6 example (xm, xh or xw conveyors), 3 start-up, 1 lubrication – FlexLink WL322 (322 мм) Монтаж User Manual

Page 38

Start-up and testing

34

5683EN-1

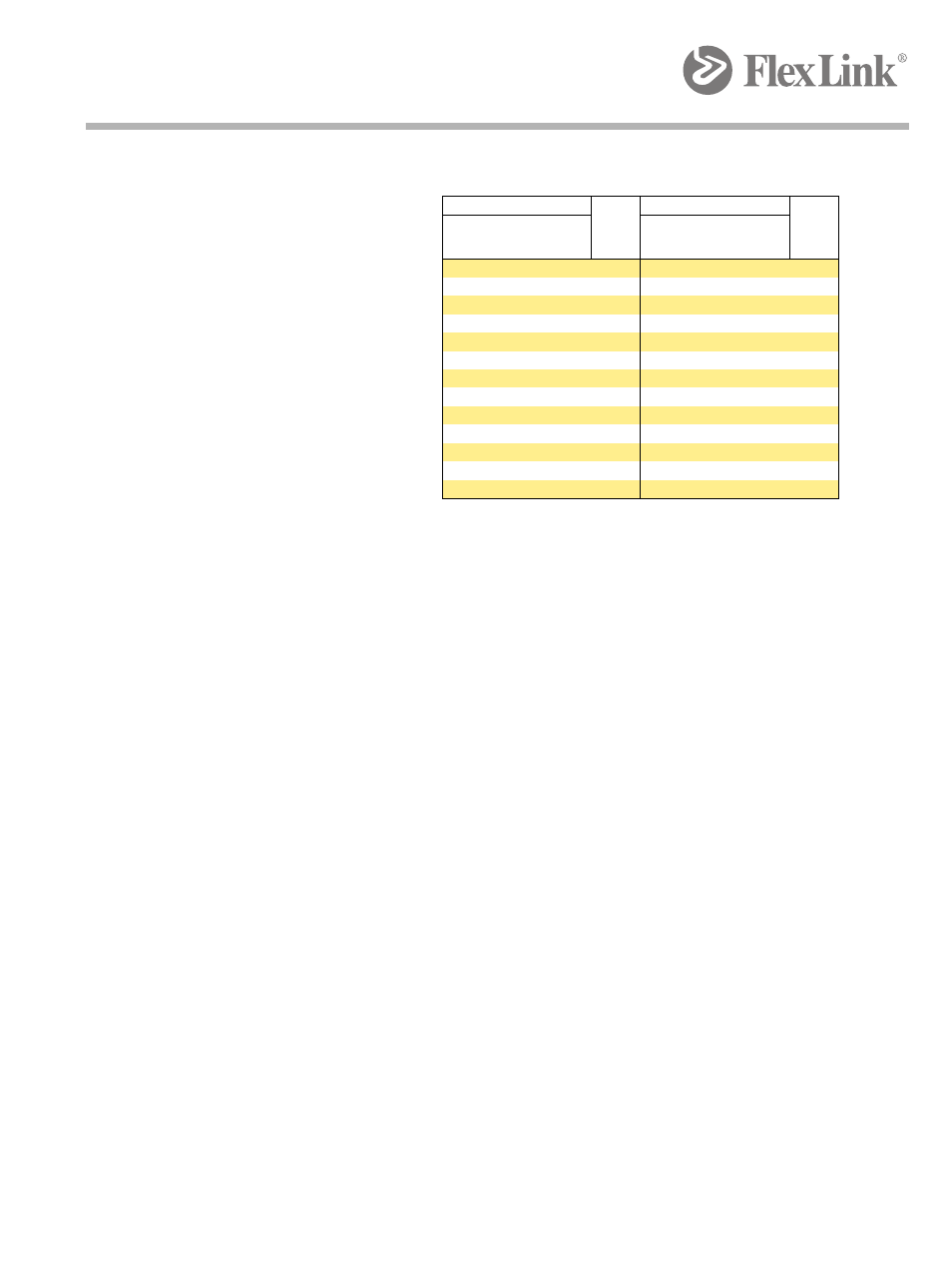

The values in the table are approximate and apply to new slip clutches.

F max (N)

F max (N)

XS

XL

XM

XH

XW

XK

X (div.)

XM

XH

XW

XK

X (div.)

450

450

100

19

1200

1200

1400

6

475

475

200

18

1300

1500

5

525

300

17

1400

1600

4

575

400

16

1525

1700

3

625

500

15

1800

2

675

600

14

1900

1

725

700

13

2000

0

775

800

12

2100

–1

825

900

11

2200

–2

875

1000

10

2300

–3

925

1100

9

2400

–4

1000

1200

8

2500

–5

1100

1300

7

12.2.6

Example (XM, XH or XW conveyors)

You wish to set the clutch so that it permits a maximum traction force

of 900 N. Above that load, the clutch should release.

From the table you find that the ring must be released at least 9 divisions

from hand-tightened position. Since the ring should be turned by complete

steps, you should select 9 steps. This corresponds to three quarters (¾) of

a full turn. The clutch will release at approximately 925 N. If you release the

ring by 10 divisions the clutch will release at 875 N.

Also see formulas for chain tension calculations in the main conveyor cat-

alogue, chapter "Multiflexing conveyors", section "Engineering guidelines".

12.3

Start-up

12.3.1

Lubrication

The conveyor chain is lubrication-free. However, for some specific applica-

tions where the operating environment is particularly hostile, regular lubri-

cation of the slide rail/conveyor chain will result in a lower coefficient of fric-

tion, longer life and reduced running costs. Use a silicone-based lubricant

(LDSS 450 or an equivalent lubricant).