Replacement of worn parts – slide rails – FlexLink X45 (43 мм) Тех. обслуживание User Manual

Page 14

14

Maintenance

Replacement of worn parts – slide rails

Replacing slide rails

It is very important to assemble slide rails correctly to

ensure smooth system operation.

Follow the illustrated instructions on the following

pages carefully. Observe the following points:

•

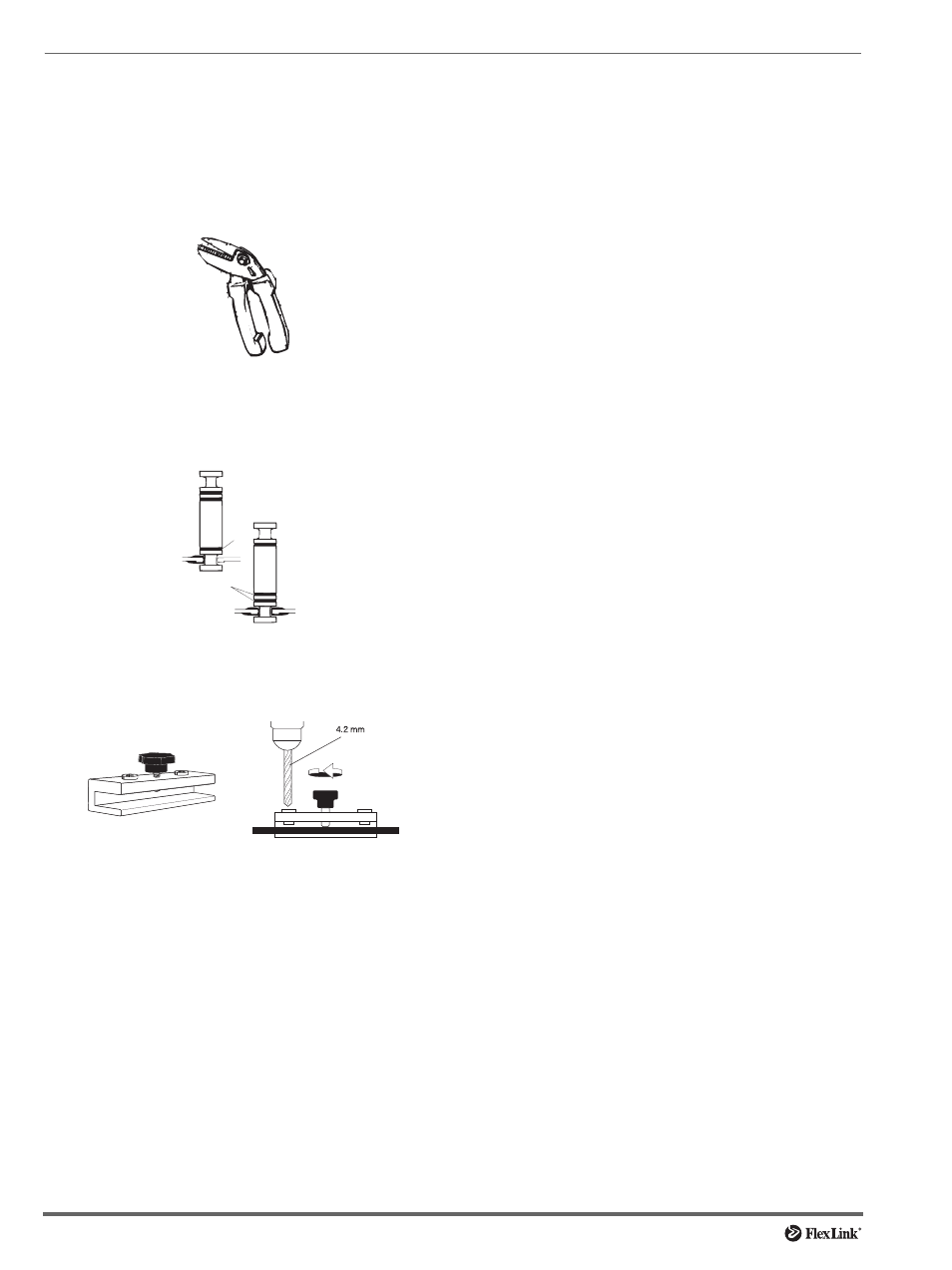

Single-cut pliers are suitable tools for cutting the slide

rails.

•

Use mounting tool for slide rail XLMR 140,

XMMR 140, XHMR 200, or XKMR 200.

•

Use drill fixture 3920500. The distance between

anchor points must be 50 mm.

•

Use a high quality drill bit to avoid forming a shoulder,

preferably one which is intended for drilling alumin-

ium.

•

Use XLAH 4×6/XLAH 3×6 rivets.

When fitting the slide rails with rivets, the fitting instruc-

tions on page 15 must be followed.

•

The joints on the slide rails must have a distance of

100 mm between them. The joints should be laid out

as in the picture with a gap of approx. 10 mm between

the rails.

•

Joints may not be positioned in bends, or in the tran-

sition between two sections of beams.

•

The slide rails should normally be approximately 5 m

long on a straight conveyor beam. In a bend, the max-

imum length of slide rail should be 3 m.

•

The joints should be positioned a minimum of 500 mm

before an idler end unit, drive unit or vertical bend.

The slide rail must overlap the recess in the idler end

and drive unit.

•

The inner slide rail after a wheel bend must be cut so

that the cut surface is parallel to the wheel. In front of

the wheel bend, the slide rail will normally be cut at

45°.

Note

Check the final slide rails visually, as well as running a

section of conveyor chain through the installation.

An alternative to the aluminium rivets, is to use the plastic

screws XLAG 5 (XWAG 5 for XK). See page 16 for fitting

instructions. The holes for the plastic screws are

threaded with a tap.

Single cut pliers

Mounting tool for slide rail

Drill fixture 3920500

1

2

XLMR 140

XMMR 140

XHMR 200

XKMR 200

∅

- X45H (43 мм) Тех. обслуживание XS (45 мм) Тех. обслуживание XL (65 мм) Тех. обслуживание X85 (85 мм) Тех. обслуживание XH (105 мм) Тех. обслуживание XK (105 мм) Тех. обслуживание X180 (182 мм) Тех. обслуживание X300 (300 мм) Тех. обслуживание XW (300–1200 мм) Тех. обслуживание X45E (макс. 250 г) Тех. обслуживание XL (макс. 3 кг) Тех. обслуживание X85 (макс. 10 кг) Тех. обслуживание XK (макс. 30 кг) Тех. обслуживание