3 caliper/carrier/actuator assembly – Ken Tool Bendix ADB22X-V Air Disc Brakes User Manual

Page 22

22

FIGURE 40 - RUNNING CLEARANCE ADJUSTMENT

5.2.19 Move the caliper to the full outboard position.

5.2.20 Using a 10 mm. six-point box wrench, turn the Shear

Adapter (61) counter-clockwise and listen for

the sound of 3 clicks as the mechanism backs-off

(increases) the running clearance. Note: Do not

use an open-ended wrench as this may damage

the adapter. (See Figure 40).

5.2.21 Select the correct replacement adjuster cap from

those supplied with the kit. Lightly grease adjuster

cap with Renolit HLT2 white grease (part number

14525) and install the cap.

5.2.22 Push the new pad retainer bar (11) into the groove

of the caliper. Press down on the pad retainer bar,

and insert the pad retainer pin (44), with the pin

pointing downwards, where possible. Install the

supplied washer (45) and then the spring clip (26).

5.2.23 Apply and release the brakes. The hub should

turn easily by hand after applying and releasing the

brake.

5.2.24 Re-check the running clearance. Readjust if

necessary.

5.2.25 Reinstall the wheel, following the vehicle manual

instructions.

WARNING!

The brake pads and rotor must be maintained within

the recommended wear limits. Failure to monitor wear

and replace the brake pads and rotor when required

may result in diminished brake performance.

5.3 CALIPER/CARRIER/ACTUATOR

ASSEMBLY

5.3.1 CAUTION: Follow all safe maintenance

practices, including those listed on page two of

this document. Park the vehicle (by other means

than the foundation brakes) on level ground and

chock the wheels.

The brake pads must be removed (See Section

5.2.0) and actuator disconnected (and caged if

a spring brake), see Section 5.4.0.

CAUTION: When using a hoist to support the

air disc brake, do not attempt to use the pad

retainer bar as a bracing point. It is not designed

to support the weight of the brake. Use instead

a brace (or chain) wrapped around the entire

brake to attach the hoist.

5.3.2 In all cases check that the current hose routing

arrangement does not restrict the full travel of the

caliper before beginning work on the assembly.

5.3.3 Disconnect the air hose(s) from the service or spring

brake chamber.

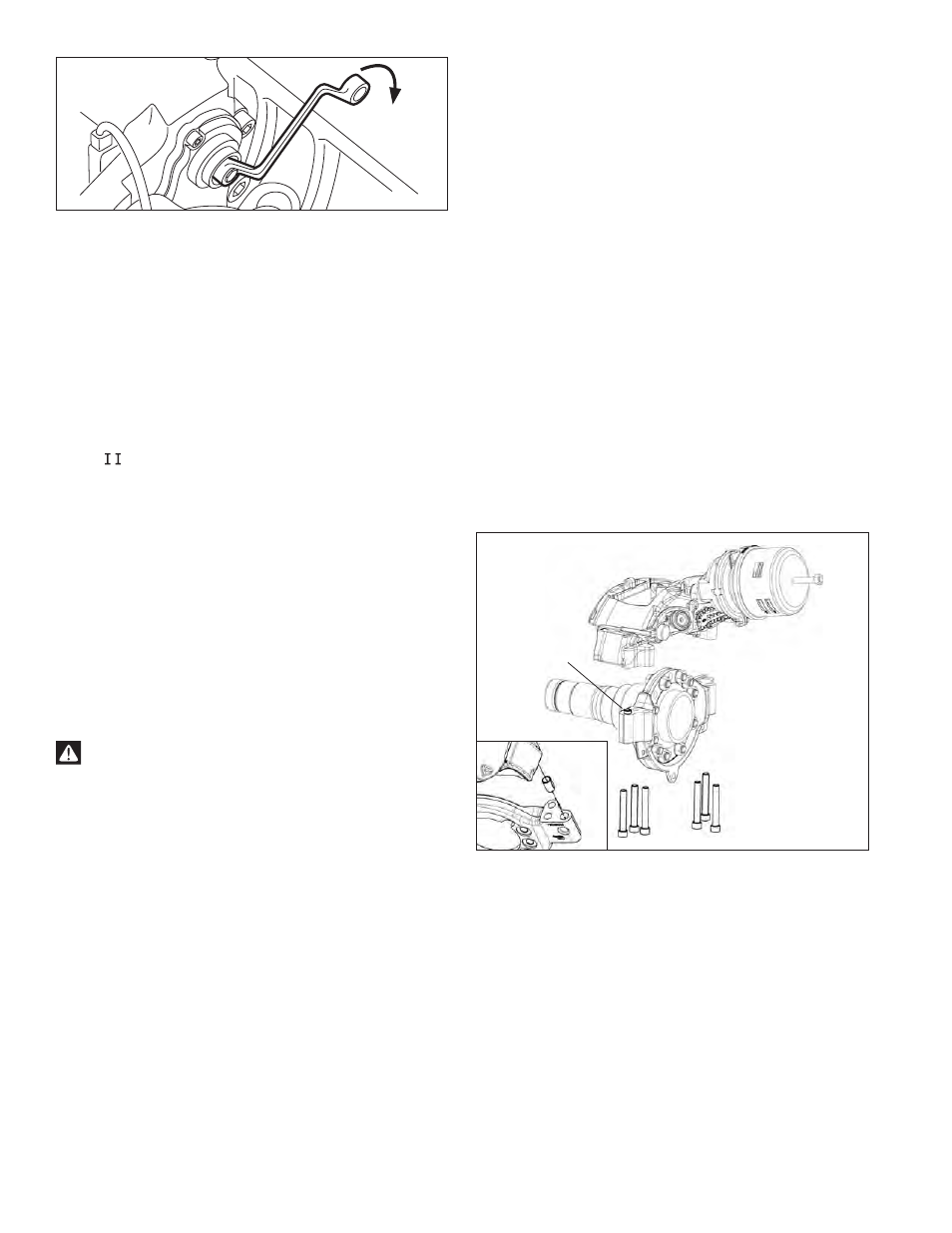

Vertical Mounting Bolt Style

Mounting Bolts

(6 total - washers

not required)

Anchor Plate/

Torque Plate

Caliper/Carrier Assembly (Showing

Spring Brake Actuator )

Alignment

Bushing

Alignment

Bushing

FIGURE 41 - VERTICAL MOUNT CALIPER/CARRIER

5.3.3 See Figure 41. Supporting the air disc brake by

necessary means, remove the six (6) mounting

bolts/washers and discard. Note: Bendix strongly

recommends that during re-assembly these bolts

are replaced - see your vehicle manufacturer for

replacement hardware. Lift the caliper up off the

anchor plate.

The vertical bolt assembly includes an alignment bushing.

This bushing must be saved for re-use during re-

assembly of the brake. The bushing mounts in the torque

plate and maintains the correct alignment of the brake

assembly relative to the rotor.