2 replacing the diaphragm – Burkert Type 2105 User Manual

Page 38

38

Repairs

Warning!

for control function i – danger if pilot pressure fails!

For control function I control and resetting occur pneumatically. If

the pressure fails, no defined position is reached.

▶ To ensure a controlled restart, first pressurize the product with

pilot pressure, then switch on the medium.

11.2 replacing the diaphragm

required spare part

• Diaphragm

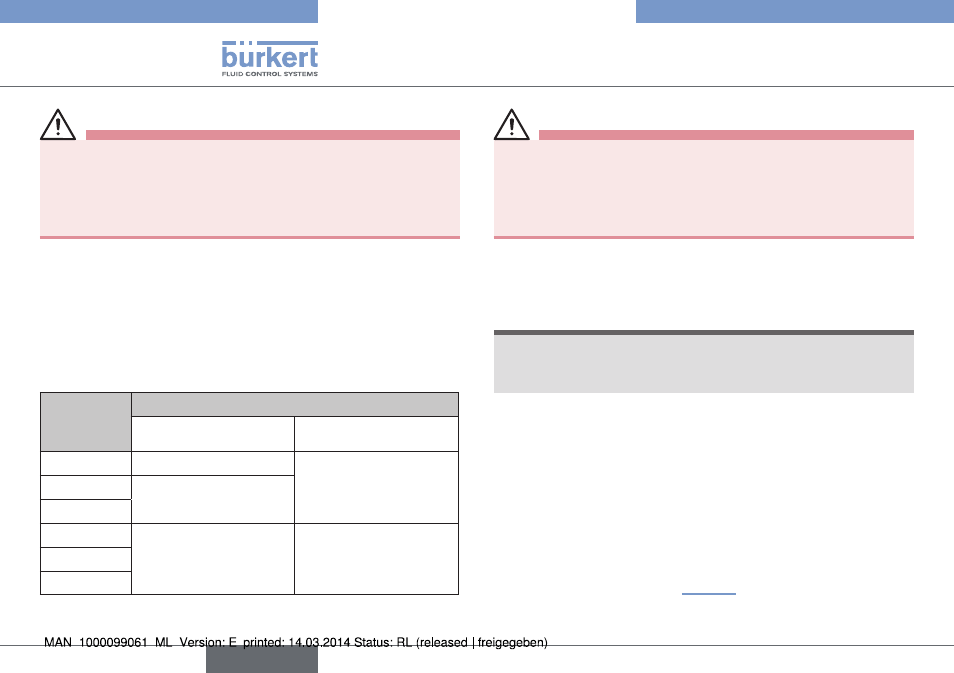

fastening types

Orifice dn

(diaphragm

size)

fastening types for diaphragms

ptfe

epdm / fkm

8

Diaphragm buttoned

Diaphragm buttoned

15

Diaphragm with bayonet

catch

20

25

Diaphragm with bayonet

catch

Diaphragm screwed in

40

50

Tab. 15: Fastening types for diaphragms

Danger!

risk of injury from discharge of medium and pressure!

It is dangerous to remove a product which is under pressure due

to the sudden release of pressure or discharge of medium.

▶ Before removing a product, switch off the pressure and vent the

lines.

replacement for control function a

→

Clamp the valve body in a holding product

(applies only to valves not yet installed).

noTiCe!

damage to the diaphragm or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→

Pressurize pilot air port 1 of the actuator with compressed air (5

bar): valve opens.

→

Loosen the four body screws.

→

Remove the actuator from the body.

→

Unbutton or unscrew old diaphragm. If attachment is with a

bayonet catch, remove the diaphragm by rotating it through 90°.

→

Install new diaphragm.

→

Align diaphragm.

the marker flap of the diaphragm must be perpendicular to

the direction of flow (see “Fig. 39”)!

→

Place actuator back on the body.

english

Type 2103, 2104, 2105