Ken Tool Bendix ADB22X-V Air Disc Brakes User Manual

Page 7

7

2.1 BRAKE PAD AND ROTOR INSPECTIONS

Visual checks of the condition of the brake pad/rotor wear

can be made without removing the wheels. Where dust

guards are not used, the top of the pads and part of the

rotor are visible through the opening at the top of the brake.

Other visible portions of the rotor can be inspected at the

same time.

Unless a vehicle has been stored for some time, the main

rotor surfaces that contact the pads will always appear to

be shiny. Surface rust on these surfaces would indicate a

malfunctioning brake that should be inspected immediately.

Pads are 1.181 in. (30 mm.) thick when new and must be

replaced when they reach 0.433 in. (11 mm.). Rotors are

1.77 in. (45 mm.) thick when new and must be replaced

when they reach 1.46 in. (37 mm.). See Section 4.3 for

further inspection criteria.

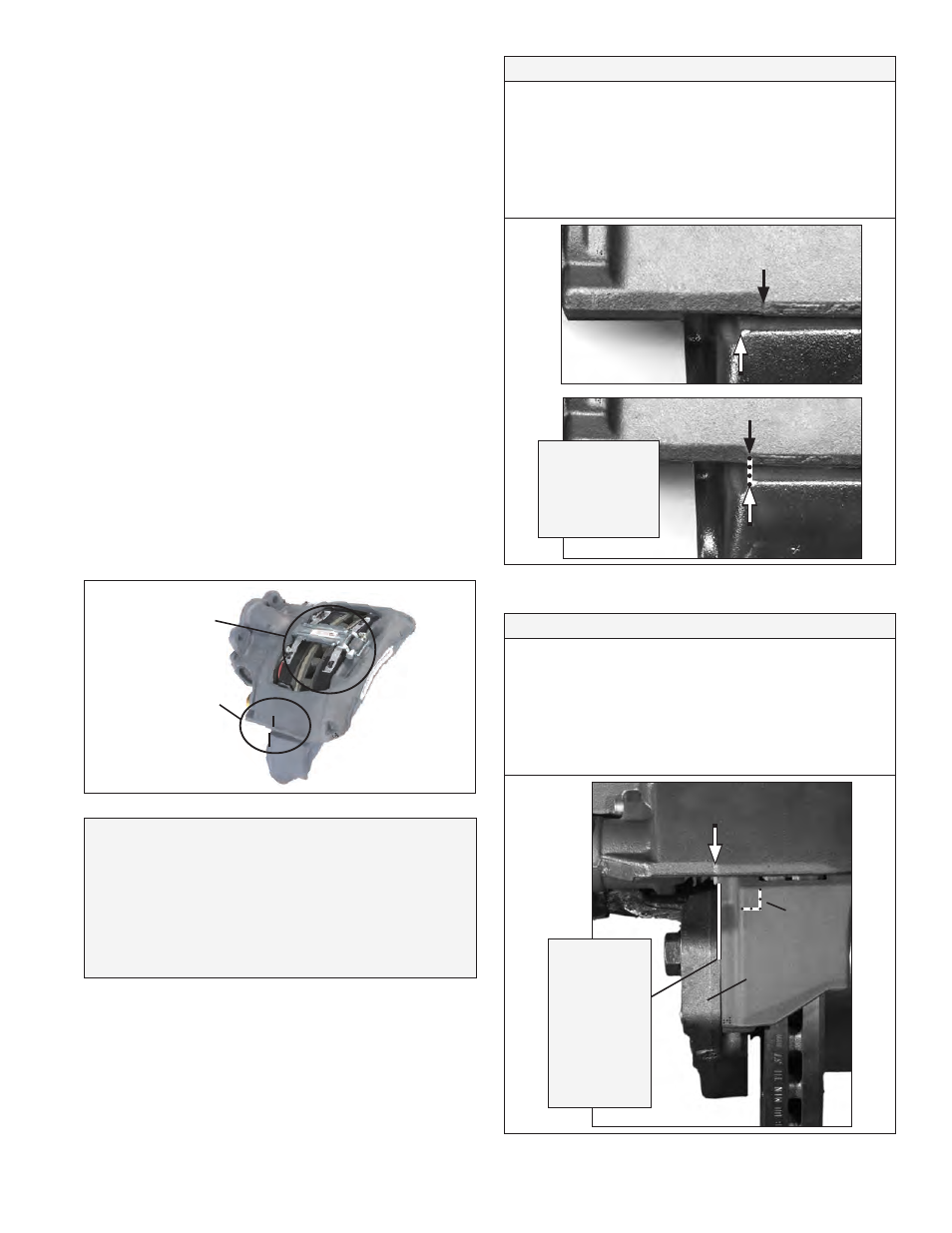

2.1.1 Electronic Wear Indicators

Use the dash indicator(s) and/or a hand-held diagnostic

tool to regularly monitor the pad wear. (See Section 5.2.)

2.1.2 Mechanical Wear Indicators

See Figure 9 for the location of the mechanical wear

indicators. There are two types (See Figure 10 for Style A

and Figure 11 for Style B).

Location of Wear

Indicator Notches

(Both sides of brake)

Quick Visual

Inspection of Pad

Thickness and Rotor

FIGURE 9 - LOCATION OF WEAR INDICATORS

Note: These mechanical wear indicators do

not constitute “out-of-service” criteria. These

inspections only show when to schedule a full wheel-

removed inspection of the brake pads and rotor.

The thicknesses of the pad and rotor will both affect

the wear indicator position at which maintenance is

actually needed.

Wear Indicator Style A:

Where both the carrier and caliper have an

indicator notch.

Compare the relative position of two notches cast into

the carrier and caliper. When the two notches align,

it is time to schedule a full wheel-removed inspection

of the pads and rotor.

Notch in the

caliper

Notch in the

carrier

When the notches

line up, it is time

to schedule an

inspection of the

pads and rotor

FIGURE 10 - STYLE A - WHEN BOTH CARRIER AND CALIPER

HAVE A CAST NOTCH

Wear Indicator Style B:

Where only the caliper has an indicator

notch.

When the notch in the caliper aligns with the front

edge of the torque plate, it is time to schedule a full

wheel-removed inspection of the pads and rotor.

Torque

plate

No notch

in the

carrier

Notch in

the caliper

When the

torque plate

edge lines up

with the notch,

it is time to

schedule an

inspection of

the pads and

rotor

FIGURE 11 - CARRIER WEAR INDICATOR NOTCH AND BACKING

PLATE ALIGNMENT