Ken Tool Bendix ADB22X-V Air Disc Brakes User Manual

Page 27

27

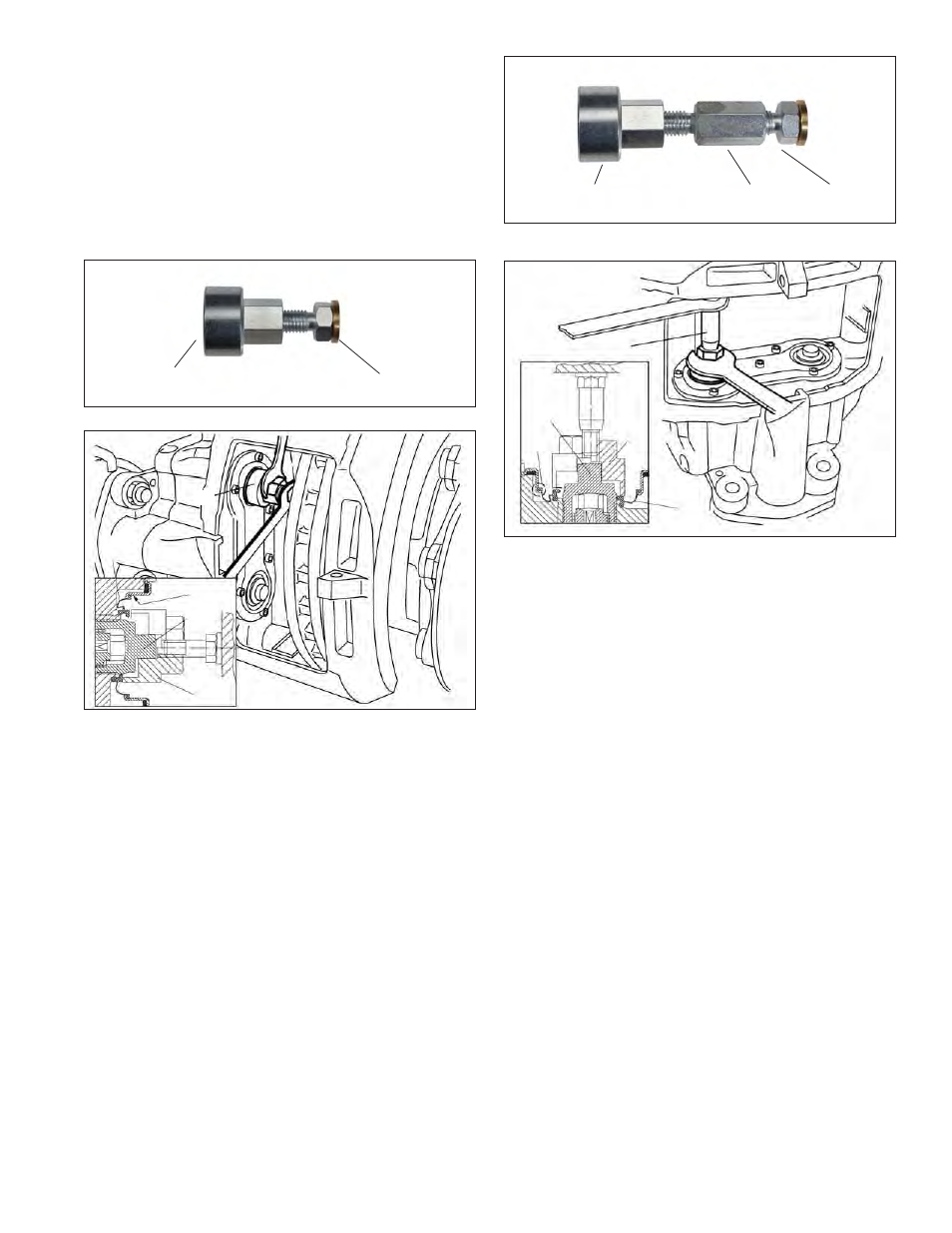

To install inner seals where the caliper is on the vehicle:

5.5.12 Position the replacement inner seal (22) over the

threaded tube (16). See Figures 52 and 53 for the

tools and installation arrangement used. Position

the L1 (T3 + T9) with the short spacer (T3) in

position as shown in Figure 53. Guide the tool

over the end of the threaded tube (16). Install the

new inner seal (22) into position by rotating the

adjuster nut on the T3 portion of the tool, using an

open-ended wrench.

T9 / KT09

T3 / KT03

FIGURE 52 - ON-VEHICLE INNER SEAL TOOL (L1)

L1

T9

16

X

22

FIGURE 53 - ON-VEHICLE INNER SEAL INSTALLATION

To install inner seals where the caliper has been

removed from the vehicle:

5.5.13 Position the replacement inner seal (22) over the

threaded tube (16). See Figures 54 and 55 for the

tools and installation arrangement used. Position

the combination tool L2 (T4 + T3 + T9) with the

long spacer (T4) in position as shown in Figure 55

- typically the threaded tubes need to be partially

retracted to allow the tool to set the inner seals

into position. Guide the tool over the end of the

threaded tube (16). Install the new inner seal (22)

into position by rotating the adjuster nut on the T4

portion of the tool using an open-ended wrench.

T9 / KT09

T4 / KT04

T3 / KT03

FIGURE 54 - ON-VEHICLE INNER SEAL INSTALLATION TOOL

(L2)

L2

16

X

L2

22

FIGURE 55 - OFF-VEHICLE INNER SEAL INSTALLATION

CAUTION: To confi rm that the inner seal has been

correctly installed, begin to extend the threaded tubes

(16) by turning the shear adapter clockwise by 4-5

turns. Watch as the threaded tube extends. Inner seals

that are installed correctly WILL NOT ROTATE as the

threaded tube extends.

5.5.14 Grease the threaded tubes and center posts.

Retract the threaded tubes.

5.5.15 Install the new tappet bushing (161) onto the center

post of each threaded tube (16) by hand. By hand,

ease the tappet bushings onto the center post of

the threaded tubes and they will snap into position.

5.5.16 The sealing seat in the caliper for tappet and boot

assemblies (13) must be clean and free of grease.

Wipe the opening with a clean shop rag. Place a

tappet and boot assembly (13) in position over the

center post and tappet bushing.

To install tappet and boot assemblies where the caliper

is on the vehicle:

5.5.17 See Figures 56, 57 and 58. Use tool B1, comprising

tools T1, T2, and T3 to press the boot into position.

The tool is then reversed, and the nylon disc (T24)

is inserted into the T1 “cup” (combination tool ‘B2’).

Holding the T1 handle, turn the nut on the T3 tool to

fully install the tappet onto the tappet bushing (161).