Ken Tool Bendix ADB22X-V Air Disc Brakes User Manual

Page 26

26

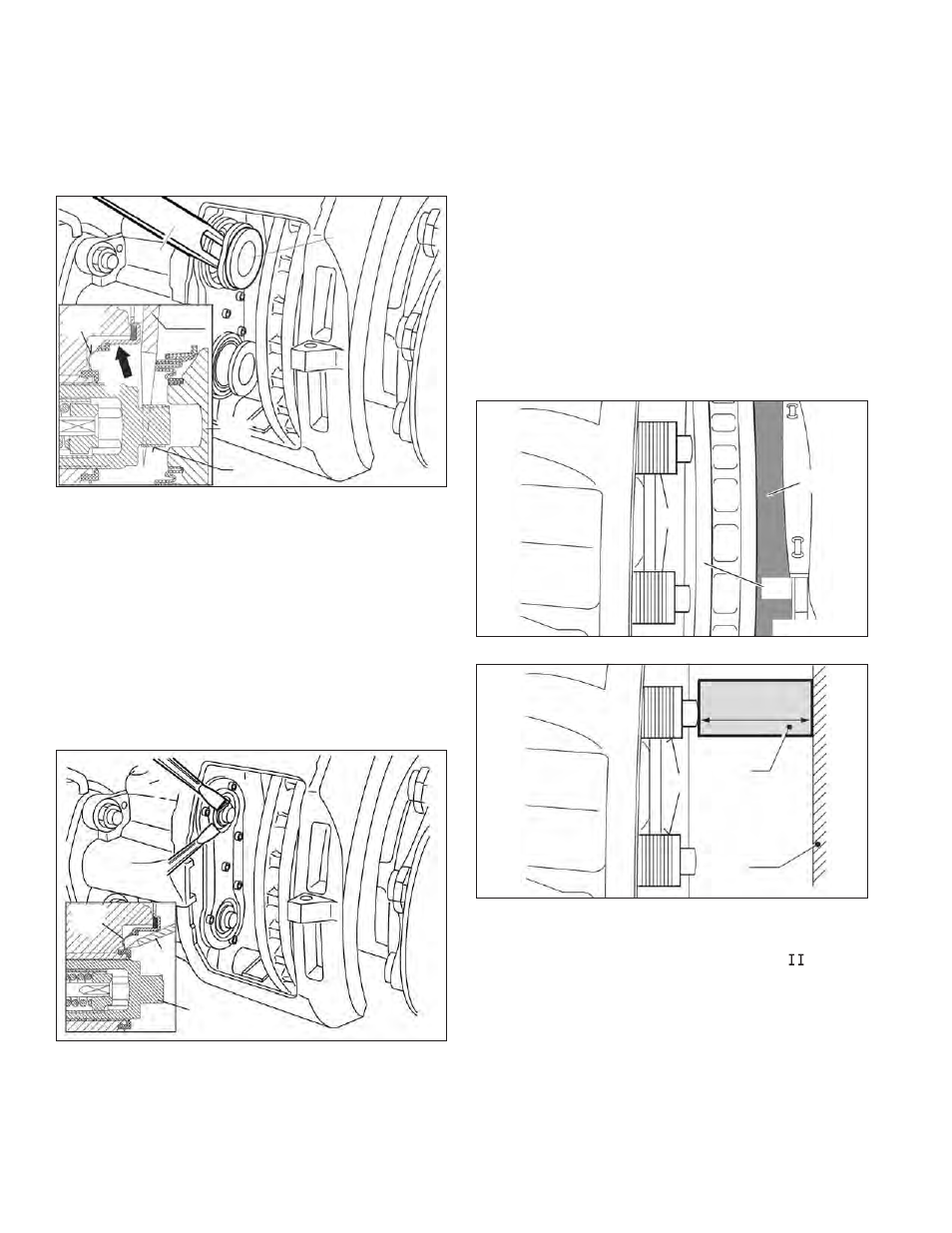

Figure 47 inset) should be used to move the boot

and allow the wedge fork (“A” in Figure 48) to be

inserted. CAUTION: Do not insert the screw driver

more than ¼ inch. Take care not to damage the

inner sealing face (see arrow “X” in Figure 49).

Gouges or grooves will prevent a good seal and

will require that the caliper be replaced.

13

T15

22

A

13

161

X

FIGURE 48 - WEDGE TOOL USE

5.5.6 The tappet and boot assemblies (13) can then be

removed from the threaded tubes (16) by using the

wedge fork (T15). Be sure to orient the wedge tool

with the tapered side towards the tappet.

5.5.7 Remove the old tappet bushings (161).

5.5.10 See Figure 49. Carefully remove the inner seal

using one or two fl at-blade screwdrivers as shown.

Caution: Do not insert the screwdrivers so far that

they come into contact with the threaded tubes.

Damage to the threaded tubes would require that

the brake be replaced.

A

22

16

FIGURE 49 - INNER SEAL REMOVAL

5.5.8 Inspect the inner sealing face for damage. If

damage is found that would cause the inner seals

not to be able to seal properly, the caliper/carrier

assembly must be replaced. Clean the area around

the inner seal.

5.5.9 Inspect the threaded tubes (16). See Figures 50

and 51. Extend the tubes, but by less than 1.75 in.

(44.5 mm), by turning the shear adapter (61)

clockwise. Inspect the threads for rust, corrosion, or

damage etc. If there is evidence of damage to the

threads; signifi cant rust; or corrosion, the caliper/

carrier assembly must be replaced.

If the technician is working with the caliper on the

vehicle, the technician may place a new brake pad

(12) into the outboard gap to help avoid the loss

of thread engagement of the threaded tubes. See

Figure 51.

If the work is being carried out at a workbench, the

technician may insert a 2.76 in. (70 mm) spacer

(See callout “E” in Figure 52) into the caliper (1) to

help avoid the loss of thread engagement.

12

16

46

FIGURE 50 - USE OF A NEW BRAKE PAD AS A SPACER

E

16

1

2.76 in.

(70 mm)

FIGURE 51 - USE OF A SPACER (OFF-VEHICLE INSPECTION)

5.5.11 For threads that are in good condition, grease the

threads with white grease (Part No.

14525 or

K021964). Before installing the replacement inner

seals (22), retract the threaded tubes by turning the

shear adapter (61) counter-clockwise.

Note: If the shear adapter fails while you are retracting

the threaded tubes, you may try again with another

(new) shear adapter. If this also fails, this indicates

that the adjuster mechanism is damaged and the

caliper must be replaced.