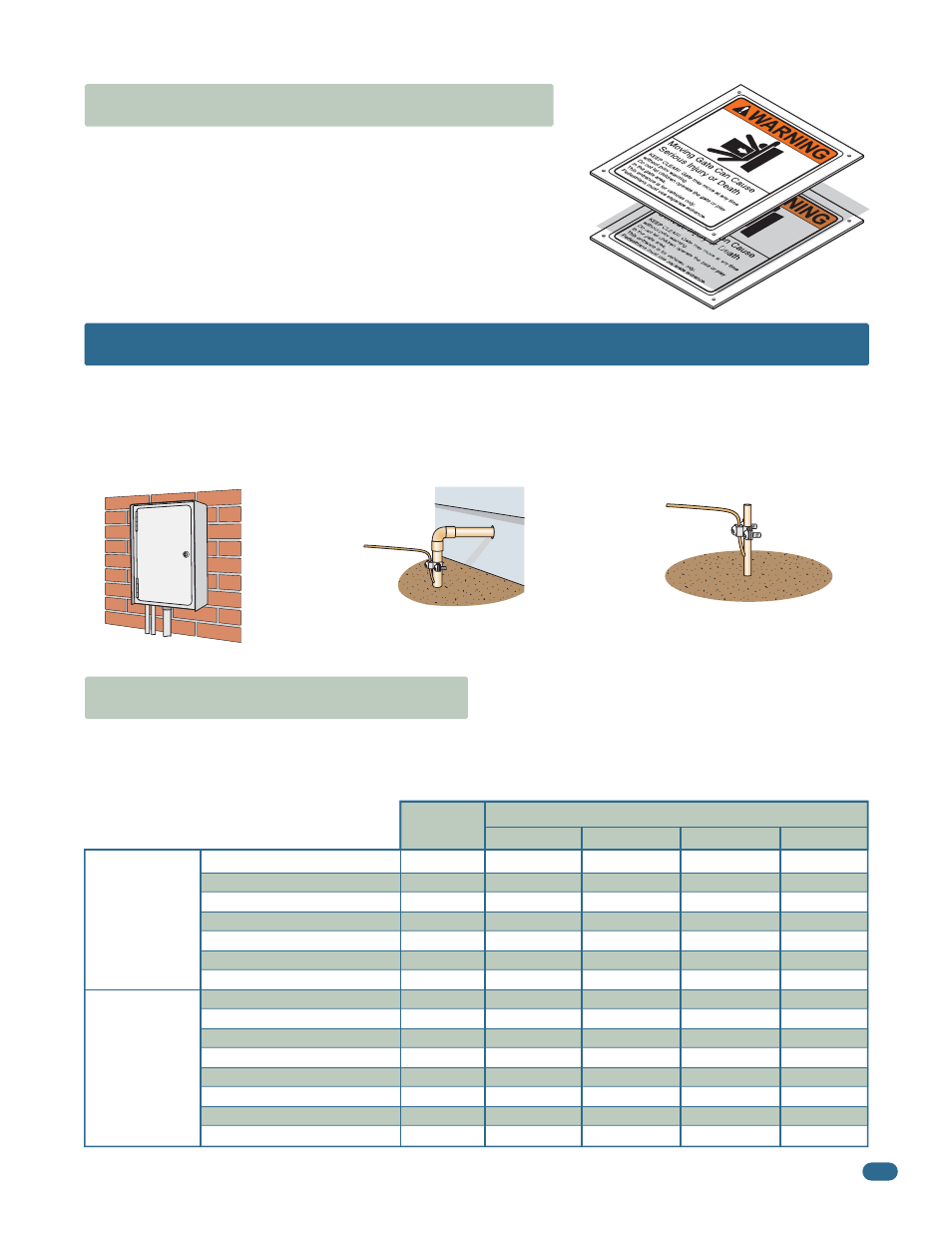

Typical Grounding Sources

Ground to metallic cold water pipe.

Ground

Wire

Ground

Wire

Ground to existing electrical system.

Electrical

Panel

Grounding rod 10 feet in soil.

IMPORTANT:

Ground wire shown without

safety protection for clarity. Make sure

ground wire is protected from being

touched or electrical shock could occur!