Inspection – conveyor chains – FlexLink X45 (43 мм) Тех. обслуживание User Manual

Page 9

Maintenance

9

Inspection – conveyor chains

Conveyor chains

The most common types of conveyor chains are:

•

Plain conveyor chains.

.

•

Chain with cleats for inclined or vertical conveyor sec-

tions. The cleats are generally spread over the chain

at a predetermined distance.

•

Chain with flexible cleats for vertical wedge convey-

ors.

•

Chain with friction surface for conveyors with an

incline up to 30°. The friction surfaces are normally

distributed over the chain at a predetermined dis-

tance.

Cleated, friction and wedge chains

Cleated chains, friction chains and wedge chains, or

other special chains should be inspected regularly, and

any defective links replaced or cleaned.

Warning

Only warm water (50°C), with soap if necessary, may be

used for cleaning conveyor chains.

•

Check the guards on cleated chain conveyors.

Checking the tension of conveyor chain

The chain is made of elastic material. The chain eventu-

ally stretches as the material creeps. The extent of the

stretch depends on the traction force in the chain. The

stretch shows itself as slack on the return side of the

drive unit.

The tension of the conveyor chain should be checked

after 50, 250, 500 hours of operation and thereafter every

500 hours.

In operation there will be some slack in the conveyor

chain. How much slack is acceptable depends on the

length of the conveyor chain. The most suitable places to

check the slack in the chain are at intermediate or end

drive units.

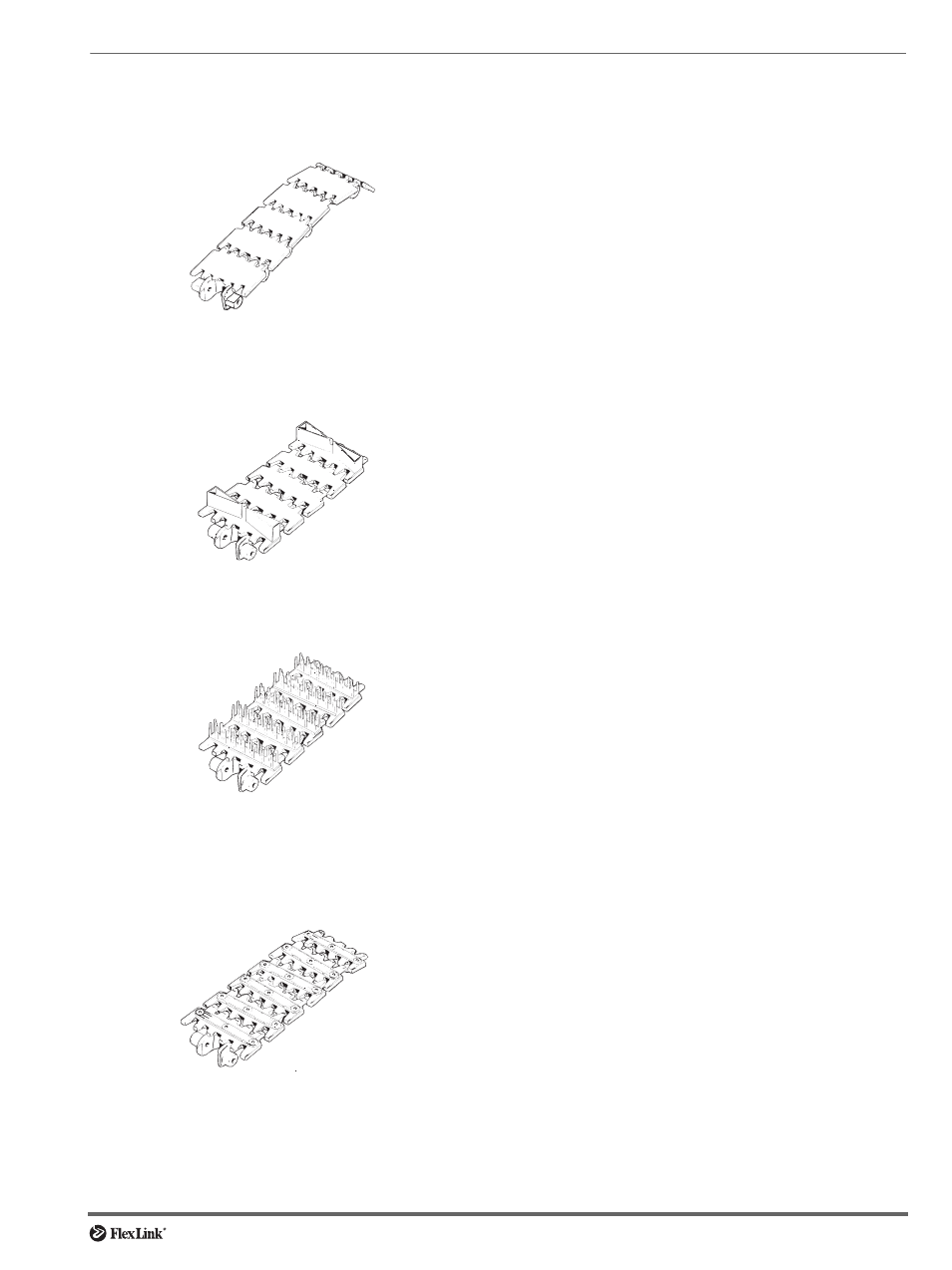

Plain conveyor chain

Cleated chain

Chain with flexible cleats

Chain with friction surface

- X45H (43 мм) Тех. обслуживание XS (45 мм) Тех. обслуживание XL (65 мм) Тех. обслуживание X85 (85 мм) Тех. обслуживание XH (105 мм) Тех. обслуживание XK (105 мм) Тех. обслуживание X180 (182 мм) Тех. обслуживание X300 (300 мм) Тех. обслуживание XW (300–1200 мм) Тех. обслуживание X45E (макс. 250 г) Тех. обслуживание XL (макс. 3 кг) Тех. обслуживание X85 (макс. 10 кг) Тех. обслуживание XK (макс. 30 кг) Тех. обслуживание