Burkert Type SE30EX User Manual

Page 7

24

9. inSTAllATion AnD

commiSSioninG

Safety instructions

danger

risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain

the pipe before loosening the process connections.

risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before

loosening the process connections.

risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention

and safety relating to the use of hazardous products.

danger

risk of injury due to electrical voltage.

• Shut down the electrical power source of all the

conductors and isolate it before carrying out work on

the system.

• Observe all applicable accident protection and safety

regulations for electrical equipment.

English

25

Warning

risk of injury due to non-conforming installation.

• The electrical and fluid installation can only be carried out

by qualified and skilled staff with the appropriate tools.

• Observe mounting instructions of the fitting.

risk of injury due to an uncontrolled restart.

• Ensure that the restart of the installation is controlled

after any interventions on it.

Warning

risk of injury due to non-conforming commissioning.

Non conforming commissioning may lead to injuries and

damage the device and its surroundings.

• Before commissioning, make sure that the staff in

charge have read and fully understood the contents of

the operating instructions.

• In particular, observe the safety recommendations and

intended use.

• The device / the installation must only be commissio-

ned by suitably trained staff.

English

25

26

note

risk of damage to the device due to the environment

• Protect this device against electromagnetic interfe-

rence, ultraviolet rays and, when installed outdoors, the

effects of the climatic conditions.

To make sure the device operates correctly, plug in

and tighten the female connector.

installation onto the pipe

atex

Use only brass, stainless steel, aluminium or PVDF fit-

tings. Any other fittings are prohibited in explosive areas.

In firedamp mines use brass or stainless steel fittings

only, with a PVDF paddle-wheel for an S030 fitting.

Comply with the safety instructions and the "ATEX ins-

tructions notice" (chap. 6) for the type of fluid connection

that can be used depending on the place of installation

in potentially explosive atmospheres.

→

When installing the device, respect the instructions of

the S030 or S070 fittings operating instructions.

English

27

1

2

3

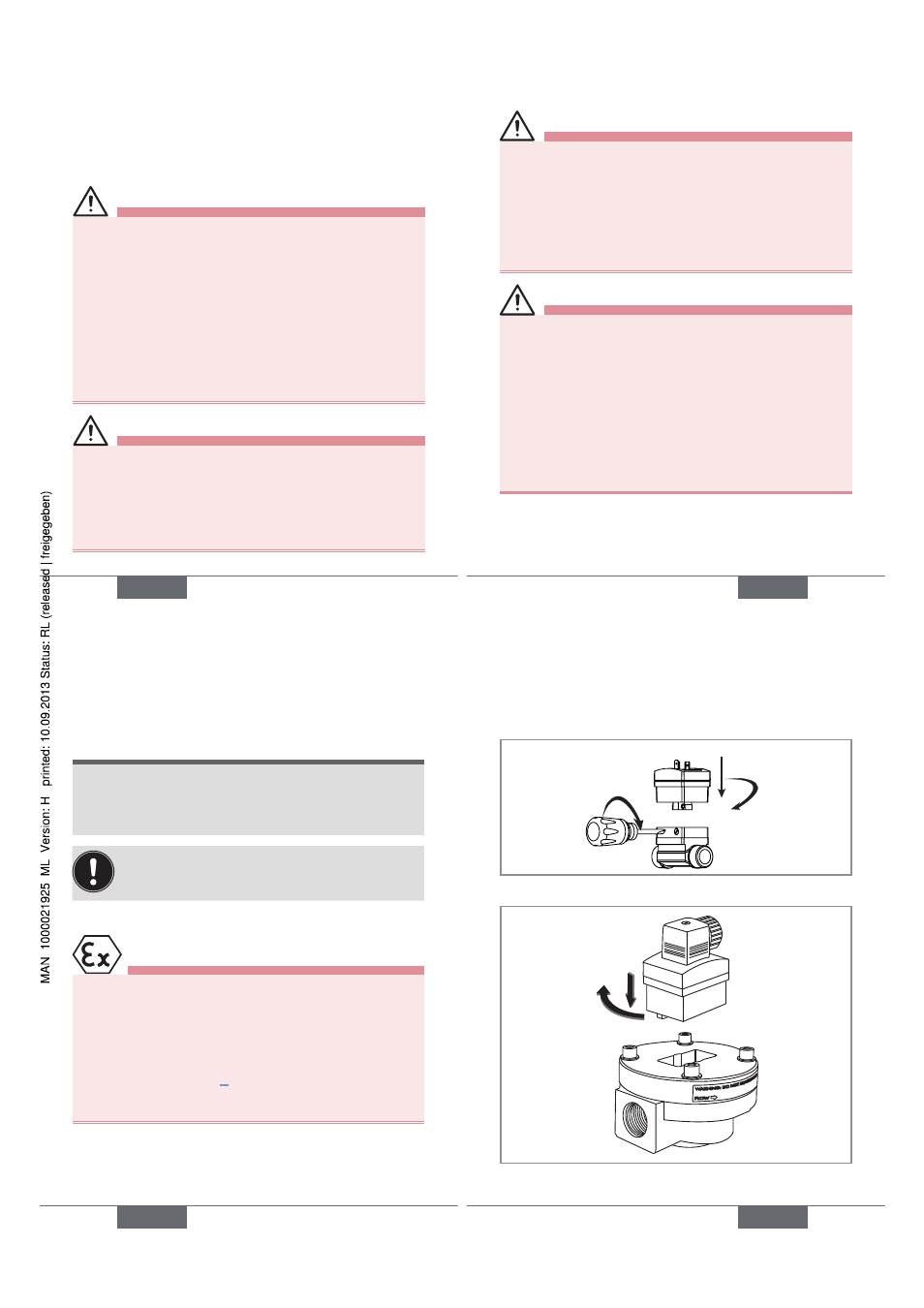

Fig. 2 : Mounting of the SE30 Ex onto an S030 fitting

1

2

Fig. 3 : Mounting of the SE30 Ex onto an S070 fitting

English

27