Hydrotech 6200 SXT Automatic Meter Initiated Water Softener User Manual

Page 34

33

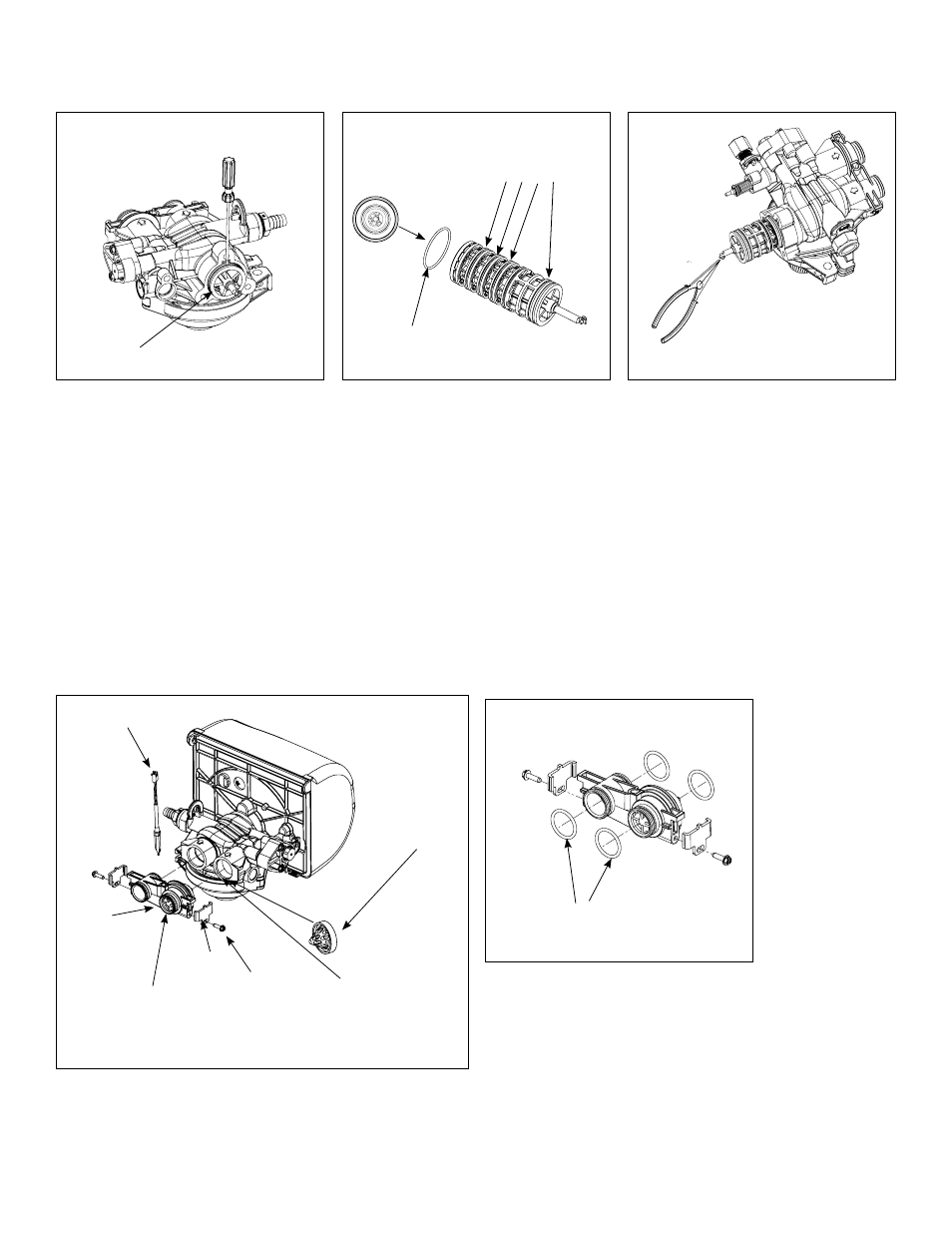

Piston Cartridge Assembly Replacement

Meter Replacement and Service

3. Inspect the inside of the valve to

make sure that there is no foreign

matter that would interfere with the

valve operation.

4. Put food grade silicone grease on

the o-rings of the new piston car-

tridge assembly and install it inside

the valve body.

4. Apply silicone lubricant to four new o-rings and assemble

to four ports on new meter module.

5. Assemble meter to control valve. Note, meter portion of

module must be assembled at valve outlet.

6. Push resin tank back to the plumbing connections and

engage meter ports with bypass valve or yoke.

7. Attach two clips and screws at bypass valve or yoke. Be

sure clip legs are firmly engaged with lugs.

1. Disconnect the meter cable from the meter.

2. Remove two screws and clips at bypass valve or yoke.

Pull resin tank away from plumbing connections.

3. Pull meter module out from control valve.

Screw

Clip

Lubricate O-rings

Flow Meter should be

attached to the outlet

side of the valve

Flow Straightainer

Inside the Outlet

Port

Outlet Port

Meter

Assembly

Meter Cable

This O-ring goes to the

bottom of the cartridge

Cartridge Assembly

All 5 O-rings need to be

inspected for damages

and lubricated

1. Follow steps 1 to 5 of timer

replacement.

2. Use a flat head screw drive on the

notch of the valve body as shown

to loosen the piston cartridge, pull

the cartridge out of the body using

pliers.

5. Reinstall the timer assembly, brine

valve bracket and meter cable.

B

A

1

3

4

4

3

2

1

2

THIS DOCUMENT IS SOLELY THE PROPERTY OF PENTAIR

WATER TREATMENT. REPRODUCTION, USE DISCLOSURE, OR

TRANSMISSION OF THIS DOCUMENT OR DETAILS CONTAINED

HEREIN, IN PART OR IN WHOLE, IS PROHIBITED WITHOUT

THE WRITTEN CONSENT OF PENTAIR WATER TREATMENT

ENGINEERING. THIS DOCUMENT AND ANY COPIES SHALL BE

RETURNED TO PENTAIR WATER TREATMENT UPON WRITTEN

REQUEST.

TITLE

SIZE

SCALE

SHEET 4 OF 4

DWG NO.

REV

Pentair Residential

Filtration

CHECKED

APPROVED

APPROVALS

DATE

THIRD ANGLE

PROJECTION

DRAWN

SOLIDWORKS FORMAT

LEVEL I

LEVEL II

LEVEL III

CRITICALITY SYMBOLS PER QPSP-001.2

DATE AND TIME

D

1:1

5

5

D

C

6

7

8

6

7

8

B

C

D

REVISIONS

DATE

APP'D

DESCRIPTION

REV.

ECN

ZONE

_

A

THIS DRAWING MUST BE COMPARED TO THE ERP SYSTEM TO ENSURE CORRECT REVISION LEVEL PRIOR TO USE.

LAST SAVED IN SMARTEAM:

DO NOT SCALE DRAWING. DIMS. ARE IN INCHES [mm]

INTERPRET DIMS AND TOLERANCES PER ASME Y14.5M -1994

UNLESS OTHERWISE SPECIFIED:

CORNER FILLETS R.005-.020 [.127-.508]

TOLERANCES:

ANGLES :

1

1 PLACE .X:

.015 [0.38]

2 PLACE .XX:

.01 [0.3]

3 PLACE .XXX:

.005 [0.13]

THE COMPONENT, PART, OR ASSEMBLY DESCRIBED IN THIS DOCUMENT MUST COMPLY WITH THE EU (EUROPEAN UNION) DIRECTIVE:

RoHS DIRECTIVE 2002/95/EC,

BR42889