Replacement of worn parts – conveyor chain – FlexLink X45 (43 мм) Тех. обслуживание User Manual

Page 13

Maintenance

13

Replacement of worn parts – conveyor chain

Removal of conveyor chain

1 Ensure that the power to the drive motor is discon-

nected.

2 Disengage the motor; there are various methods

depending on the type of drive unit:

— Detach the slip clutch.

— Remove the roller chain.

— Disengage the gear from the drive wheel.

3 Split the chain by removing the steel pin from the

pivot. Use the special tool for insertion/removal.

4 Pull out the chain.

Fitting the conveyor chain

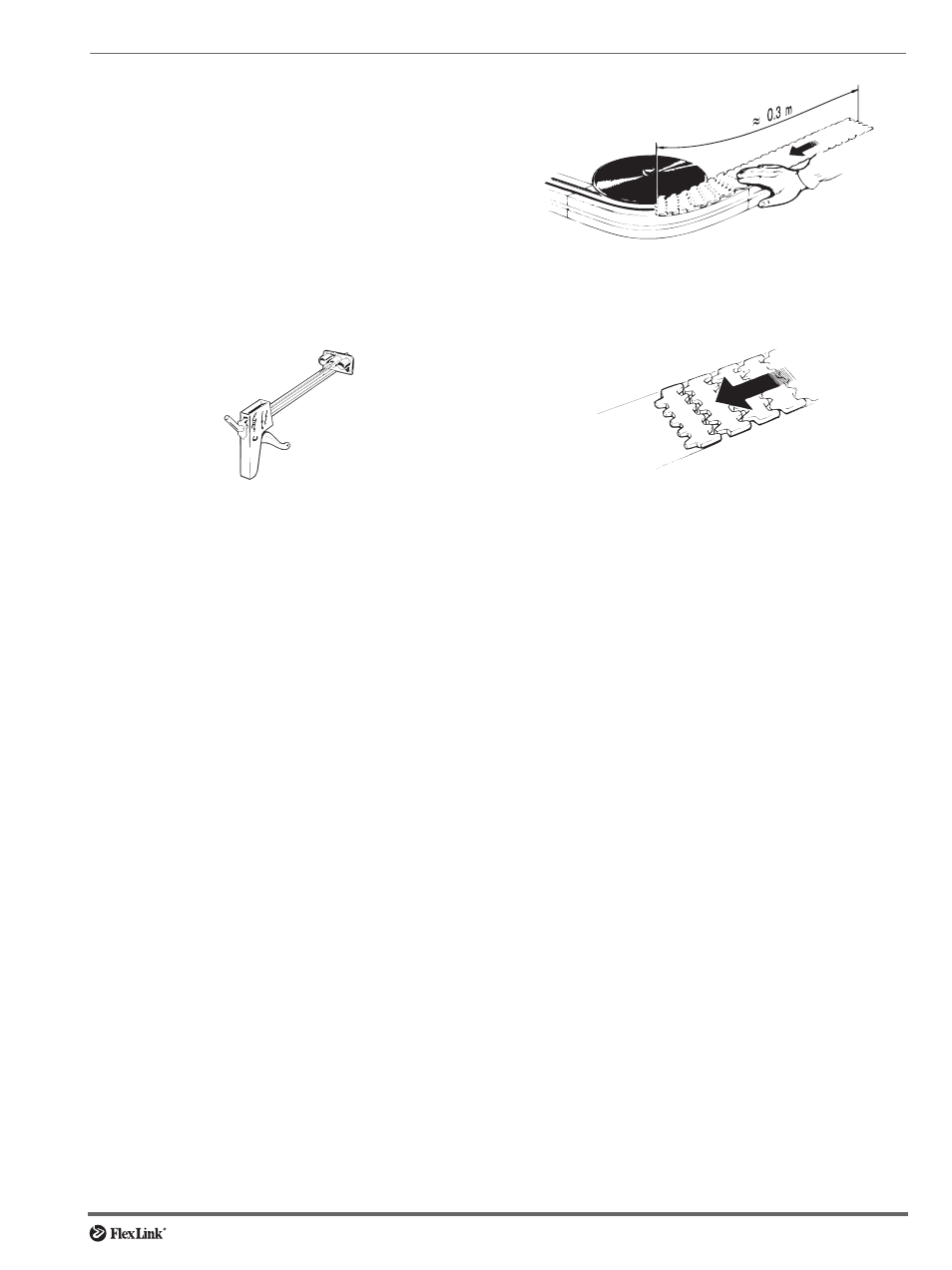

1 Run a sample (approx. 0.3 m) of conveyor chain

through the installation in the direction of the con-

veyor. Check that the chain moves easily and cor-

rectly through the bends and idler ends. Check at the

same time that there is enough space for the chain.

2 Put the new conveyor chain in place. Check that the

chain direction corresponds to the conveyor direction.

Note

Be careful that the first link of the conveyor chain does

not damage the slide rails.

Immediately investigate the reasons for any jamming and

take immediate action.

3 Shorten the conveyor chain to the right length. Fit the

pivot and the steel pin, using the special pin inser-

tion/removal tool.

After fitting, check that the steel pin is centered and

that the chain can easily bend in the fitted link.

4 Check that the slack is not excessive. See “Checking

the tension of conveyor chain” on page 9.

Pin insertion/removal tool

Sample for checking conveyor chain space

The conveyor chain direction

- X45H (43 мм) Тех. обслуживание XS (45 мм) Тех. обслуживание XL (65 мм) Тех. обслуживание X85 (85 мм) Тех. обслуживание XH (105 мм) Тех. обслуживание XK (105 мм) Тех. обслуживание X180 (182 мм) Тех. обслуживание X300 (300 мм) Тех. обслуживание XW (300–1200 мм) Тех. обслуживание X45E (макс. 250 г) Тех. обслуживание XL (макс. 3 кг) Тех. обслуживание X85 (макс. 10 кг) Тех. обслуживание XK (макс. 30 кг) Тех. обслуживание