Maintenance safety instructions, Cleaning, Current source sink – Burkert Type SE30EX User Manual

Page 9: Suppl y nc coil pulse input npn/pnp 2 13 pe, 21 3 pe, L+ l

32

→

To access the intrinsic safety barrier switches, remove

the blue mask on the front side.

SE30 Ex

8025 Universal

+

-

L+

L-

+

-

24 VDC ± 10%

/ 230 VAC

B A ON

1 2

1

2

3

CURRENT

SOURCE

SINK

BINA

RY

PE

PE

PE

PE

DI1

DI2

DI3

DI4

DO4

ISOG

FLOW

SENSOR

L+

L-

PE

P-

P+

NC

Iout

PULSE

DO1

Supply

12..36Vdc

Univ

Batch

(AO1)

SUPPL

Y

NC

COIL

PULSE

INPUT

NPN/PNP

2

13

PE

+

-

SENSOR

SUPPLY

LOAD

+5V

L+

(L+)-12V

COIL/PNP

39K

470

2.2K

SENSOR

TYPE

COI

LN

PN/PNP

DO2

DO3

OFF

ON

Intrinsic safety

barrier

Potentially explosive

area

Safe area

Power supply

Put the 2 switches "1" and "2" in the ON

position.

The position of switches

"B" and "A" is indifferent.

