2 pad replacement – Ken Tool Bendix ADB22X-V Air Disc Brakes User Manual

Page 20

20

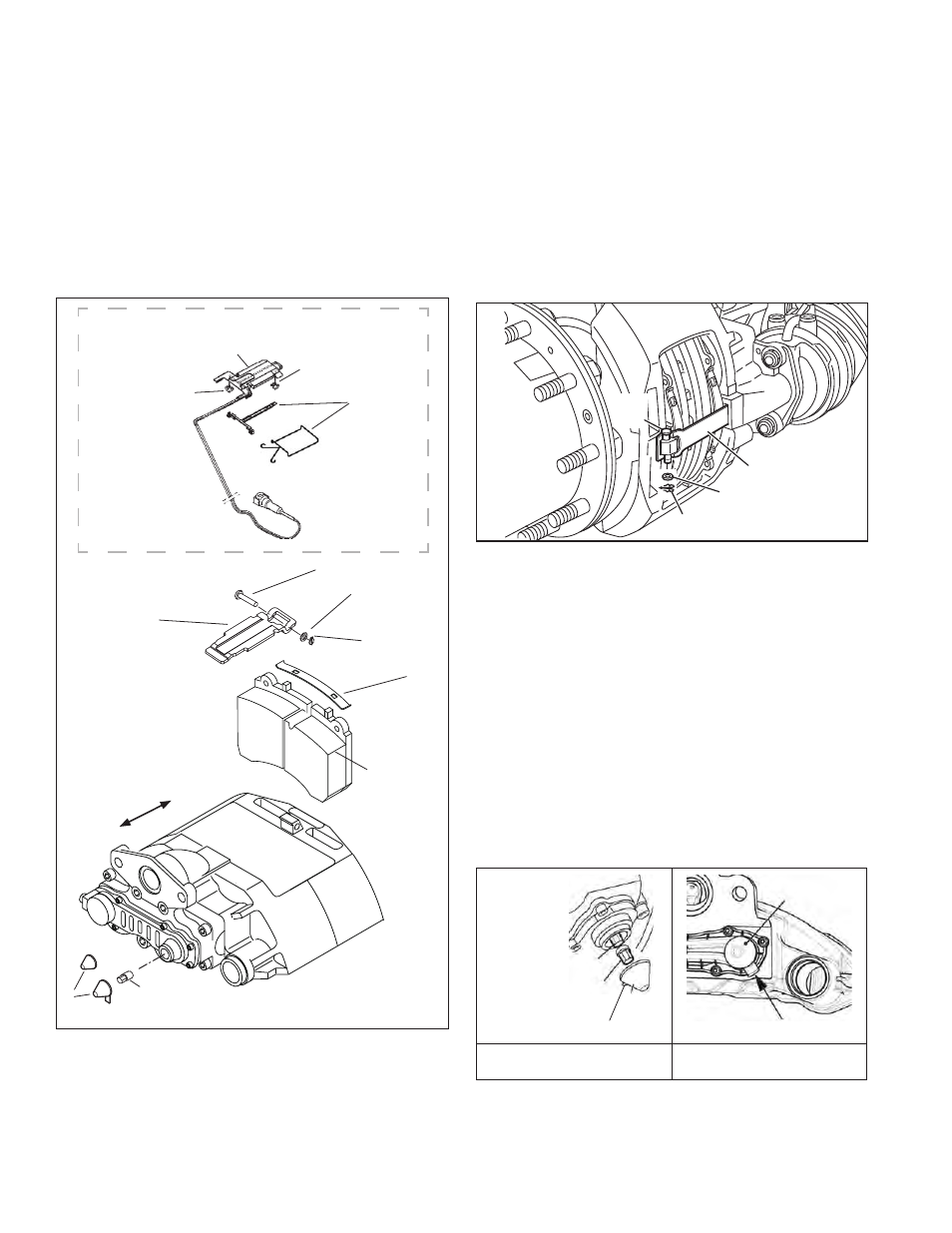

and retain the mounting hardware for the cable

protection plate. The cable protection plate can

then be set aside while servicing the pads. Note the

position of the sensors in the brake pad channels,

and carefully remove them. In most cases you do

not need to release the cable connector in order to

move the sensors away from the pad installation

work area. Inspect the wear sensors - replace if

damaged or abraded.

5.2.4 See Figure 36. Remove and discard the pin

retention clip (26) and washer (5).

44

Pin

26 Spring Clip

45 Washer

11 Pad Retainer Bar

FIGURE 34 - PAD RETAINER BAR REMOVAL

5.2.5 While pressing against the pad hold down bar,

remove the pad retainer bar pin (11). Discard the

hold down bar.

5.2.6 With the spring brake released (or caged), remove

the adjuster cap (37) using the tab, taking care not

to move the shear adapter (61). Note: One of two

styles of adjuster cap (stamped metal or plastic

adjuster cap) may be found; use the same style as

a replacement in step 5.2.21.

5.2.7 Inspect the sheer adapter (61). If significant

corrosion and/or damage is present, remove the

adjuster adapter using needle-nose pliers and

replace with the adapter supplied in the kit and

clean as necessary.

61 Adapter

23 Adjuster

37

Cap

Tab

Tab

37

Cap

FIGURE 35 - EXPLODED VIEW

OF ADJUSTER AND ADAPTER

FIGURE 36 - CAP INSTALLED:

TAB LOCATION

For illustration purposes, the exploded view (Figure 36)

shows the adjuster (23) and shear adapter (61) separated.

When using the adjuster mechanism, always have the

shear adapter installed on the adjuster.

5.2 PAD REPLACEMENT

5.2.1 CAUTION: Follow all safe maintenance

practices, including those listed on page two of

this document. Park the vehicle (by other means

than the foundation brakes) on level ground and

chock the wheels.

The Bendix DVD (BW7356) shows this procedure.

Important: If the vehicle is equipped with spring brakes,

cage the spring brakes on all axles to be worked on.

Consult the vehicle manufacturer’s instructions as

necessary.

Ou

tbo

ard

Inboard

12

2

11

44

45

26

61

37

ELECTRONIC WEAR

SENSOR

(if installed)

103

Cable to Electrical

Supply

104

Cable Protection

Plate

101

Sensor

101

Sensor

105

Cable Guide

(2 alternate

designs used)

FIGURE 33 - PAD REPLACEMENT

5.2.2 Raise the complete axle to be worked on until the

tires clear the ground. See the vehicle maintenance

manual instructions for removing the wheels.

5.2.3 If the air disc brake is equipped with an electronic

wear sensor indicator (see top of Figure 35), remove