Inspection – drive units – FlexLink X45 (43 мм) Тех. обслуживание User Manual

Page 8

8

Maintenance

Inspection – drive units

Roller chain transmission

The roller chain transmission should be checked and

lubricated after 50, 250, 500 hours of operation, and then

every 500 hours.

If the roller chain transmission is not fitted with a chain

tensioner the chain tension should be checked on this

occasion.

At the same time as the roller chain tension is

checked, the chain must also be lubricated with a suita-

ble chain spray or similar.

If the transmission is fitted with a chain tensioner,

lubrication should only be carried out at the stated inter-

vals. The condition of the chain tensioner must be

checked at the same time as the lubricating is done.

Note

The discs in the slip clutch must be kept free from oil and

grease.

Worm gear motor and geared motor

The worm gear or geared motor is checked in accord-

ance with the instructions from the relevant supplier.

Guide for the conveyor chain

The purpose of the guide for the conveyor chain is to

guide the return chain correctly into the drive unit.

Fully enclosed drive units do not have guides. On

these, no slack is permitted at the drive unit since the

conveyor chain is being controlled all the time. Special

attention must be given to chain elongation in conveyors

of this configuration.

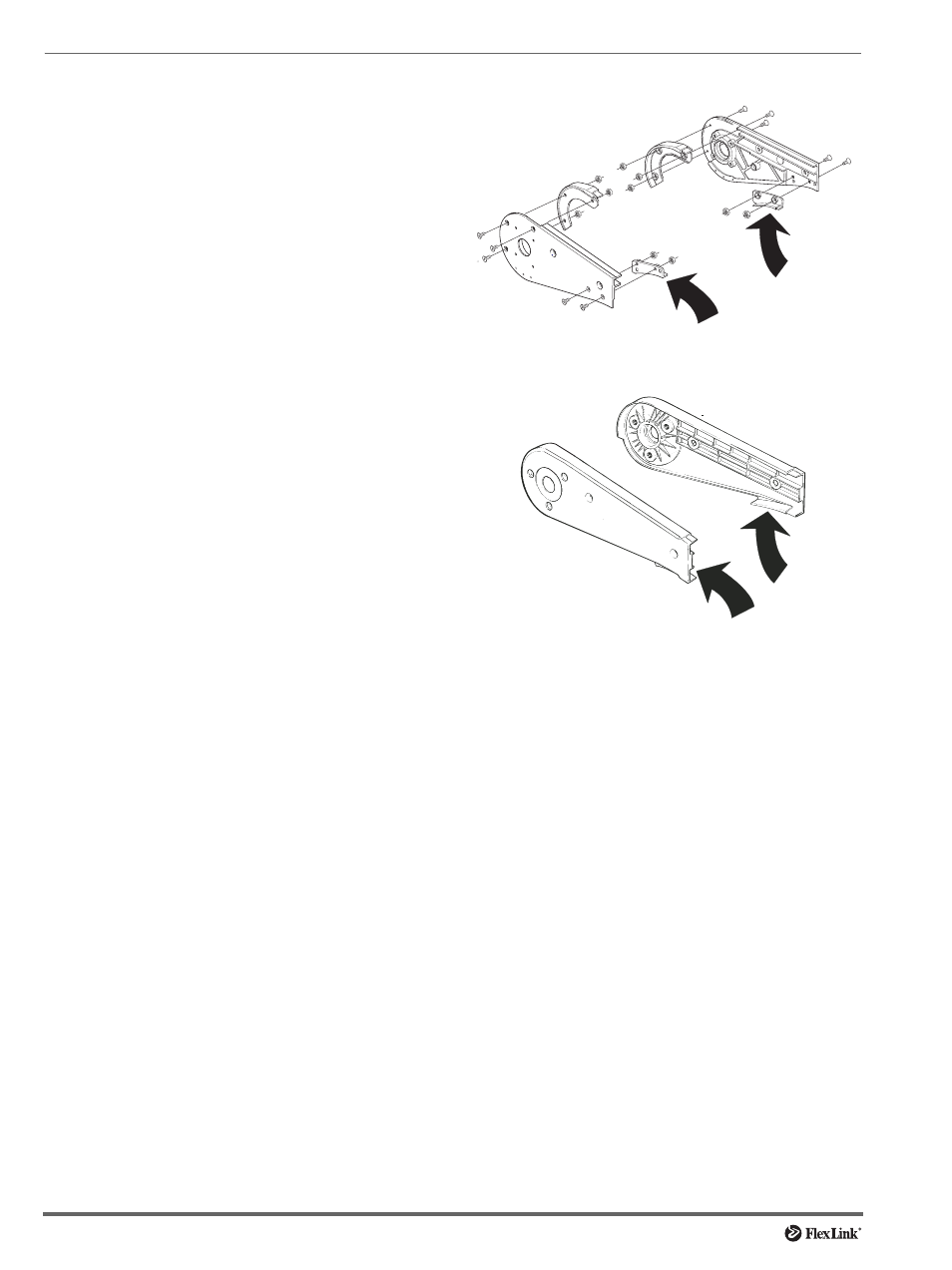

If guides are fitted they can be of two different types:

•

Loose disposable guides in plastic.

•

Guides integrated into the ends of the drive unit...

General checks on drive unit

Carry out a general inspection of the drive unit.

•

Check particularly that the protective covers for the

roller chains are complete and firmly in place.

•

Replace damaged/worn parts.

Replaceable chain guides

Chain guides integrated into ends.

- X45H (43 мм) Тех. обслуживание XS (45 мм) Тех. обслуживание XL (65 мм) Тех. обслуживание X85 (85 мм) Тех. обслуживание XH (105 мм) Тех. обслуживание XK (105 мм) Тех. обслуживание X180 (182 мм) Тех. обслуживание X300 (300 мм) Тех. обслуживание XW (300–1200 мм) Тех. обслуживание X45E (макс. 250 г) Тех. обслуживание XL (макс. 3 кг) Тех. обслуживание X85 (макс. 10 кг) Тех. обслуживание XK (макс. 30 кг) Тех. обслуживание