Anchoring slide rail – FlexLink X45 (43 мм) Тех. обслуживание User Manual

Page 15

Maintenance

15

Anchoring slide rail

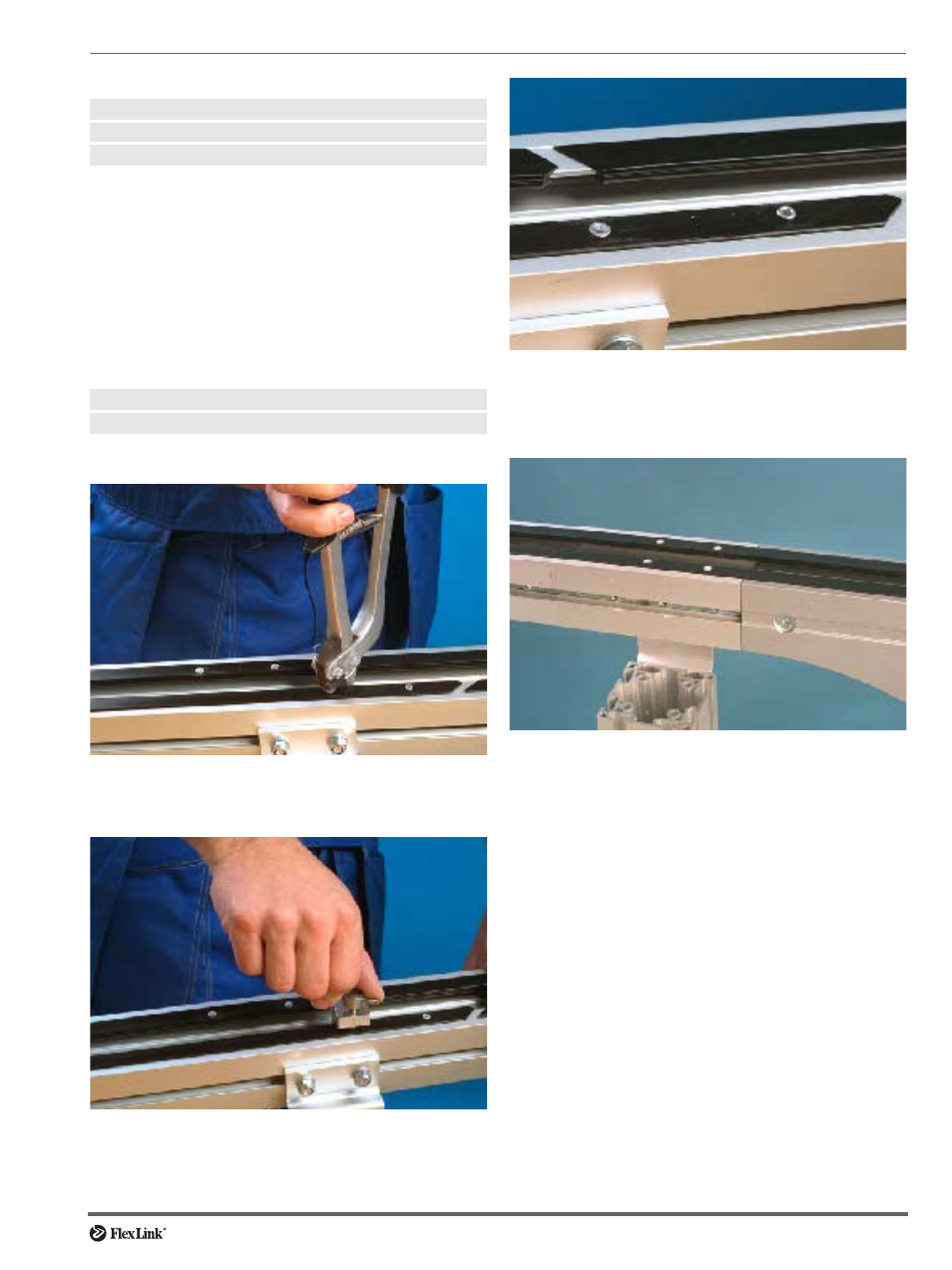

Fixing slide rail to the conveyor beam

The beginning of each slide rail section must be fixed to

the beam, since the chain will cause the slide rail to be

pushed forward. Slide rail which moves into a wheel bend

or a drive unit can block the chain completely.

There are two different methods for fixing slide rail to

the conveyor beam: using aluminium rivets or plastic

screws. Either method can be used, but the riveting

method is more secure if the conveyor will run with high

operational speed or be heavily loaded.

Method 1: Using aluminium rivets

Mounting:

Hand drill

Drill fixture for slide rail

4,2 mm (XS: 3,2 mm)

Countersink

Rivet crimping pliers/rivet crimping clamp

Aluminium rivets

1 Insert rivets in the holes, using rivet crimping pliers or

a rivet crimping clamp. For type of rivet, see table on

previous page.

2 If working space is limited, the rivet crimping clamp

might be easier to use. The two crimping tools per-

form the same task, but the pliers are more efficient

and easier to use.

3 Check that the rivets do not protrude over the surface

of the slide rail.

Check both top and underneath surface of slide rail for

protruding metal.

4 Keep a distance of approximately 30 mm between riv-

ets and idler unit. This is in case the idler unit has to

be removed after conveyor system assembly.

correct

wrong

- X45H (43 мм) Тех. обслуживание XS (45 мм) Тех. обслуживание XL (65 мм) Тех. обслуживание X85 (85 мм) Тех. обслуживание XH (105 мм) Тех. обслуживание XK (105 мм) Тех. обслуживание X180 (182 мм) Тех. обслуживание X300 (300 мм) Тех. обслуживание XW (300–1200 мм) Тех. обслуживание X45E (макс. 250 г) Тех. обслуживание XL (макс. 3 кг) Тех. обслуживание X85 (макс. 10 кг) Тех. обслуживание XK (макс. 30 кг) Тех. обслуживание