2 before installation – Burkert Type 2105 User Manual

Page 29

29

Installation

8.2

Before installation

• Before connecting the valve, ensure the pipelines are flush.

• The flow direction is optional.

8.2.1 installation position general

installation for self-drainage of the body

It is the responsibility of the installer and operator to

ensure self-drainage.

installation for leakage detection

One of the bores (in the actuator base) for monitoring

leakage must be at the lowest point.

8.2.2 installation position 2/2-way valve

type 2103

• The piston-controlled diaphragm valve can be installed in any

installation position, preferably with the actuator face up.

To ensure self-drainage:

→

Install body inclined by an angle α = 10° to 40° to the horizontal.

→

Observe an inclination angle of 1° – 5° to the line axis.

Forged and cast body: Mark on the body must point upwards

(12 o’clock position, see “Fig. 34”).

→

One of the bores (in the actuator base) for monitoring leakage

must be at the lowest point.

α

Angle α: 10° to 40°

Inclination to the line axis 1° ... 5°

Mark

Fig. 34: Installation position for self-drainage of the body

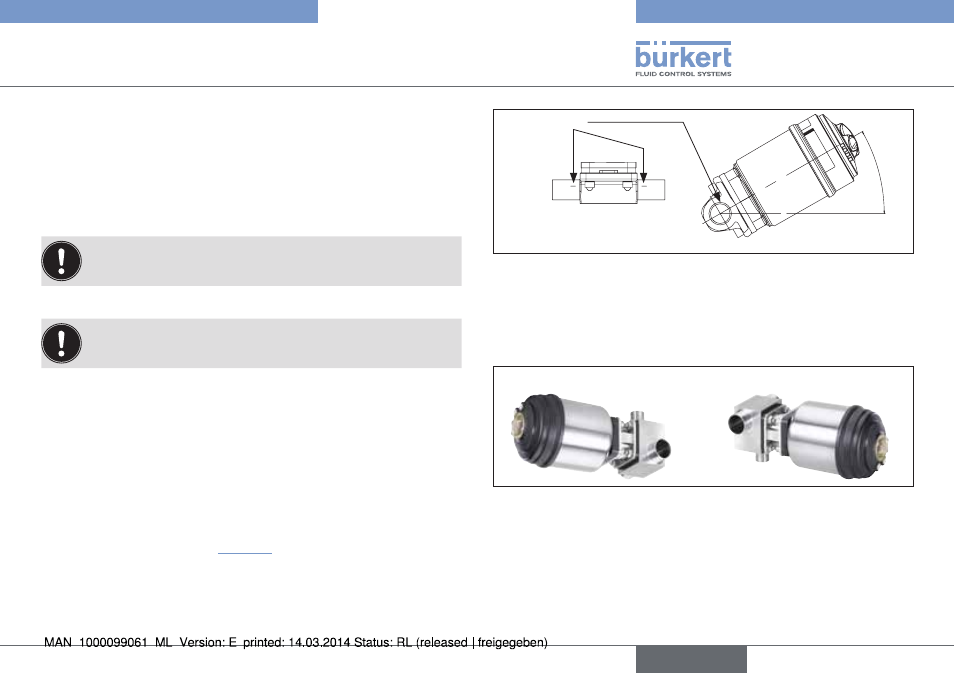

8.2.3 installation position T-valve type 2104

For the installation of the T-valves into circular pipelines, we

recommend the following installation positions:

When media is supplied:

When media is removed:

Fig. 35: Installation position type 2104

8.2.4 installation position tank bottom

valve type 2105

Preferably with the actuator to the bottom.

english

Type 2103, 2104, 2105