5 guide pin bearing inspection, 3 machining (grinding or turning) rotors, Warning – Ken Tool Bendix ADB22X-V Air Disc Brakes User Manual

Page 14: 4 rotor replacement

14

Caliper

Movement

1

Caliper

5

Guide Pin

9

Inner Boot

9 Inner Boot

7

Brass Bushing

10

Cap

6 Guide Sleeve

4 Guide Pin

39

Caliper Bolt

Outboard

Inboard

68

Cap

SHORT

BEARING SIDE

LONG

BEARING SIDE

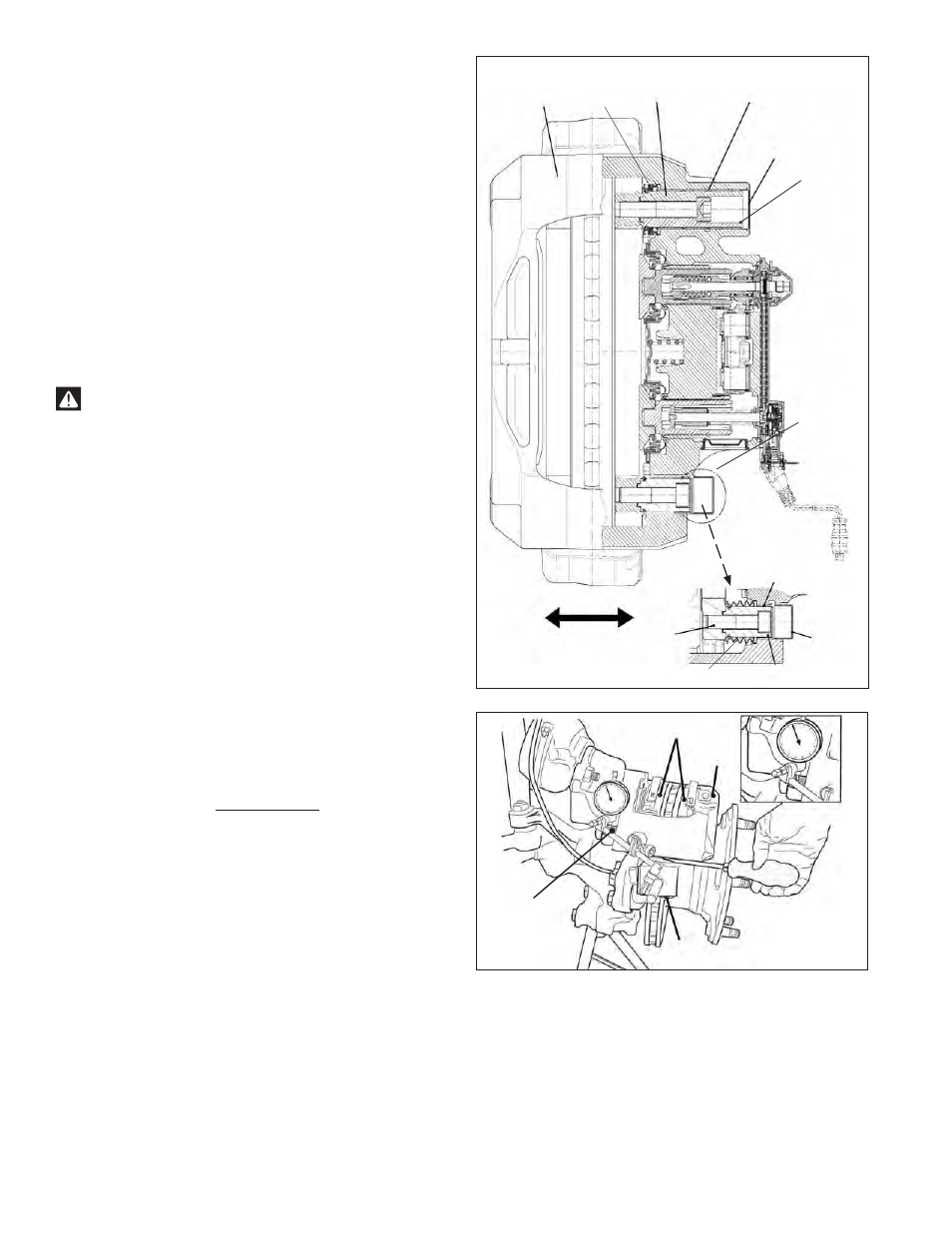

FIGURE 26 - GUIDE PINS

12 Pad Assembly

1

Carrier

2

Caliper

Magnetic

Dial-Gauge

Measures

Range Here

FIGURE 27 - MAGNETIC DIAL-GAUGE IN USE

4.5.1 See Figures 28 and 29. With the wheel removed,

remove the pad retainer bar (11). Temporarily

replace the pads with two new pads (12). Attach

a magnetic dial-gauge holder to the carrier (2) on

the short bearing side of the caliper (1). Use the

measuring point on the caliper (1) - see the callout

in Figure 29. Press the caliper in the direction of

the carrier (2) and set the dial-gauge to zero.

4.4.3 Machining (Grinding or Turning) Rotors

Bendix rotors are normally service-free. In the case of

severe grooving of the entire friction surface, however,

CONVENTIONAL ROTORS may be turned when changing

pads, to increase the load-bearing surface.

MACHINING OF BENDIX

®

SPLINED DISC

®

ROTORS IS

NOT PERMITTED.

CAUTION: Always maintain air disc brake pads and rotors

within specifi cations. Excessive pad or rotor wear will

degrade braking performance.

Periodic inspection of the Bendix Splined Disc attachment

hardware is recommended to ensure optimum braking

performance. Bendix recommends verifying the torque on

the spring element fasteners whenever a brake inspection

is performed.

WARNING!

AFTER MACHINING/TURNING, THE

MINIMUM ROTOR THICKNESS MUST BE AT LEAST

1.535 - 1.575 IN. (39 - 40 MM.). ALSO, CHECK THE

VEHICLE MANUFACTURER’S RECOMMENDATIONS.

FAILURE TO COMPLY MAY RESULT IN BRAKE FAILURE

AND IN SERIOUS INJURY OR DEATH. MACHINING OF

BENDIX SPLINED DISC ROTORS IS NOT PERMITTED.

4.4.4 Rotor Replacement

An axle is permitted to have only all Bendix Splined

Disc, or all conventional, rotors.

When replacing rotors, be sure to adhere to the vehicle

manufacturer’s recommendations, including bolt tightening

torques. It is recommended to install only Bendix

®

brand

rotors, and also that the pads should be replaced (as an

axle set) at the same time.

Non-Bendix

®

brand rotors. If a non-Bendix

®

brand rotor is

used, confi rm that it complies to the vehicle manufacturer’s

recommendations.

CAUTION: The use of non-approved brake rotors may

reduce levels of safety and invalidate the warranty.

See Section 5.7 for re-installation procedures.

4.5 GUIDE PIN BEARING INSPECTION

CAUTION: Follow all safe maintenance practices.

This guide pin inspection should be carried out if the

technician cannot move the caliper during a Caliper

Movement Test (Sections 2.2 and/or 4.1).

Measure the “play” (range of movement) in the guide

pin bearings: