Ken Tool Bendix ADB22X-V Air Disc Brakes User Manual

Page 13

13

Bendix air disc brakes are precision-engineered braking

mechanisms. The “friction couple” braking characteristics

have been carefully optimized — and the rotor design and

materials have been matched with special formulation

brake pads for optimal performance. In all cases, use

brake pads with the type of backing plate and lining material

originally supplied by the vehicle manufacturer.

CAUTION: When replacing brake pads and rotors,

use only Bendix

®

brand replacement pads and rotors

and/or those approved by the OEM. Non-approved

replacement disc pads or rotors can cause excess

wear to brake components, and can increase the risk

of rotors cracking, etc.

4.4 INSPECT THE ROTOR

CAUTION: Follow all safe maintenance practices.

Identify if the rotor is a Bendix

®

Splined Disc

®

, or

conventional rotor (See Section 1.03). Rotors should be

inspected regularly (See Section 2.0 for recommended

inspection schedule) and at each pad change.

4.4.1 Measure the thickness of the brake rotor at the

thinnest point (Dimension “E” in Figure 22). Avoid

measuring near the edge of the rotor as minor burrs

may result in inaccurate measurement. Replace

the rotor when the minimum thickness of 1.46 in.

(37 mm.) is reached.

4.4.2 Inspect the rotor surface. See Figure 25. The type

of rotor, and also the size, depth and direction of

the imperfections, must all be considered.

NOTE:

If surface wear conditions F through J are

in the permitted range, the rotor is still usable until

it reaches the minimum acceptable thickness of

1.46 in. (37 mm.).

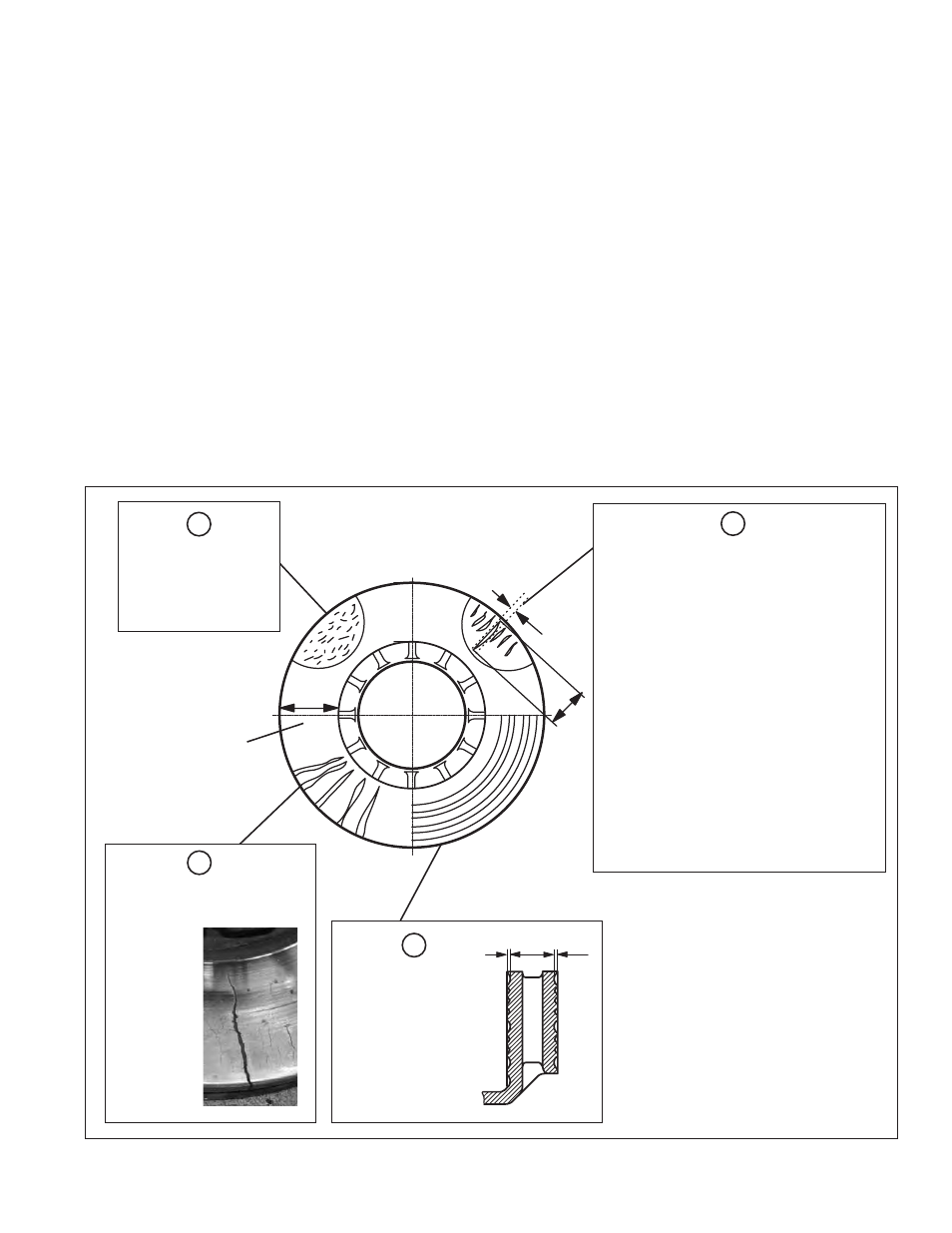

FIGURE 25 - EXAMPLES OF ACCEPTABLE AND NON-ACCEPTABLE ROTOR CONDITIONS

Area

F

Area

H

Area G

f

Area J

Cracks reaching

either edge of the

G

H

rotor

are not

acceptable

for either

type of

rotor

Circumferential

grooves, as in Area

J, are acceptable

if less than 0.06 in.

(1.5 mm) deep.

J

• For standard Bendix rotors, cracks

running in a radial direction — like

spokes of a wheel (see Area H) — less

than 0.06 in. (1.5 mm) deep or wide

are acceptable if they do not reach

either edge (see G). Cracks are only

acceptable if the length of the crack is

less than 75% of dimension “f” (the width

of the rotor contact area).

• For Bendix Splined Disc rotors, radial

cracks are only acceptable if they are

less than 0.04 in. (1.0 mm) deep or

wide and if they do not reach either edge

(see G). Crack lengths must be less

than 75% of dimension “f” (the width

of the rotor contact area).

In addition, follow the

recommendations of the

vehicle manufacturer.

Note: Axles should

have either all Bendix

Splined Disc (or all

conventional) rotors.

Rotor

Friction

Surface

Width “f”

No action is needed

f o r s m a l l c r a c k s

s p r e a d o v e r t h e

surface (e.g. Area F)

F