Specification, How a hydrotech water softener works, Timer behavior during regeneration – Hydrotech 6200 SXT Automatic Meter Initiated Water Softener User Manual

Page 5

4

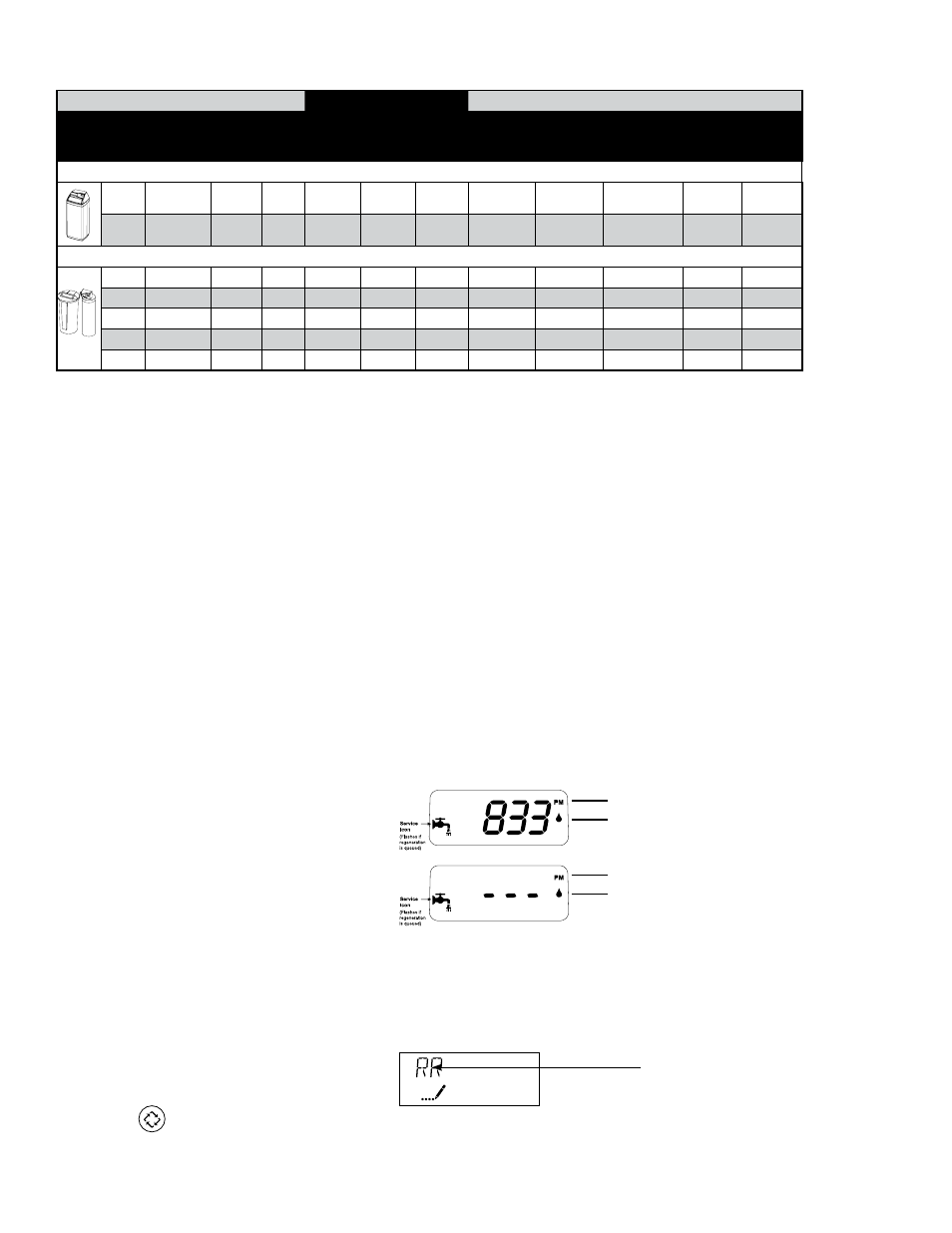

Specification

NC indicate cabinet model, NT indicate twin tank model

Working Temperature = 34-110°F (1-43°C)

(Do not subject the unit to freezing temperatures)

Working Pressure = 20-125 PSIG (137-861 kPa)

Voltage = 120V / 60 Hz

Pipe Size = 3/4”

• At the stated service flow rates, the pressure drop through these devices will not exceed 15 psig.

