CONTREX MLP-Trim User Manual

Page 84

3 - 44

Inverse Master Mode Example

The Inverse Master Mode Example demonstrates how scaling and setpoint Control

Parameters are entered for a typical Inverse Master mode of operation:

It takes 10 seconds to move a product through a heat treat oven when

the conveyor motor is running at 1500 RPM. The conveyor motor shaft

is equipped with a 60 tooth ring kit. Set Master Setpoint 1 (CP-01) so

that the product is in the oven for 20 seconds. Set Master Setpoint 2

(CP-02) so that the product is in the oven for 15 seconds.

Table 3-33 shows the scaling Control Parameters that would be entered in the

MLP–Trim for this example.

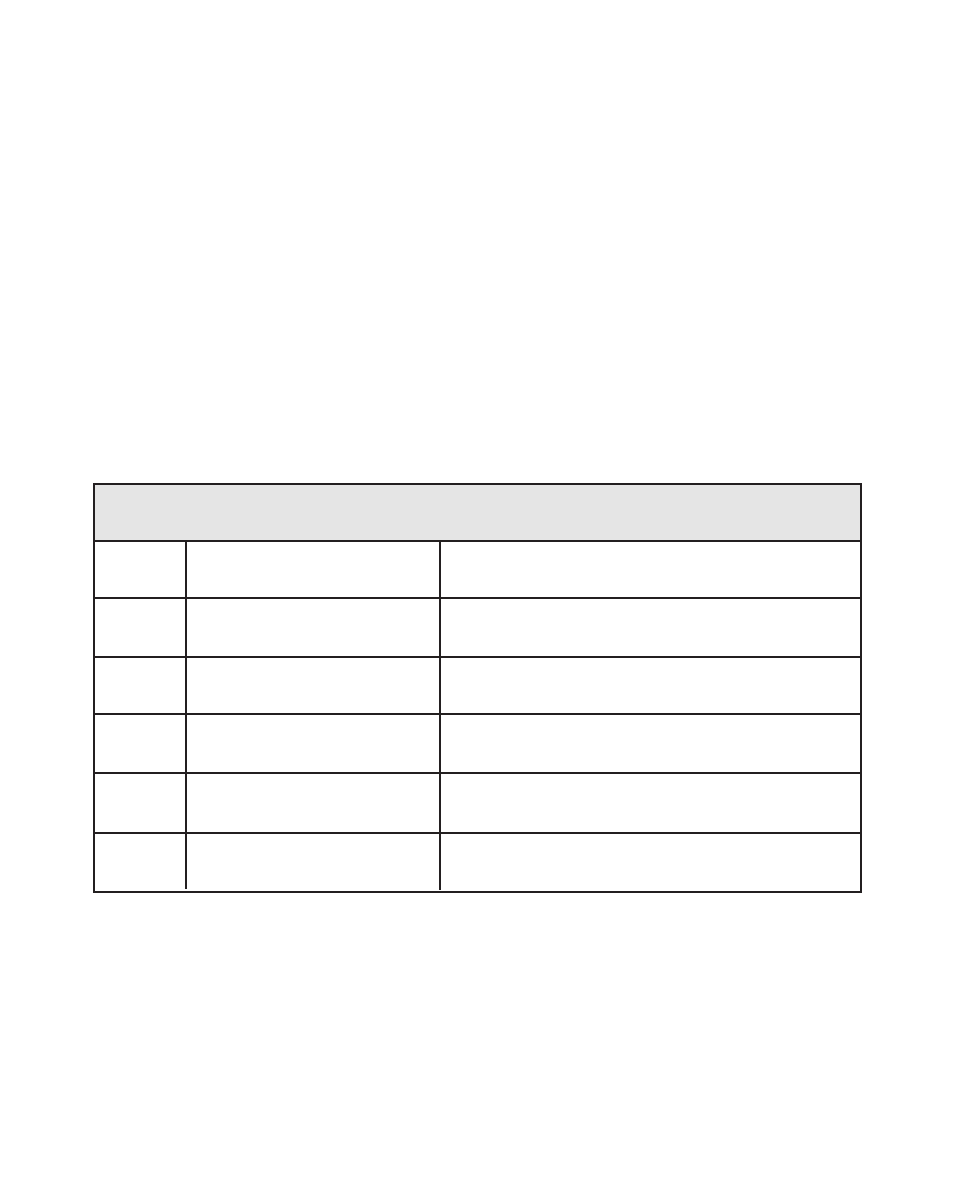

Table 3-33 Inverse Master Mode Control Parameters Example

CP

Parameter Name

Parameter Value

CP-62

Inverse Scaling

2

CP-31

PPR Feedback

60

CP-34

Max RPM Feedback

1500

CP-20

Master E.U.

10.0

CP-01

Master Setpoint 1

20.0

CP-02

Master Setpoint 2

15.0

After the Scaling and the Master Setpoints for your system have been entered, you can

enter the Acceleration/Deceleration Control Parameters for the Inverse Master mode.

Acceleration/Deceleration is discussed in

Operation: Control Parameters, Acceleration/

Deceleration

.

The following section demonstrates how to enter Control Parameters for the Inverse

Follower mode of operation.