5 clutch adjustment, 6 inherent entrapment protection system, Test the clutch – Controlled Products Systems Group 6300-080 User Manual

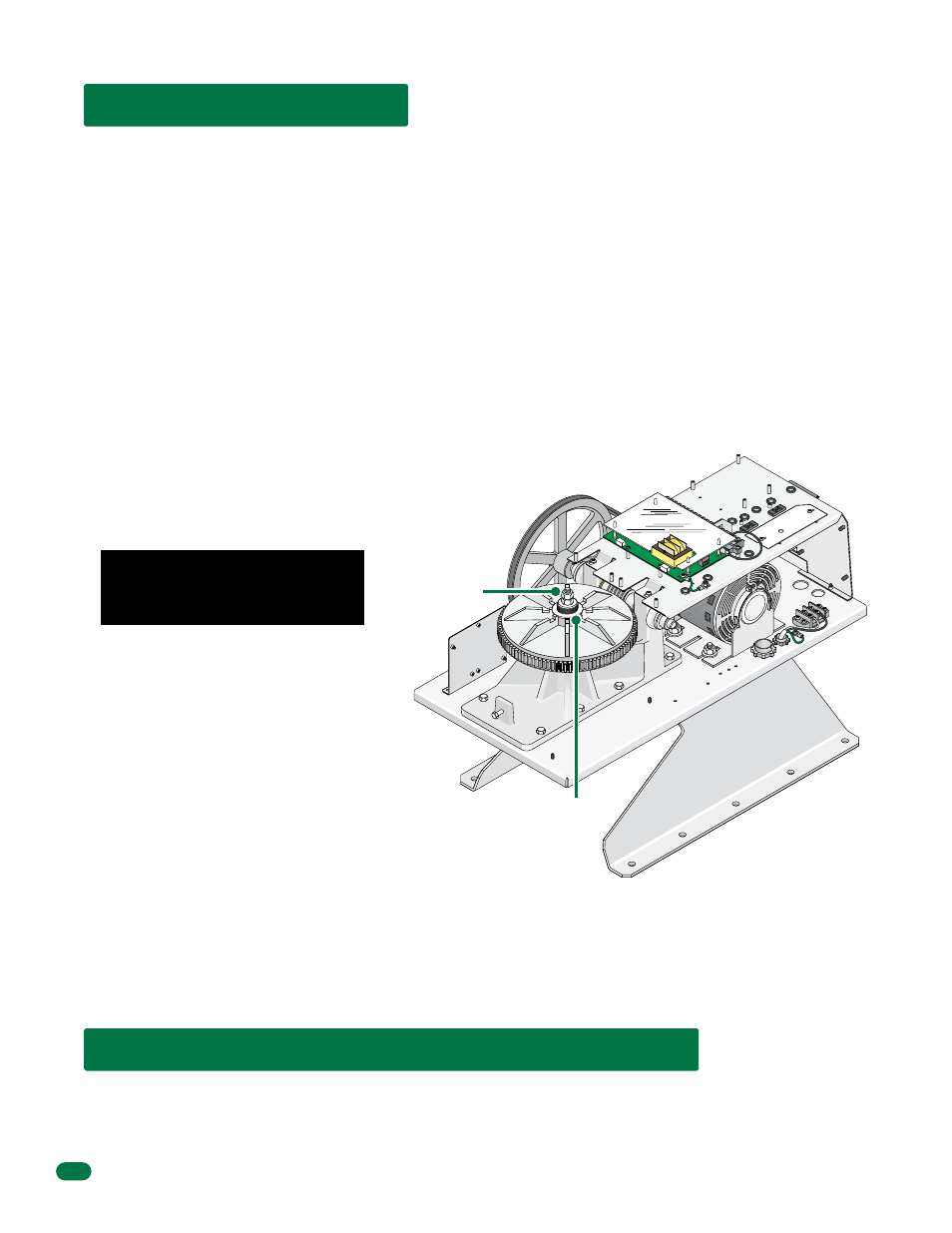

Page 24: Jamb nuts clutch

6300-065-Z-7-12

22

3.5 Clutch Adjustment

This vehicular gate operator is equipped with an inherent adjustable clutch (Type C) that is used as the Primary entrapment

protection system. The clutch MUST slip upon sensing an obstruction during the open or close cycle which will cause the gate

to reverse direction. For this system to function correctly, the gate must be properly installed and work freely in both directions.

A good set of roller bearing hinges is essential for proper swing gate operation.

In addition to the mechanical slip clutch, this operator uses an inherent entrapment protection system (Type A) to further

reduce the possibility of injury should an entrapment occur. This Secondary entrapment protection system (Revering sensor) is

completely automatic and will be activated if the clutch fails to slip when an obstruction is sensed during the open or close

cycle. This feature requires no adjustment by the installer or end user.

3.6 Inherent Entrapment Protection System

Test the Clutch:

Obstruct the gate while it is in the

OPENING cycle.

The clutch MUST slip with no more than 40 Lbs of

force, then the gate will reverse direction for a

quarter of a second and STOP. If the clutch does not

slip, it is too tight. Repeat step 4 and re-adjust the

clutch.

Note: After the gate has reversed and STOPPED, the

operator will be in a “Soft Shutdown”. Momentarily

jump across terminals 11 and 20 to continue the

opening cycle after the obstruction has been

cleared.

Obstruct the gate while it is in the

CLOSING cycle.

The clutch MUST slip with no more than 40 Lbs of force, then the gate will REVERSE direction back to the open position.

If the clutch does not slip, it is too tight. Repeat step 4 and re-adjust the clutch.

Note: After the gate has reversed back to the open position, the operator will be in a “Soft Shutdown”. Momentarily jump

across terminals 11 and 20 to start the closing cycle again after the obstruction has been cleared.

1.

Be sure AC power switch is turned OFF whenever adjustments to the clutch are being made.

Loosen the

upper jamb nut to “un-lock” the lower jamb nut. Loosen the lower jamb nut.

2. Manually move the gate so that it is positioned approximately half way open.

3. Tighten the lower jamb nut finger tight then tighten it ONE turn with a wrench. Re-tighten the upper jamb nut.

4. Turn AC power switch ON and momentarily jump across terminals 11 and 20. When the gate begins to open,

determine if the clutch is slipping. If the clutch is slipping, turn AC power OFF and tighten the lower jamb nut

one more turn. This process may have to be repeated several times to get the clutch adjusted correctly.

Always start the gate from the half open position when adjusting the clutch.

Jamb Nuts

Clutch

Clutch Note: The ideal clutch adjustment will

allow the operator to move the gate through its

open and close travel cycle without slipping,

but will slip upon contact with an obstruction

with no more than 40 Lbs of force. This force

can be measured with a gate scale, DoorKing

P/N 2600-225.

CAUTION:

Keep pedestrians and

vehicles clear of the gate while

adjusting and testing the clutch!