3 installation – Burkert Type 2105 User Manual

Page 30

30

Installation

8.2.5 preparatory work

→

Clean pipelines (sealing material, swarf, etc.).

→

Support and align pipelines.

products with Vg/Vs welded body:

noTe!

damage to the diaphragm or the actuator!

▶ Before welding in the body, remove the actuator.

remove the actuator from the valve body:

noTiCe!

damage to the diaphragm or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→

Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→

Remove actuator with diaphragm by loosening the body screws.

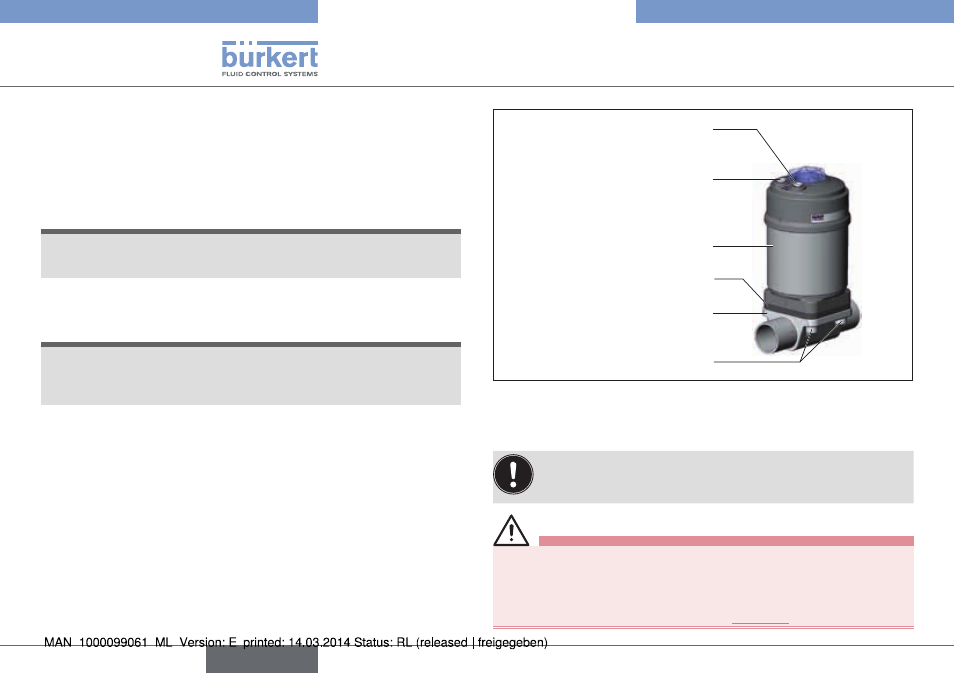

Actuator

Valve body

Air discharge connection CFA, CFB

Pilot air port CFI

Pilot air port CFA, CFB, CFI

2

1

Body screws (4x)

Diaphragm

Fig. 36: Installation

8.3

installation

If used in an aggressive environment, we recommend con-

veying all free pneumatic connections into a neutral atmos-

phere with the aid of a pneumatic hose.

Warning!

risk of injury from improper installation!

Non-observance of the tightening torque is dangerous as the product

may be damaged.

▶ Observe the tightening torque (see “Tab. 14”).

english

Type 2103, 2104, 2105