• Changing salt settings from factory setting may require changing injector sizes to achieve stated capacities

• The manufacturer reserves the right to make product improvements which may deviate from the specifications and descriptions stated herein,

without obligation to change previously manufactured products or to note the change.

* Do not use water that is microbiologically unsafe without adequate disinfection before or after the system.

* Iron content must not exceed 1 ppm. Beyond 1 ppm an iron softener must be used. Periodic media cleaning is required by

Pro-Res Cleaner is iron level exceed 0.3 ppm

† USA customers will need to add “-4” to the item numbers for ordering.

Capacity Grains

Unit

†

Item #

Model #

Tank

Size

Media

(CF)

10 lbs of

Salt/CF

of Resin

6 lbs of

Salt/CF

of Resin

3 lbs of

Salt/CF

of Resin

Service

Flow

Rate (gpm)

Backwash

Flow Rate

(gpm)

Brine Tank

Dimension

(W X D X H)

in.

Salt

Capacity

(lbs)

Shipping

Weight

(lbs)

Hydrotech Cabinet Softeners

2400

HSC75

9 x 35

0.75

21,400

16,200

11,600

8

1.5

14 x 22 x 42

250

90

2401

HSC10

10 x 35

1

30,000

23,000

16,000

9

2

14 x 22 x 42

240

105

Hydrotech Twin Tank Softeners

2402

HST75

8 x 44

0.75

21,400

16,200

11,600

8

1.5

15 x 36

224

85

2403

HST10

9 x 48

1

30,000

23,000

16,000

10

2

15 x 36

224

100

2404

HST15

10 X 54

1.5

25,500

19,500

19,500

12

2.4

18 x 33

308

140

2405

HST20

12 X 52

2

34,000

26,000 32,000

13

4

18 x 33

308

190

2406

HST25

14 X 50

2.5

42,500

32,500

22,500

13

5

18 x 33

308

230

How a Hydrotech Water Softener Works

Water softeners remove hardness in the water by exchanging particles in the water, or ions. They remove hard ions the

calcium and magnesium in the water by trading it for sodium ions producing soft water. Unlike the calcium and magnesium,

sodium stays dissolved in water and does not form a scale. Sodium also does not interfere with the cleaning action of soaps.

The sodium is released by a charged resin contained in the softener, this resin also traps the calcium and magnesium ions.

Eventually this resin releases all of its sodium and has filled up with other ions, so it then must be regenerated. Regeneration

is accomplished by washing the resin with a salt saturated brine solution that removes the calcium and magnesium while

replenishing the sodium. This is why the softener requires a brine tank and salt.

The water softener can run for days before running out of sodium, and when it does, the sodium is replenished

in only a matter of a few hours.

In normal operation, the Time of Day display will alternate being viewed with the Volume Remaining display. This display will

be in gallons or liters. As treated water is used, the Volume Remaining display will count down from a maximum value to zero

or (---). Once this occurs, a regeneration cycle will be initiated at the Set Regeneration Time. Water flow through the valve is

indicated by the Flow Indicator that will flash in direct relationship to flow rate.

Example

833 Gallons of Treated

Water

Remaining

0 Gallons of Treated

Water

Remaining

Timer Behavior During Regeneration

In regeneration, the control will display a special regeneration display. In this display, the control will show the current

regeneration step abbreviation the valve is advancing to or has reached and the time remaining in that step. The step

abbreviation displayed will flash until the valve has completed driving into this regeneration step position. Once all

regeneration steps have been completed, the valve will return to Service and resume normal operation.

Example

Less than 6 minutes

remaining in Regeneration

Step Rapid Rinse

Pushing the

during a regeneration cycle will immediately advance the valve to the next cycle step position and

resume normal step timing.

Please see the control valve manual for different regeneration step abbreviations.

5

PM Indicator

PM Indicator

Flow Indicator

(Flashing with water flow)

Flow Indicator

(Flashing with water flow)

Regeneration Step

Abbreviation