Brooks, Model 5850i, Table 4-1 bench troubleshooting – Brooks Instrument 5850i User Manual

Page 30

Brooks

®

Model 5850i

4-2

Section 4 Maintenance

Installation and Operation Manual

X-TMF-5850i-MFC-eng

Part Number: 541B108AAG

December, 2008

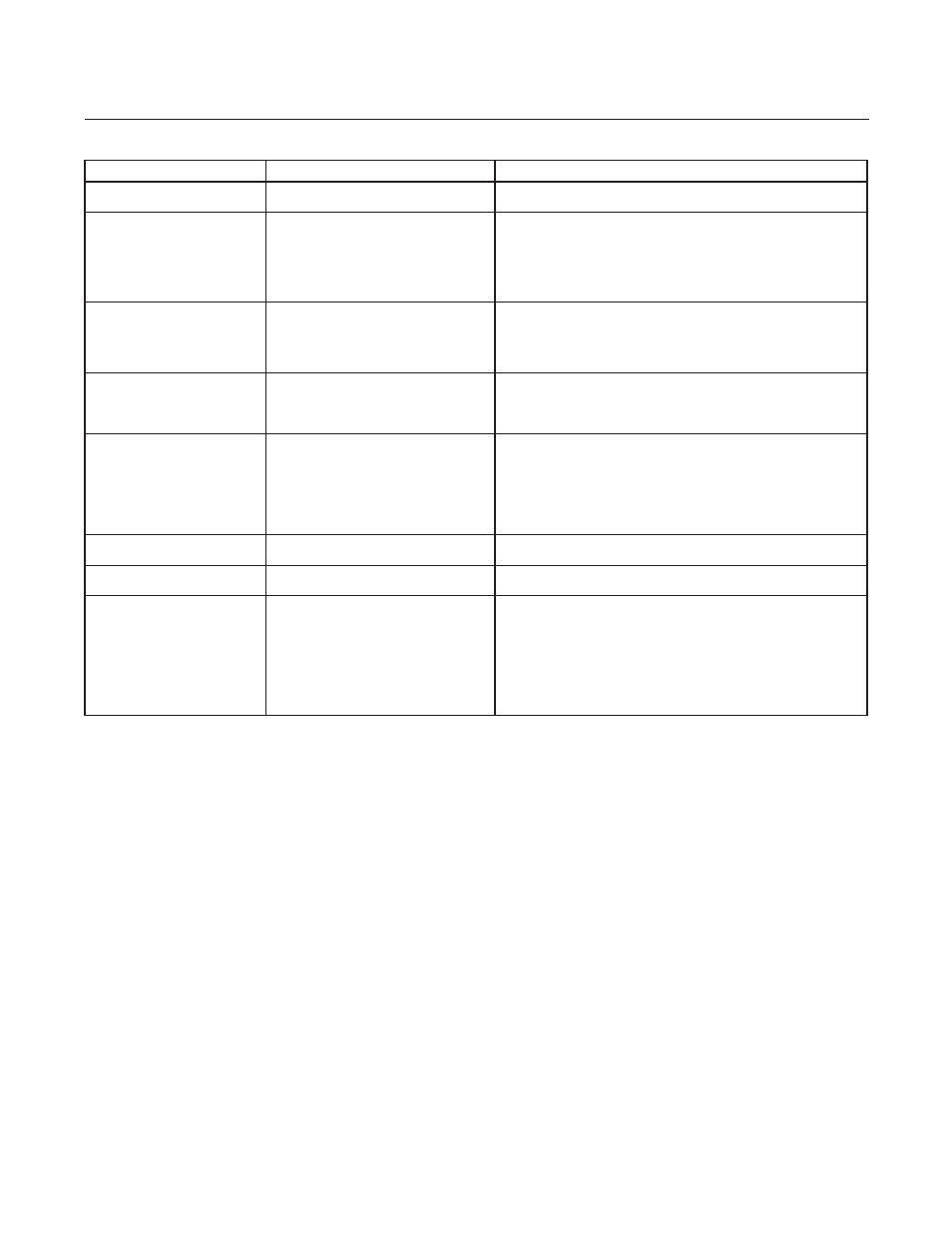

Trouble

Possible Cause

Check/Corrective Action

Actual flow overshoots setpoint by

Anticipate potentiometer out of adjustment.

Adjust anticipate potentiometer. Refer to Section 3-5 .

more than 5% full scale.

Output stays at zero regardless

Clogged Sensor. Refer to Section 4-4.

Clean sensor. Refer to cleaning.

of setpoint and there is no flow

through the controller.

Clogged Control Valve.

Check TP3 with the setpoint at 100%. If the voltage is greater than 11V, disassemble

and repair the control valve. Refer to Sections 4-4c and 2-10.

Valve override input is grounded.

Check valve override input (Pin 12)

Defective PC Board.

Replace PC Board. Refer to Section 4-4.

Output signal stays at +6.8V or 26 mA

Valve stuck open or leaky.

Clean and/or adjust control valve. Refer to cleaning procedure and/or Section 4-4C.

regardless of command and there

is flow through the controller.

+15V -28Vdc applied to the valve override input.

Check the valve override terminal. (Pin 12)

Defective PC Board.

Replace PC Board. Refer to Section 4-4.

Output signal follows setpoint

Leaky control valve.

Disassemble and repair valve. Refer to Section 4-4C.

at higher setpoints but will not go

below 2% (8% for all-metal seat).

Output signal follows setpoint

Insufficient inlet pressure or pressure drop.

Adjust pressure, inspect the filters and clean/replace as necessary.

at lower setpoints but does not reach

full scale.

Partially clogged sensor.

Check calibration. Refer to Section 3-4.

Partially clogged valve.

Disassemble and repair control valve. Refer to Section 4-4.

Valve out of adjustment.

Adjust valve. Refer to Section 4-4.

Valve guide spring failure.

Controller oscillates (see below).

Controller grossly out of calibration.

Partially clogged sensor.

Clean sensor, refer to the cleaning procedure.

Flow is higher than desired.

Controller grossly out of calibration.

Partially clogged restrictor.

Replace restrictor. Refer to Section 4-4.

Flow is lower than desired.

Controller oscillates.

Pressure drop or inlet pressure excessive.

Adjust pressures.

Oversized orifice.

Check orifice size. Refer to Section 4-6.

Valve out of adjustment.

Adjust valve. Refer to Section 4-4.

Anticipate potentiometer out of adjustment.

Adjust anticipate potentiometer. Refer to Section 3-5.

Faulty pressure regulator.

Check regulator output.

Defective PC Board.

Replace PC Board. Refer to Section 4-4.

the output signal will not zero properly, refer to the sensor trouble-

shooting section and check the sensor. If the sensor is electrically

functional, the printed circuit board is defective and will require

replacement.

2. Connect the controller to a source of the gas on which it was origi-

nally calibrated. Command 100% flow and adjust the inlet and outlet

pressures to the calibration conditions. Verify that the output signal

reaches and stabilizes at 5.00 volts or 20mA. Vary the setpoint over

the 2 to 100% range and verify that the output signal follows the

setpoint. Apply +15-28 volts to the valve override input (pin 12) and

verify that the output exceeds 100%. Connect the valve override pin

to ground and verify that the output signal falls below 2%. If possible,

connect a flow measurement device in series with the mass flow

controller to observe the actual flow behavior and verify the accuracy

of the mass flow controller. If the mass flow controller functions as

described above, it is functioning properly and the problem may lie

elsewhere.

Table 4-1 lists possible malfunctions which may be encountered during

bench troubleshooting.

Table 4-1 Bench Troubleshooting