The cmu sensor, Application domain of the cmu sensor, Mode of operation – Fluid Components International CMU User Manual

Page 14: Measuring principle, System configuration, Input, Custody transfer operations

3. The CMU sensor

3.1

Application domain of the CMU sensor

The CMU sensor is intended for use solely for direct and continuous mass flow measurement of liquids

and gases, irrespective of their conductivity, density, temperature, pressure, or viscosity. The sensor is

also intended for use for the direct and continuous mass flow measurement of chemical fluids, suspen-

sions, molasses, paint, varnish, lacquer, pastes and similar materials.

[

]

v

m

F

C

×

⋅

⋅

=

ω

2

3.2

Mode of operation

3.2.1 Measuring

principle

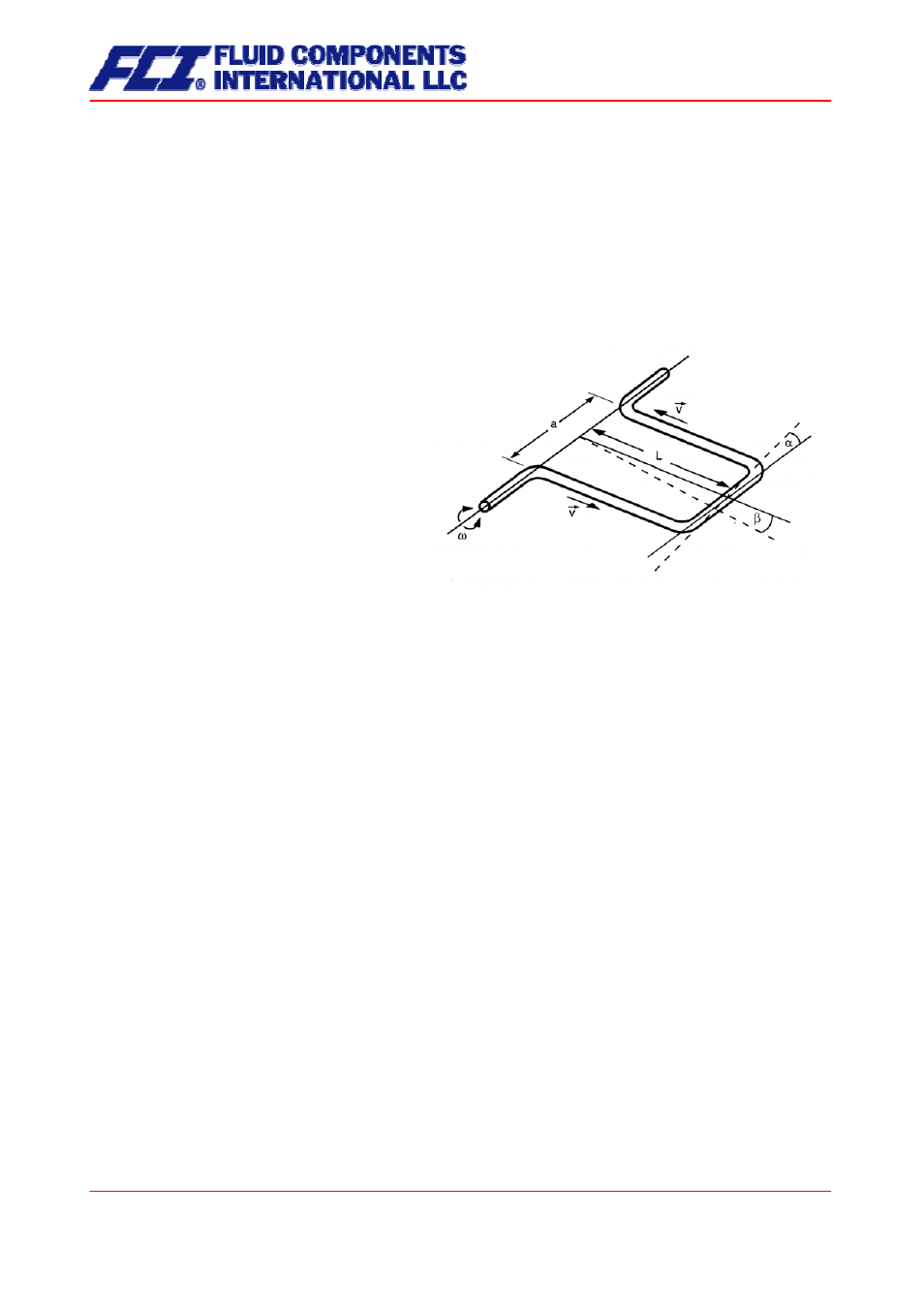

The Coriolis mass flowmeter is based on the

principle whereby in a rotating system a force

(known as the Coriolis force) is exerted on a

mass at a rotation point that is moving towards

or away from this point.

3.2.2 System

configuration

The flowmeter consists of a sensor that is mounted in a pipe, and a transmitter (see Section 5

Application domain of the CT

on pp. 35), that can be directly mounted on the sensor or installed sepa-

rately (e.g. on a wall).

The transmitter oscillates the flow tubes in the sensor over a excitation coil and picks up, via the sensor

coil, the measuring signal which is proportional to the mass flow. After being temperature compensated,

the measuring signal is converted into an analog output signal that is consistent with the measuring range

setting.

3.2.3 Input

Measured variables: mass flow, density, temperature; volume flow is calculated

3.3

Custody transfer operations

Units designated for custody transfer operation may be certified in accordance to the local or national

ordinance. Transmitters ordered for custody transfer applications incorporate special tamper-proof soft-

ware, sealed and certified, that prevents the reset of the internal totalizer.

Page 14 of 112

CMU & CT OPERATING MANUAL