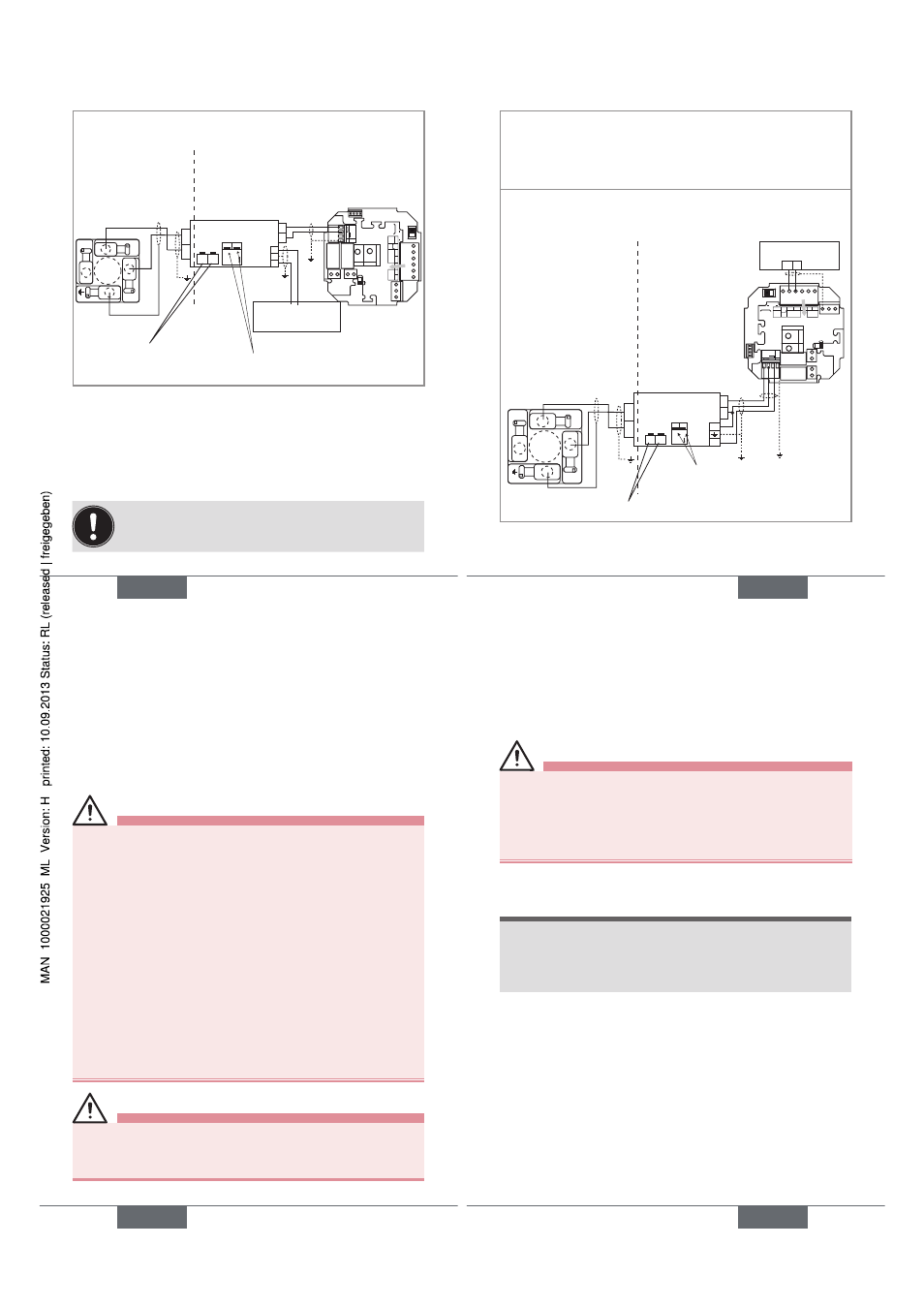

Fig. 7 : Connection between an SE30 Ex and a panel

version of the transmitter 8025 Universal

connection example with the SE30 Ex

and the intrinsic safety barrier, 24 VDc,

powered through the transmitter

Refer to the operating instructions of transmitter 8025

Universal for any other wiring instruction.

English

33

Position of 8025 Universal selectors:

• «SENSOR INPUT LOAD» = «1» (2.2 kΩ)

• «FLOW SENSOR» = «NPN/PNP»

• «SENSOR SUPPLY» = «3» (L+)

→

To access the intrinsic safety barrier switches, remove

the blue mask on the front side.

SE30 Ex

8025

Universal

+

-

L+

L-

+

-

24 V DC ± 10%

B A

ON

1 2

1

2

3

+ -

+

-

CURRENT

SOURCE

SINK

BINARY

PE

PE

PE

PE

DI1

DI2

DI3

DI4

DO4

ISOG

FLOW

SENSOR

L+

L-

PE P- P+

NC

Iout

PULSE

DO1

Supply

12..36Vdc

Univ

Batch

(AO1)

SUPPLY

NC

COIL

PULSE INPUT

NPN/PNP

2

1

3

PE

+

-

SENSOR

SUPPL

Y

LOAD

+5V

L+

(L+)-12V

COIL/PNP

39K

470

2.2K

SENSOR TYPE

COIL

NPN/PNP

DO2

DO3

OF

FO

N

Potentially

explosive area

Safe area

Intrinsic safety

barrier

Power supply

The position of switches "B" and "A" is indifferent.

Put the 2 switches "1" and "2" in

the ON position.

Fig. 8 : Connection between an SE30 Ex and a panel

version of the transmitter 8025 Universal.

English

33

34

11. mAinTEnAncE

Safety instructions

danger

risk of injury due to electrical voltage.

• Shut down the electrical power source of all the conduc-

tors and isolate it before carrying out work on the system.

• Observe all applicable accident protection and safety

regulations for electrical equipment.

risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain

the pipe before loosening the process connections.

risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before

loosening the process connections.

• Keep all easily flammable material and fluid away from

the device.

danger

risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident preven-

tion and safety relating to the use of aggressive fluids.

English

35

Warning

risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and

skilled staff with the appropriate tools.

• Ensure that the restart of the installation is controlled

after any interventions.

cleaning

note

the device may be damaged by the cleaning liquid.

• Clean the device with a cloth slightly dampened with

water or a cleaning liquid compatible with the materials

the device is made of.

English

35